Resin composition and prepreg and laminate manufactured by using same

A resin composition and prepreg technology, used in the fields of high-frequency, high-speed and high-density interconnection, integrated circuit packaging, and electronic materials, can solve the problems of inability to form homogeneous resin, precipitation, etc., and achieve excellent heat resistance, good resistance Effects of thermal properties and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

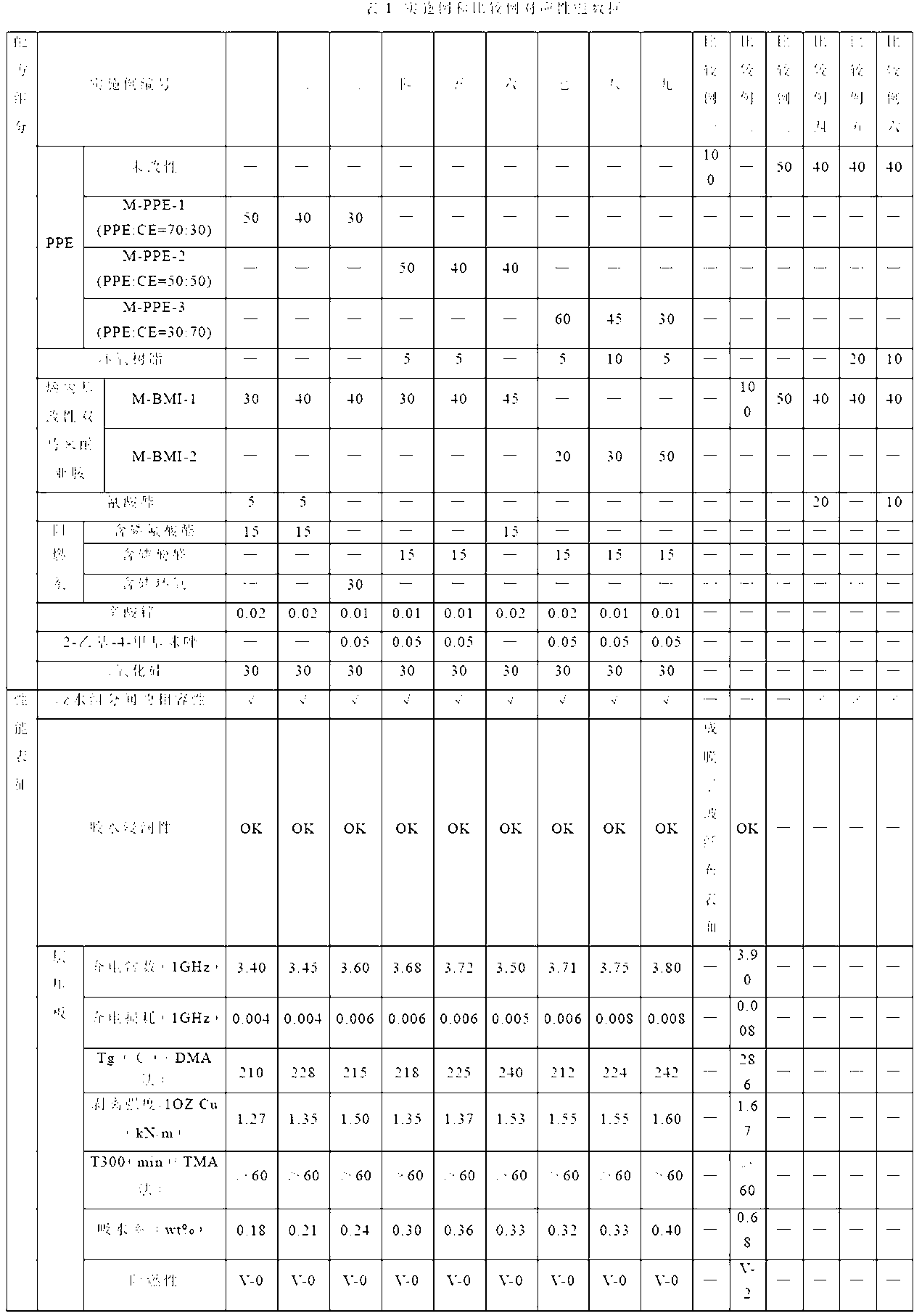

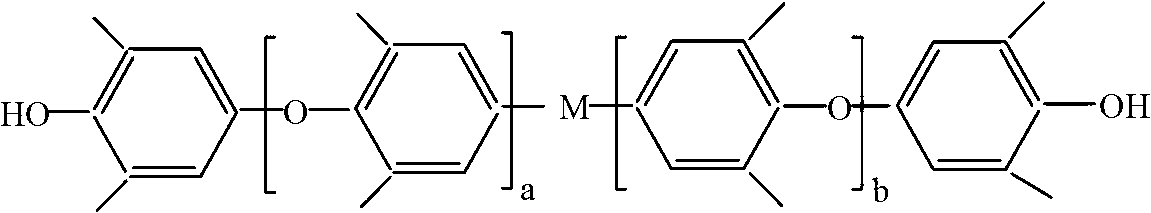

[0049] Weigh 140g of double-terminated hydroxyl low molecular weight polyphenylene ether resin in a beaker, add methyl ethyl ketone to dissolve it completely, add 60g of bisphenol A cyanate resin, and react in an oil bath at 120°C for 70min to obtain a viscous The cyanate ester modified polyphenylene ether resin prepolymer, the number average molecular weight is 5500 ~ 7000g / mol, recorded as M-PPE-1, ready for use.

Synthetic example 2

[0051] Weigh 100g of double-terminated hydroxyl low molecular weight polyphenylene ether resin in a beaker, add methyl ethyl ketone to dissolve it completely, add 100g of bisphenol A cyanate resin, and react in an oil bath at 130°C for 75min to obtain a viscous The cyanate ester modified polyphenylene ether resin prepolymer, the number average molecular weight is 4200 ~ 6000g / mol, recorded as M-PPE-2, ready for use.

Synthetic example 3

[0053] Weigh 60g of double-terminated hydroxyl low molecular weight polyphenylene ether resin in a beaker, add methyl ethyl ketone to dissolve it completely, add 140g of dicyclopentadiene type cyanate resin, and react in an oil bath at 150°C for 100min to obtain a viscous A cyanate-modified polyphenylene ether resin prepolymer with a number-average molecular weight of 3000-5000 g / mol, recorded as M-PPE-3, for use.

[0054] Synthesis of Allyl Modified Bismaleimide Resin

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com