Laboratory method for preparing hydrocarbons by deoxidizing stearic acid

A technology of hydrocarbons and stearic acid, applied in the field of biofuel production and preparation, can solve the problems of unsuitable use of vegetable oil, high condensation point, and difficult storage, etc., to reduce greenhouse gas emissions, strong low-temperature fluidity, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

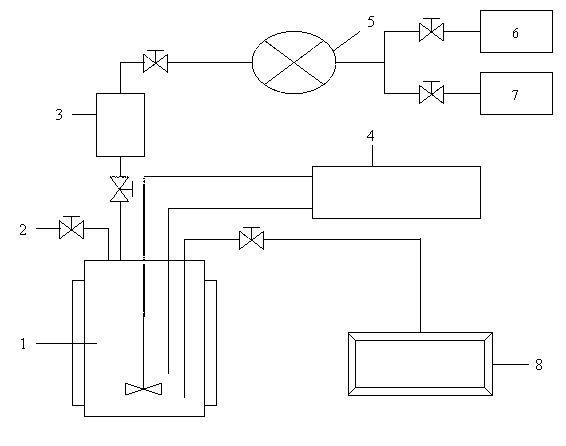

Image

Examples

Embodiment 1

[0021] (1) Weigh an appropriate amount of 5 wt.% Pd / C catalyst and add it to the reaction kettle, seal the reaction kettle, exhaust the air in the kettle with argon, and fill the hydrogen with a volume fraction of 25% to a pressure of 0.50-0.80MPa , the temperature was raised to 200°C at a rate of 5°C / min and kept for 30 minutes, and then allowed to stand at room temperature for later use.

[0022] (2) Add 2.0g of pretreated Pd / C catalyst, 90.0g of stearic acid and 80.0g of dodecane into the reaction kettle, seal the reaction kettle, exhaust the air in the kettle with argon, and fill it with 25% hydrogen The raw material gas mixed with 75% argon is stirred and heated to a temperature of 300±5°C under the conditions of a pressure of 2.0MPa and a rotation speed of 200rpm. After a reaction of 6 hours, it is cooled to room temperature. The reaction product in the kettle is taken out, and the Pd / C catalyst is separated by filtration. Drying yields a petroleum-like based hydrocarbon...

Embodiment 2

[0026] (1) Weigh an appropriate amount of 5wt.% Pd / C catalyst and add it to the reaction kettle, seal the reaction kettle, exhaust the air in the kettle with argon, and fill the hydrogen with a volume fraction of 25% to a pressure of 0.50-0.80MPa, Raise the temperature to 200°C at a rate of 5°C / min and keep it for 30 minutes, then let it stand at room temperature for later use.

[0027] (2) Add 3.0g of pretreated Pd / C catalyst, 90.0g of stearic acid and 80.0g of dodecane into the reaction kettle, seal the reaction kettle, exhaust the air in the kettle with argon, and fill it with 25% hydrogen The raw material gas mixed with 75% argon is stirred and heated to a temperature of 300±5°C under the conditions of a pressure of 2.0MPa and a rotation speed of 200rpm. After a reaction of 6 hours, it is cooled to room temperature. The reaction product in the kettle is taken out, and the Pd / C catalyst is separated by filtration. Drying yields a petroleum-like based hydrocarbon liquid. Ac...

Embodiment 3

[0031] (1) Weigh an appropriate amount of 5wt.% Pd / C catalyst and add it to the reaction kettle, seal the reaction kettle, exhaust the air in the kettle with argon, and fill the hydrogen with a volume fraction of 25% to a pressure of 0.50-0.80MPa, Raise the temperature to 200°C at a rate of 5°C / min and keep it for 30 minutes, then let it stand at room temperature for later use.

[0032](2) Add 3.5g of pretreated Pd / C catalyst, 90.0g of stearic acid and 80.0g of dodecane into the reaction kettle, seal the reaction kettle, exhaust the air in the kettle with argon, and fill it with 25% hydrogen The raw material gas mixed with 75% argon is stirred and heated to a temperature of 300±5°C under the conditions of a pressure of 2.0Mpa and a rotation speed of 200rpm. After a reaction of 6 hours, it is cooled to room temperature. The reaction product in the kettle is taken out, and the Pd / C catalyst is separated by filtration. Drying yields a petroleum-like based hydrocarbon liquid. Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com