Parallel type polymer solar cell and preparation method thereof

A technology of solar cells and polymers, applied in the field of solar cells, can solve the problems of restricted efficiency, limited sunlight absorption, low photoelectric conversion efficiency, etc., and achieve the effect of improving injection efficiency and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

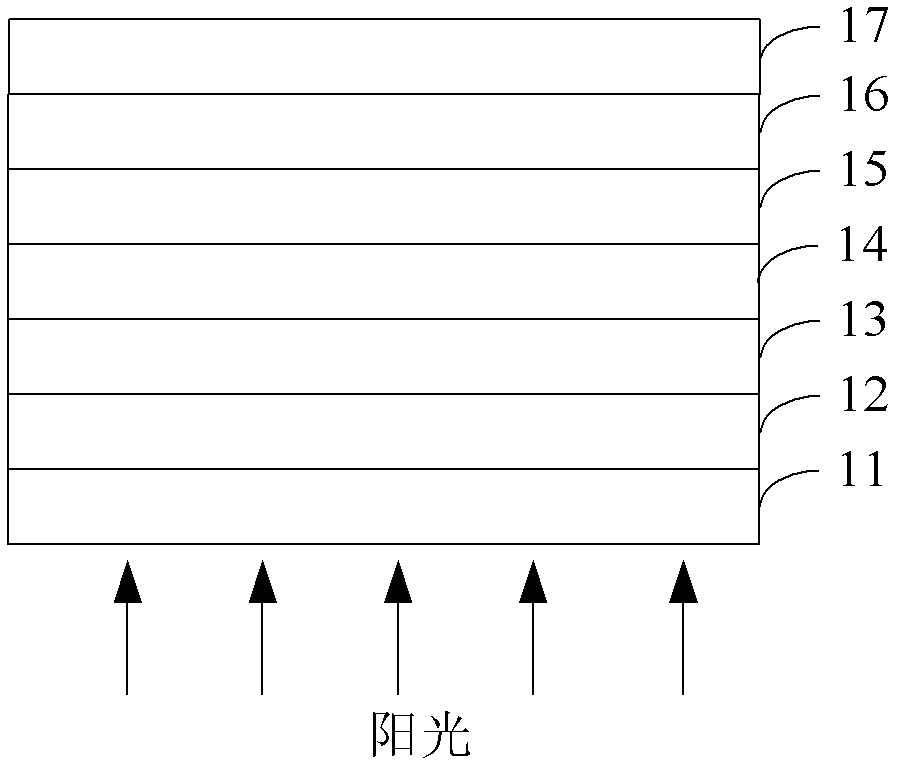

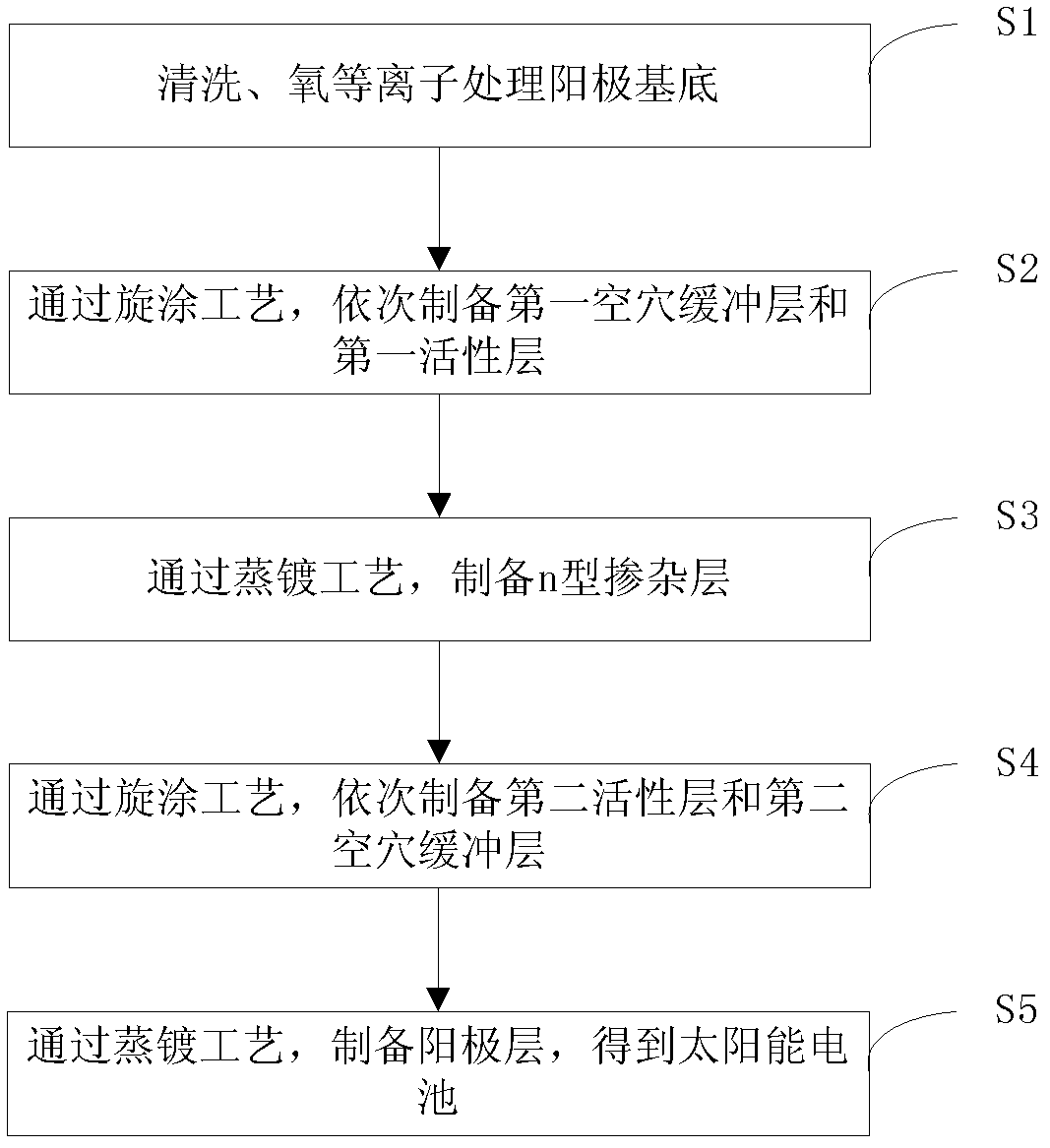

[0040] The preparation method of above-mentioned parallel type polymer solar cell, such as figure 2 As shown, the process steps are as follows:

[0041] S1. Ultrasonic cleaning the anode base in detergent, deionized water, acetone, ethanol, and isopropanol in order to remove organic pollutants on the surface; after cleaning, perform oxygen plasma treatment at a power of 10-50W for 5 ~15min, or UV-ozone treatment 5~20min;

[0042] S2. Spin-coat a first hole buffer layer with a thickness of 20-80 nm on the surface of the anode layer of the anode substrate, and then spin-coat a first active layer with a thickness of 80-300 nm on the surface of the first hole buffer layer after drying, and then dry deal with;

[0043] S3. Evaporating an n-type doped layer with a thickness of 10-150 nm on the surface of the first active layer;

[0044] S4, coating a second active layer with a thickness of 80-300 nm on the surface of the n-type doped layer, and then drying; then spin-coating a s...

