Allylthiourea modified konjac glucomannan copolymer material and slow-release nitrogen fertilizer

A technology of konjac glucomannan and allyl thiourea is applied in the direction of fertilizer form, fertilization device, fertilizer mixture, etc., to achieve the effect of promoting maximum utilization rate, enhancing air permeability and strong renewability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the preparation method of allyl thiourea modified KGM copolymer slow-release material:

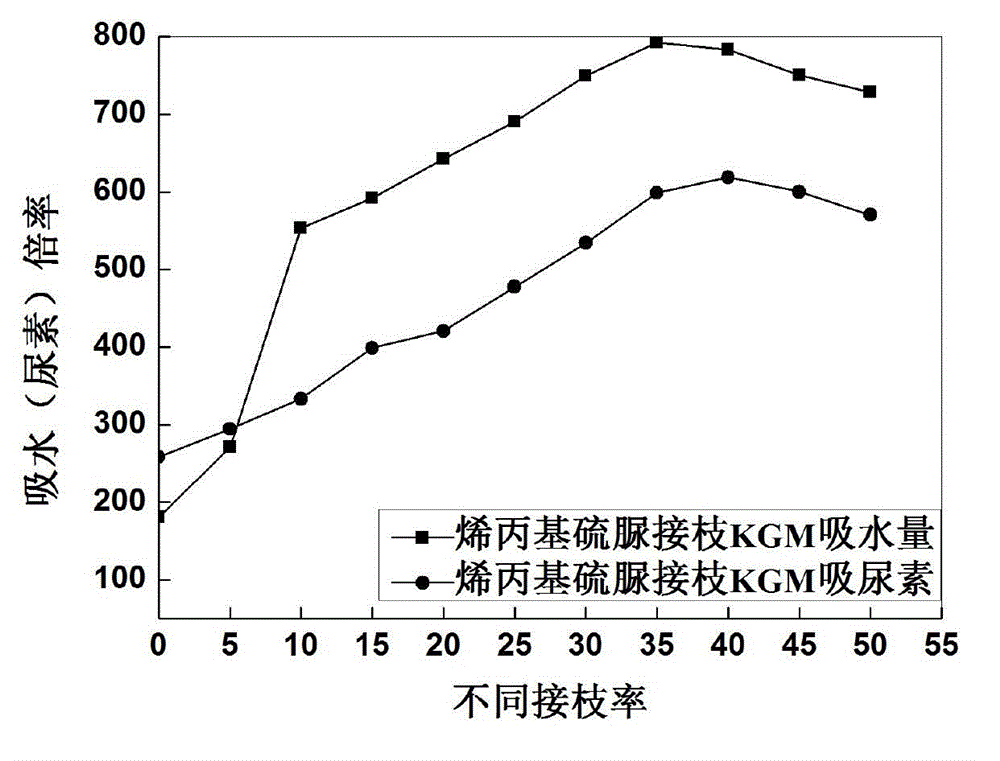

[0030] With KGM as the basic composition, in N 2 Under protection, fully swell in 80% ethanol, slowly add initiator Fe 2+ / H 2 o 2 , through N 2 After 15 minutes, add monomer allylthiourea, after 1.5 hours of reaction, slowly heat up to 80°C, add 10% NaOH solution under constant stirring, adjust pH to neutral, wash with acetone and 90% ethanol respectively, filter, After drying, it becomes allylthiourea modified KGM copolymer slow-release material. During synthesis, the grafting rate is controlled to be 10-50%, more preferably 35-40%.

[0031] The konjac glucomannan used in the allylthiourea modified KGM copolymer slow-release material process is industrial grade, with a molecular weight of 5.0×10 5 ~1.0×10 6 , Polymerization degree 500~600; Allyl thiourea, molecular weight 116, chemically pure, content ≥ 99.5%; Structural formula:

[0032] The allylthiourea ...

