PBT (Polybutylece Terephthalate) plastic used for automotive interiors and preparation method thereof

A technology for automobile interior parts and plastics, which is applied to the field of antibacterial PBT plastics for automobile interior parts and its preparation, can solve the problems of difficulty, uneven dispersion of antibacterial agents, low safety performance, etc., so as to meet environmental protection requirements and reduce toxic by-products. possible, safe antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

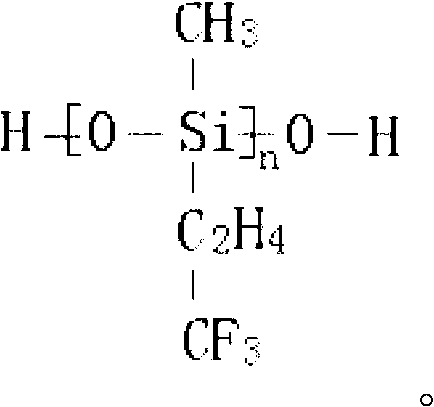

Method used

Image

Examples

Embodiment 1

[0042] After weighing each raw material according to the data corresponding to Example 1 in Table 1, add each component into a high-speed mixer, control the rotation speed at 300-400 rpm at room temperature, mix for 5-10 minutes, and transfer to the screw extruder after taking it out. Extruding and granulating at a temperature of 190-240° C. in the exiting machine to obtain the antibacterial PBT plastic for automotive interior parts.

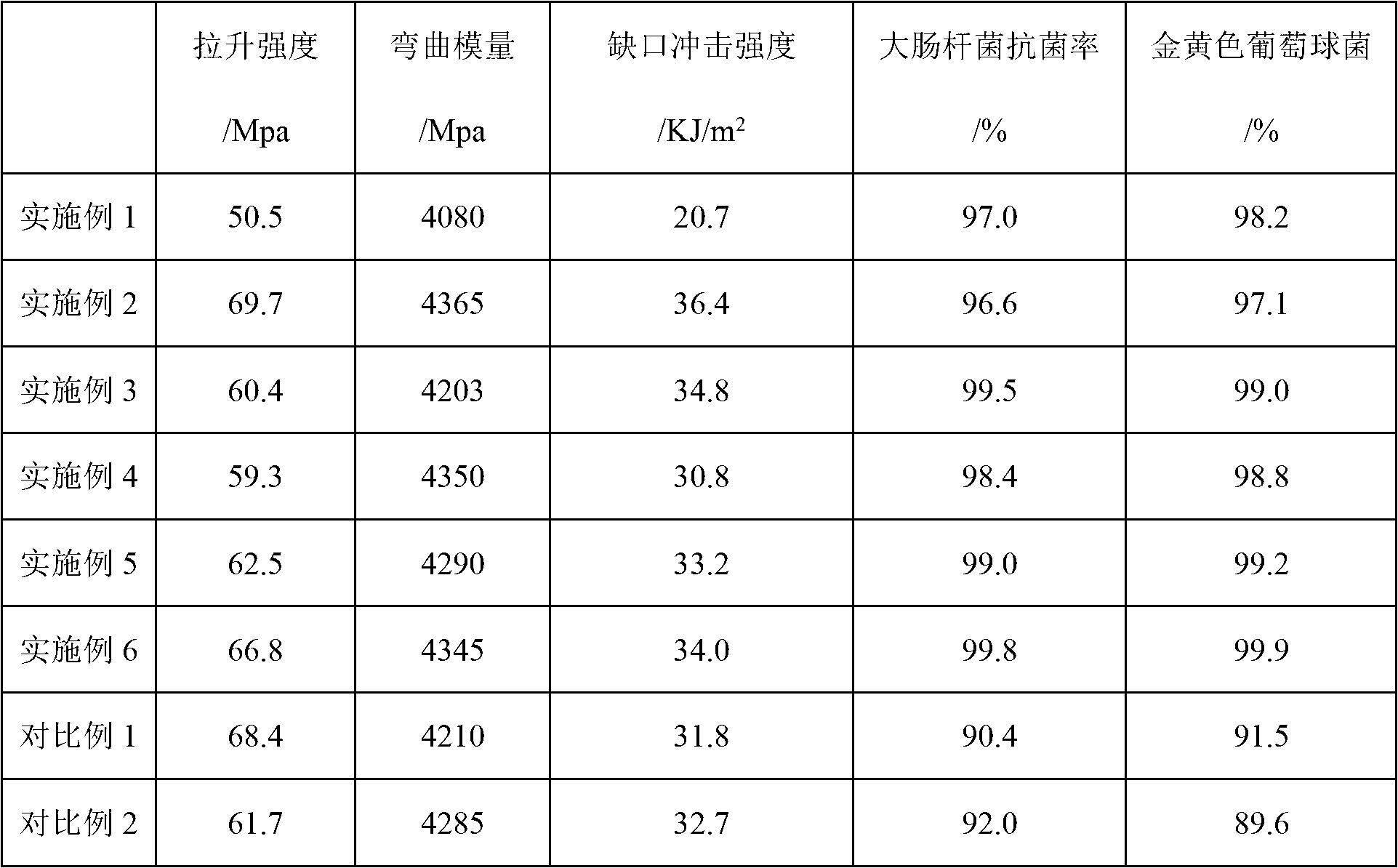

[0043] Table 1: Formula table of antibacterial PBT plastics for automotive interior parts Unit: kg

[0044]

[0045] In Table 1, the selected PBT resin is PBTGX-121 produced by Sinopec Yizheng Chemical Fiber Co., Ltd.; the selected glass fiber is the alkali-free short glass fiber produced by Hengshui Yixing Fiberglass Co., Ltd.; -80nm; nano-silver oxide, the particle size is 10-80nm; nano-copper oxide, the particle size is 10-80nm.

Embodiment 2

[0047] Each raw material was weighed according to the data corresponding to Example 2 in Table 1. The method described in Example 1 was adopted to prepare the antibacterial PBT plastics for automotive interior parts.

Embodiment 3

[0049] Each raw material was weighed according to the data corresponding to Example 3 in Table 1. The method described in Example 1 was adopted to prepare the antibacterial PBT plastics for automotive interior parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com