Method for improving low-carbon aluminum killed steel blank hot cracks by adopting low-voltage pulse current

A low-carbon aluminum-killed steel, low-pressure pulse technology is applied in the field of improving hot-feeding cracks in billets, which can solve problems such as high production costs, billet heat loss, heat loss, etc., achieve environmental protection, safety, billet defects, and improve high-temperature mechanical properties. , The effect of reducing cracks by heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

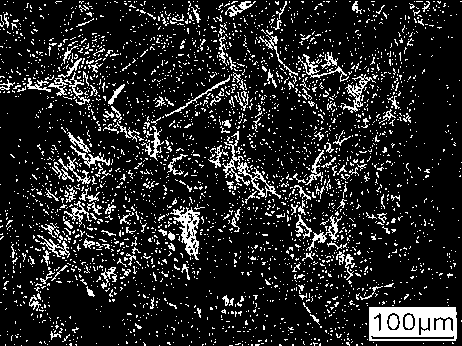

[0027] The material of this example is 16Mn steel (its main chemical composition is: 0.102%C, 0.384%Si, 1.40%Mn, 0.019%P, 0.007%S, 0.031%Al, 0.0055%N), first use the intermediate frequency vacuum induction furnace Smelting and casting to get 16Mn slab, then cut the slab into small samples, connect to the pulse power supply device through the wire, then put the sample into the box-type resistance furnace, keep it at 1200°C for 1h, then heat it at 6°C Cooling at a rate of / min, when the sample temperature drops to 950°C, start pulse current treatment, the specific parameters are: pulse voltage 22V, pulse current 60A, pulse frequency 30Hz, when the sample temperature drops to 750°C, stop pulse current treatment , and the sample was taken out and quenched in an aqueous solution with a NaCl concentration of 10%. Its microstructure is as figure 2 shown.

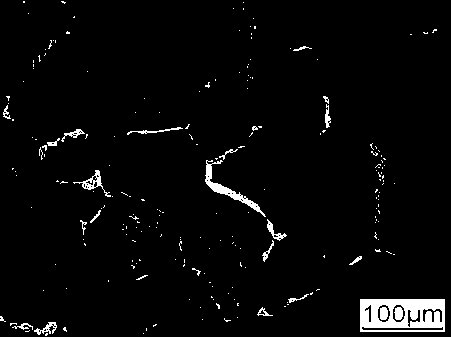

[0028] In order to compare and illustrate the significant effect of the present invention on improving the cracks of low-carbon ...

Embodiment 2

[0031] The material of this example is 16Mn steel (its main chemical composition is: 0.13%C, 0.165%Si, 1.42%Mn, 0.008%P, 0.005%S, 0.045%Al, 0.0045%N), and the section of the slab is 230mm× 2100mm, the pouring temperature is 1542°C, and the casting speed is 1.15m / min. The pulse current device is installed on both sides of the conveying roller table after the slab is cut, and is installed at ten places along the conveying direction of the roller table after the slab is cut, and performs pulse current treatment on the wide surface of the slab. In this embodiment, the pulse voltage is 35V, the pulse current is 95A, and the pulse frequency is 35Hz. When the pulse current treatment started, the actual temperature of the central temperature of the wide face of the slab was 900°C, and the central temperature of the wide face of the slab was 765°C at the end of the treatment. The slab is hot sent by the roller table into the heating furnace and then rolled. The surface of the rolled s...

Embodiment 3

[0033] The basic processing method of this embodiment is the same as that of Embodiment 2, the difference being that the pulse voltage in this embodiment is 25V, the pulse current is 35A, and the pulse frequency is 50Hz. (Red gift) Crackle has a significant effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com