Preparation method for chlorella polypeptide microcapsule

A technology of chlorella peptides and microcapsules, which is applied in peptide preparation methods, food preparation, chemical instruments and methods, etc., can solve the problems of tumor cell drug resistance, low treatment efficiency, and large toxic and side effects, and achieve beneficial The effect of development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of chlorella polypeptide microcapsules, the steps are as follows:

[0030] (1) Chlorella protein was extracted using a low-temperature ultrahigh-pressure continuous flow cell crusher: Mix chlorella powder and pure water at a mass ratio of 1:20 and stir for 50 minutes to obtain a mixed solution. Extract the chlorella protein from the above mixed solution at a temperature of 6°C and a pressure of 100 MPa, and obtain the crude extract as the next extraction solution for re-extraction. The number of extractions is 3 times, and the time for each extraction is 20min. Finally, the obtained solution was centrifuged at a temperature of 4 °C and a speed of 6000 r / min for 30 min to remove the precipitate to obtain a protein supernatant, and then rapidly freeze-dried in a vacuum to obtain a chlorella protein powder.

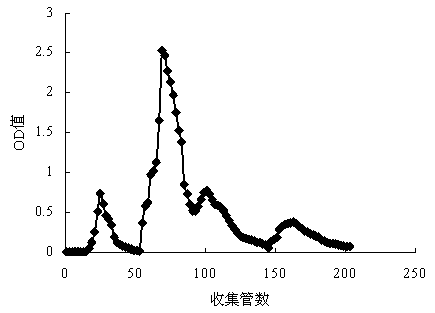

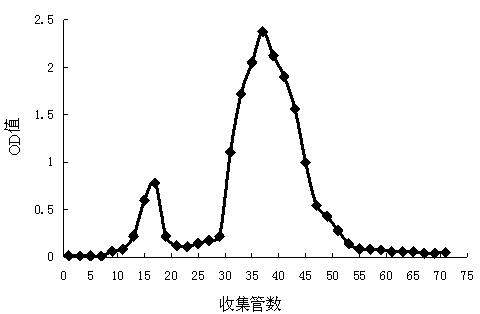

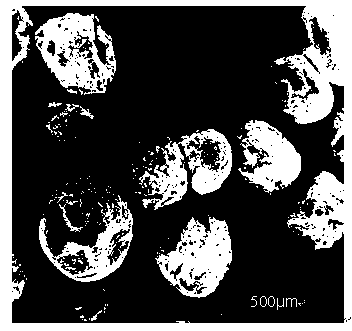

[0031] (2) Based on the chlorella protein powder obtained in step (1), prepare a chlorella protein solution with a concentration of 2%, and ad...

Embodiment 2

[0037] The preparation method of chlorella polypeptide microcapsules, the steps are as follows:

[0038] (1) Chlorella protein was extracted using a low-temperature ultrahigh-pressure continuous flow cell crusher: Mix chlorella powder and pure water at a mass ratio of 1:30 and stir for 80 minutes to obtain a mixed solution. Extract the chlorella protein from the above mixed solution at a temperature of 8°C and a pressure of 150 MPa, and obtain the crude extract as the next extraction solution for re-extraction. The number of extractions is 6 times, and the time for each extraction is 50min. Finally, the obtained solution was centrifuged at a temperature of 4 °C and a speed of 5000 r / min for 20 min to remove the precipitate to obtain a protein supernatant, and then rapidly freeze-dried in a vacuum to obtain a chlorella protein powder.

[0039] (2) Based on the chlorella protein powder obtained in step (1), configure a chlorella protein solution with a concentration of 2%, and ...

Embodiment 3

[0043] The preparation method of chlorella polypeptide microcapsules, the steps are as follows:

[0044] (1) Chlorella protein was extracted using a low-temperature ultra-high pressure continuous flow cell disruptor: Mix chlorella powder and pure water at a mass ratio of 1:35 and stir for 100 minutes to obtain a mixed solution. Extract the chlorella protein from the above mixed solution at a temperature of 9°C and a pressure of 200 MPa, and obtain the crude extract as the next extraction solution for re-extraction. The number of extractions is 2 times, and the time for each extraction is 10min. Finally, the obtained solution was centrifuged at 4 °C and 8000 r / min for 30 min to remove the precipitate to obtain the protein supernatant, and then quickly freeze-dried in vacuum to obtain the chlorella protein powder.

[0045] (2) Based on the chlorella protein powder obtained in step (1), prepare a chlorella protein solution with a concentration of 2%, and add papain for hydrolysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com