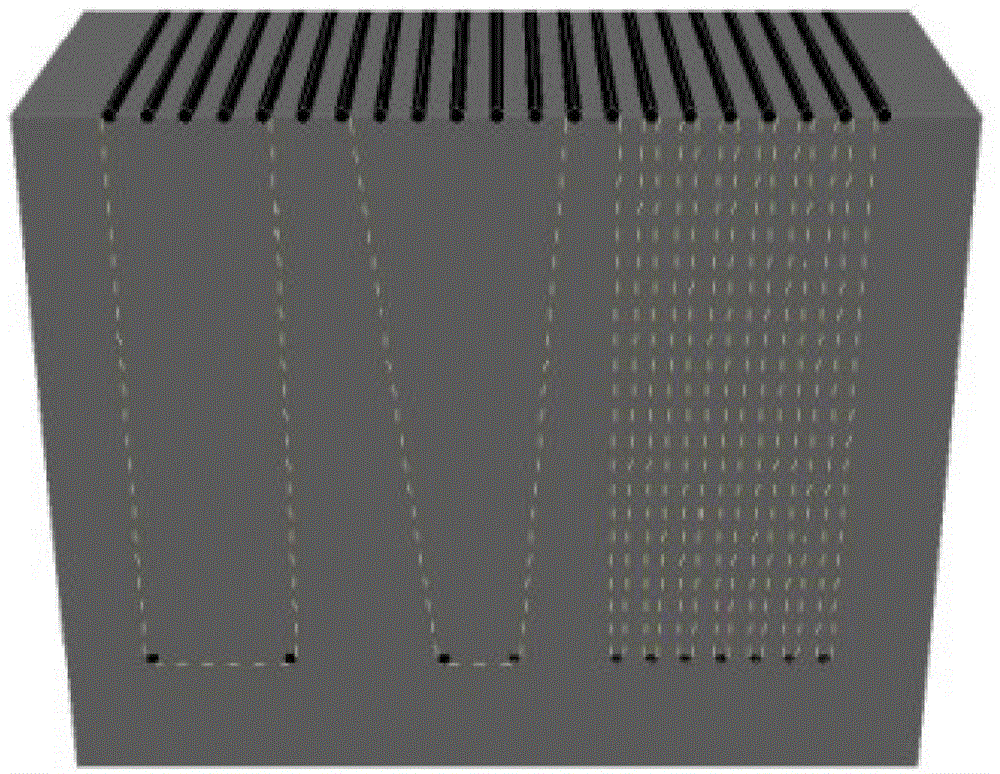

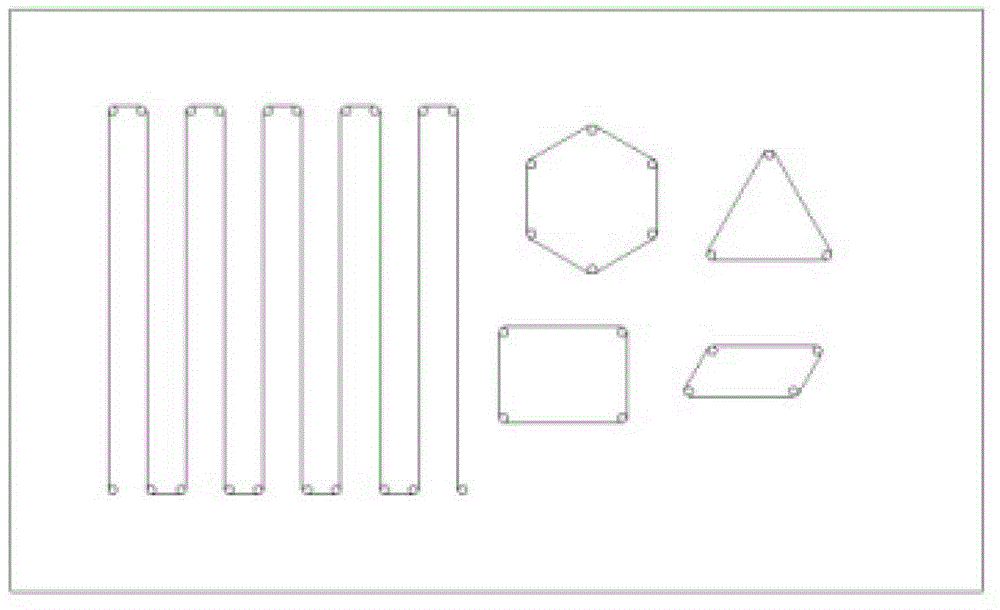

Method for producing light transmitting concrete with light transmitting mode design

