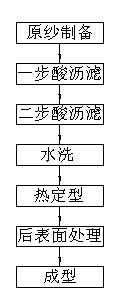

Production process of high-strength high-silicon dioxide glass fiber yarns

A high-silica glass fiber and production process technology, applied to two or more different solvent-based treatment materials, yarns, heating/cooling fabrics, etc., can solve the problem of acid leaching initial speed, product strength reduction, etc. , to achieve the effect of improving the application field, improving the quality stability, and improving the strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) The ternary high-silica glass fiber precursor with a specification of BC8-24 is annealed, and annealed into a BC8-24×4Z110 yarn, and then plied to form a BC8-24×4×3S110 High silica fiberglass raw yarn.

[0022] (2) Wind the raw yarn of BC8-24×4×3S110 on a special yarn frame with a winding machine to make a yarn roll with a length of 2500 meters of raw yarn.

[0023] (3) Distribute the yarn rolls evenly in a suspended manner and place them in the acid leaching tank. There are 40 rolls in total. When the yarn roll is submerged, stop adding acid. After adding acid, start the acid-resistant pump to circulate and stir. After 0.5 hours, stop the pump to stop stirring, and then discharge the acid.

[0024] (4) After the acid is drained, add a hydrochloric acid solution with a concentration of 2.6N to the acid leaching tank. When the acid is immersed in the yarn roll, stop adding acid. , open the steam valve, and heat the acid solution by direct steam heating. When the ac...

Embodiment 2

[0037] (1) The ternary high-silica glass fiber precursor with a specification of BC9-33 is annealed, and annealed into a BC9-33×4Z110 yarn, and then plied to form a BC8-33×4×2S110 High silica fiberglass raw yarn.

[0038] (2) Wind the raw yarn of BC9-33×4×2S110 on a special yarn frame with a winding machine to make a yarn roll with a length of 2400 meters of raw yarn.

[0039] (3) Distribute the yarn rolls evenly in a suspended manner and place them in the acid leaching tank. There are 40 rolls in total. Stop adding acid when the yarn roll is submerged. After adding acid, start the acid-resistant pump to circulate and stir. After 45 minutes, stop the pump, stop stirring, and then discharge the acid.

[0040] (4) After the acid is drained, add a hydrochloric acid solution with a concentration of 2.5N to the acid leaching tank. When the acid is immersed in the yarn roll, stop adding acid. , open the steam valve, and heat the acid solution by direct steam heating. When the acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com