Reactor and method used for preparing aluminum hydroxide

An aluminum hydroxide and reactor technology, which is applied in the field of reactors for preparing aluminum hydroxide, can solve the problems of blockage of gas distribution pipes and distribution plates, gas utilization rate needs to be further improved, and uneven gas distribution, etc., and meets equipment requirements. No pollution, saving equipment investment, uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

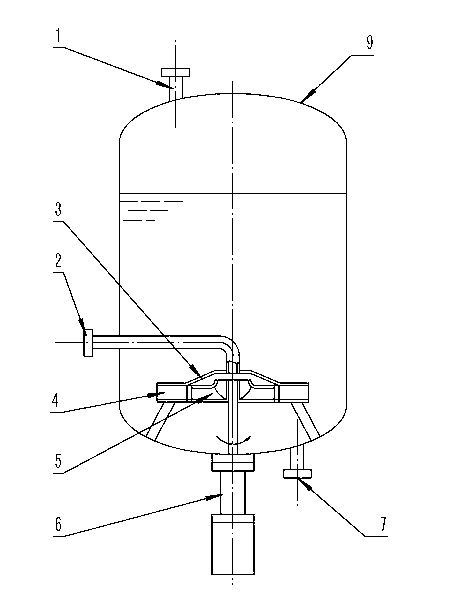

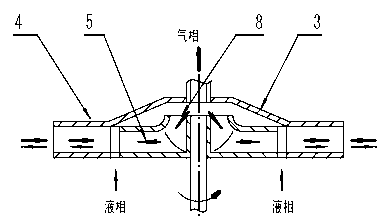

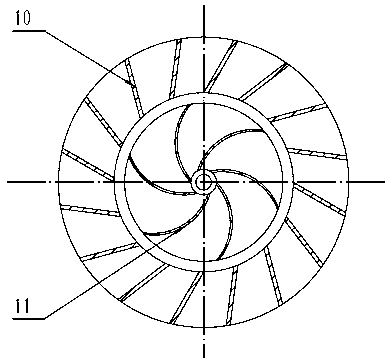

[0039] Formulated with Al 2 o 3 A sodium metaaluminate solution with a concentration of 25g / 1000mL is added to the reactor of the present invention, the reactor is started up, and after the impeller speed reaches 500 rpm, CO with a volume concentration of 55% is introduced into the reactor. 2 Gas, the temperature in the reactor is controlled at 30°C, when the pH value of the solution in the reactor reaches 10.5, stop feeding CO 2 Gas, reduce the rotating speed of the impeller to 200 rpm, and carry out the aging process, the aging temperature is controlled at 30°C, and the aging time is 40 minutes. After the aging results, the slurry was taken out from the reactor and filtered, the filter cake was washed with deionized water until the pH value = 7.0, and the filter cake was dried at 110°C for 10 hours to obtain the aluminum hydroxide dry glue A of the present invention. The obtained aluminum hydroxide dry glue was roasted at 550°C for 4 hours and then sampled and analyzed. Th...

Embodiment 2

[0041] Formulated with Al 2 o 3 Add sodium metaaluminate solution with a concentration of 35g / 1000mL into the reactor of the present invention, start the reactor, and after the impeller speed reaches 3000 rpm, feed CO with a volume concentration of 90% into the reactor. 2 Gas, the temperature in the reactor is controlled at 18°C, when the pH value of the solution in the reactor reaches 10.0, stop feeding CO 2 Gas, reduce the rotating speed of the impeller to 800 rev / min, carry out the aging process, the aging temperature is controlled at 18 ℃, and the aging time is 30 minutes. After the aging results, the slurry was taken out from the reactor and filtered, the filter cake was washed with deionized water until the pH value = 7.5, and the filter cake was dried at 150°C for 6 hours to obtain the aluminum hydroxide dry glue B of the present invention. The obtained aluminum hydroxide dry glue was roasted at 550°C for 4 hours and then sampled and analyzed. The properties of the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com