Embodiment 2

[0037] (1) Pour 100g of urea into a container with a mechanical stirrer, raise the temperature of the stirrer to 80-90°C to make the urea into a molten state, slowly add 1.5g of a copolymer slow-release material with a graft rate of 39%, and continue After stirring for 10-15 minutes, blend and granulate;

[0038] (2) While keeping the temperature inside the coating machine at 60-65°C, spray 0.8g of coating material so that the coating agent is evenly wrapped on the surface of the fertilizer, and the control time is 10-20min; then spray the copolymer for slow release Material;

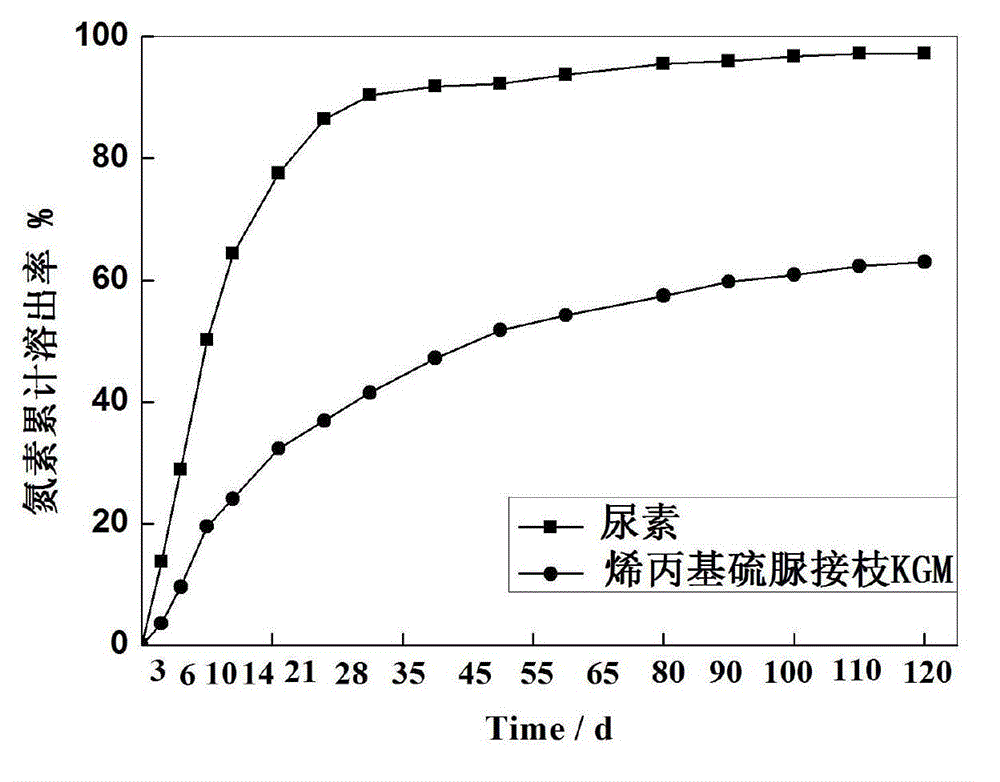

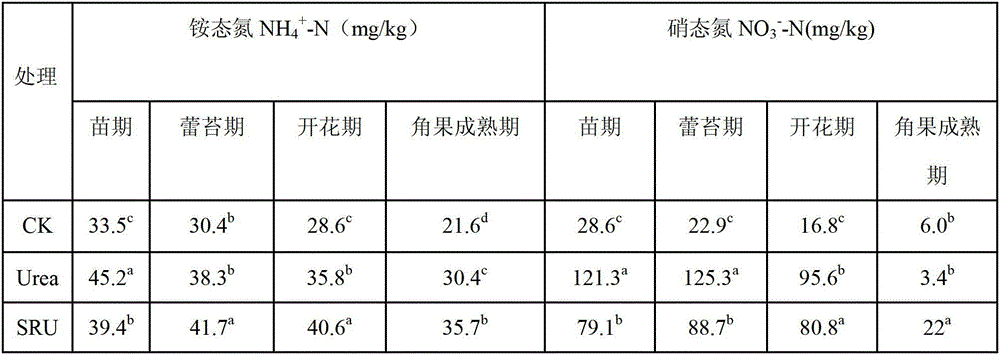

[0039] (3) Cool and solidify to produce a new type of slow-release nitrogen fertilizer with high water retention and fertilizer retention, which can inhibit soil nitrification. The modified KGM material slow-release fertilizer can be in the shape of flakes, granules or cylinders.

Embodiment 3

[0040] Embodiment 3: The preparation method is as described in Embodiment 2, the difference is that the components are as follows, all in parts by mass:

[0041] A slow-release fertilizer containing an allylthiourea-modified KGM copolymer coating material. In the slow-release fertilizer, in parts by mass: 100 parts by mass, 0.1-10 copolymer slow-release materials, and 0.1-10 coating agents 8.

[0042] The coating agent is one or more of sugarcane peel, orange peel, pomelo peel, peanut shell, bran, bran powder, which is processed into a particle size of 200 mesh after screening, drying, crushing and sieving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com