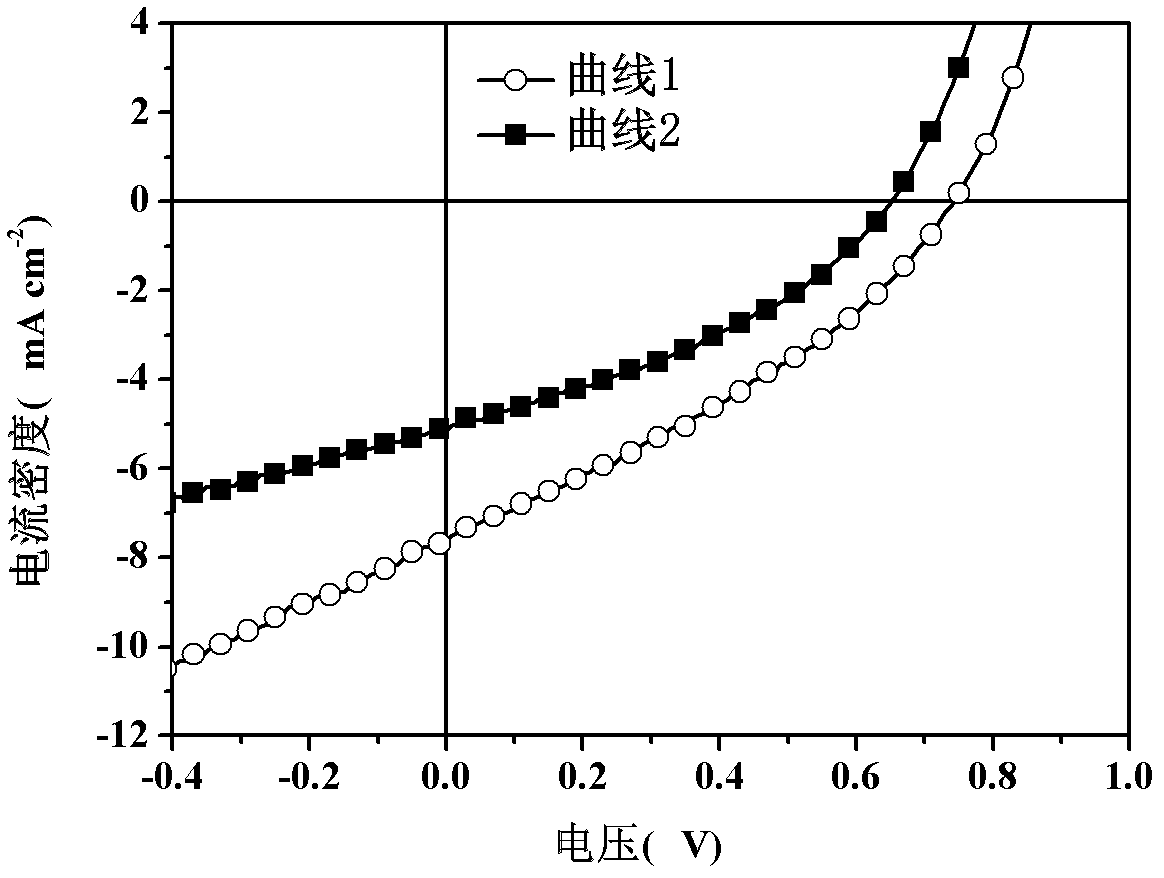

Embodiment 1

[0051] The structure of the parallel polymer solar cell in this embodiment is: ITO substrate / PEDOT:PSS / P3HT:PCBM / CsN 3 :Bphen / P3HT:PCBM / PEDOT:PSS / Al.

[0052] The preparation process of the parallel polymer solar cell is as follows:

[0053] 1. Clean the ITO substrate (where ITO is the anode layer) with detergent, deionized water, acetone, ethanol, and isopropanol in sequence, and ultrasonically clean for 15 minutes each to remove organic pollutants on the glass surface. After cleaning, The ITO layer of the ITO substrate was treated with oxygen plasma for 15 minutes at a power of 10W;

[0054] 2. Prepare PEDOT:PSS aqueous solution (wherein, PEDOT:PSS mass ratio is 6:1; The total mass percentage of PEDOT and PSS is 1.5wt%) is prepared on the ITO layer surface of ITO substrate by the mode of spin coating; Drying, Prepare a first hole buffer layer with a thickness of 40nm;

[0055] 3. Spin-coat the P3HT:PCBM chlorobenzene solution system on the surface of the first hole buffer...

Embodiment 2

[0068] The structure of the parallel polymer solar cell in this embodiment is: IZO substrate / PEDOT:PSS / P3HT:PCBM / CsF:PBD / MDMO-PPV:PCBM / PEDOT:PSS / Ag.

[0069] The preparation process of the parallel polymer solar cell is as follows:

[0070] 1. Clean the IZO substrate (where IZO is the anode layer) with detergent, deionized water, acetone, ethanol, and isopropanol in sequence, and ultrasonically clean for 15 minutes each to remove organic pollutants on the glass surface. After cleaning, Treat the IZO surface of the IZO substrate with oxygen plasma for 10 minutes at a power of 30W;

[0071] 2. Prepare the PEDOT:PSS aqueous solution on the IZO surface of the IZO substrate by spin coating; dry and dry to obtain the first hole buffer layer with a thickness of 20nm;

[0072] 3. Spin-coat the P3HT:PCBM toluene solution system on the surface of the first hole buffer layer. After the spin coating, anneal at 200°C for 80 minutes to obtain the first active layer with a thickness of 300n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com