A light-transmitting concrete and optical fiber technology, which is applied in manufacturing tools, ceramic molding machines, etc., can solve the problems that it is difficult to give full play to the light-transmitting ability of optical fibers, the high manufacturing cost of light-transmitting cement-based materials, and the difficulty in preparing 3D or 2D fabrics. , to achieve the full play of light transmission performance, simple and achievable operation, and the effect of improving light transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

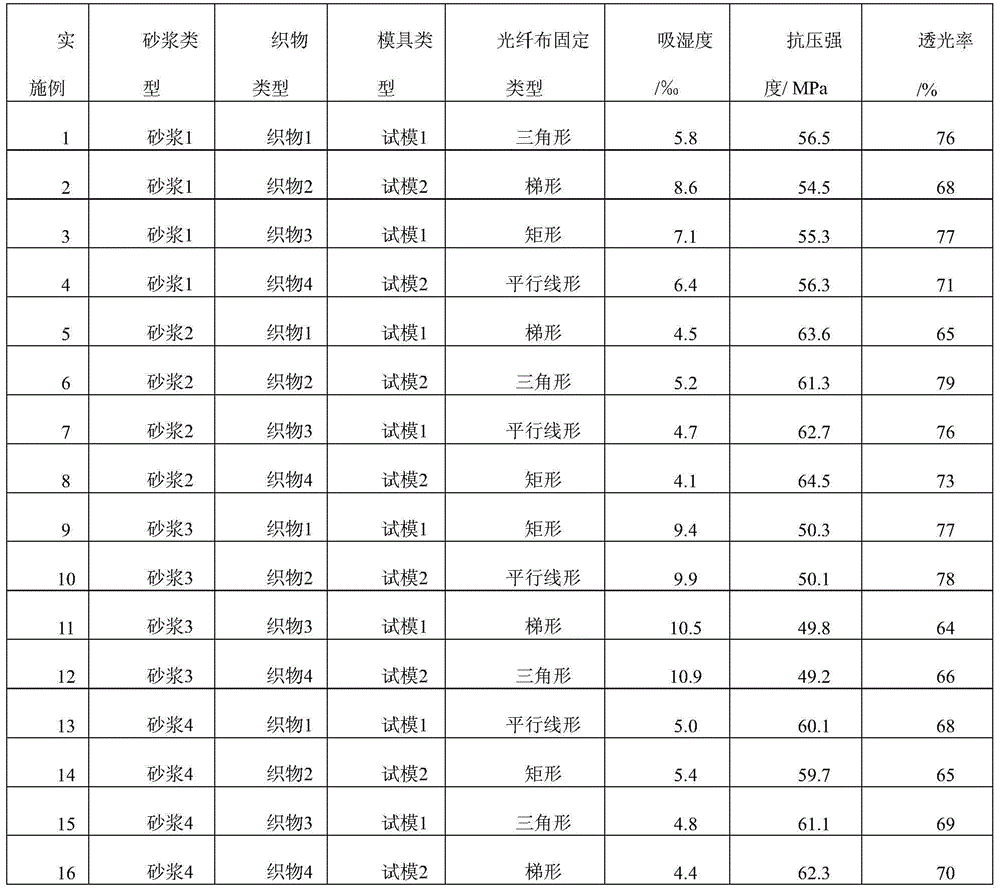

[0030] The raw material composition of mortar in the implementation example is as follows respectively:

[0031] Mortar 1: The cementitious material is P.O32.5 Portland cement with a weight ratio of 75% compounded with 25% S95 grade mineral powder produced by Beijing Changping Jinyulai Mineral Powder Factory, and the water-cement ratio is 0.35; the particle size of quartz sand The diameter range is 0.06-1.18mm, and the mass ratio of quartz sand to cementitious material is 0.75; the dosage of P764 powder defoamer produced by Shenzhen Hairun Chemical Co., Ltd. is 0.35% of the total mass of the material. The fluidity of the cement mortar is adjusted by adding Suzhou FOX-8H powder polycarboxylate water reducer with a water reducing rate greater than 15%, so that the consistency reaches 16cm; the 28-day compressive strength of the mortar reaches 58MPa.

[0032] Mortar 2: The cementitious materials include cement and mineral powder. The cement is P.O32.5 Portland cement. The mineral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com