Preparation method of EPDM (Ethylene-Propylene-Diene Monomer) rubber

A technology of EPDM rubber and ethylene, which is applied in the field of rubber materials, can solve the problems of less types of third monomers and unfavorable development of EPDM rubber, and achieve good processing performance, appropriate double bond content, and high conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention discloses a preparation method of EPDM rubber, comprising the following steps:

[0026] In an organic solvent, ethylene, propylene and a third monomer are polymerized under the action of a catalyst system to obtain EPDM rubber;

[0027] The third monomer is a polybutadiene rubber with a 1,2-polybutadiene content of more than 9% or a polyisoprene rubber with a 3,4-polyisoprene content of more than 9%, and the The weight average molecular weight of the third monomer is 200,000 to 1 million;

[0028] The catalyst system includes a vanadium-based catalyst, an aluminum alkyl compound and an activation accelerator;

[0029] The vanadium series catalyst is VOCl 3 , VO (P 204 ) 2 , V (acac) 3 、VOCl 3 nMOH, VO 2 Cl (trioctylamine), VO 2 Cl 3 3 (tributyl phosphate), VO(OH) (octahydroxyquinoline) 2 or VO(OH)·(α-benzoin oxime) 2 , M is an alkyl group of C5~C8, 2.5≤n≤3.5;

[0030] Alkyl aluminum compound is AlR 3 , AlR 2 X, Al 2...

Embodiment 1

[0040] In a 0.5L reactor fully replaced with nitrogen, add (1) 300ml hexane, (2) 0.10mmol VOCl 3 , (3) 3.0mmol trichlorotriethyldialuminum, molecular formula: Al 2 (C 2 h 5 ) 3 Cl 3 , (4) 100ml of hexane solution containing 0.15g polybutadiene rubber, the weight average molecular weight of the polybutadiene rubber is 2.0×10 5 , with a 1,2-polybutadiene content of 16% and (5) 0.60 mmol of ethyl trichloroacetate (ETCA);

[0041] Then, feed the mixed gas of ethylene and propylene into the reactor, the molar ratio of ethylene and propylene in the mixed gas is 1:2, the pressure reaches 0.4MPa, stir, and react at 20°C for 15min.

[0042] After the polymerization, 5ml of 5% by mass hydrochloric acid-ethanol solution was added to the polymerization product, washed with ethanol, and then dried under vacuum to obtain 12.2g of EPDM rubber.

[0043] According to differential calorimetry (DSC) analysis, the glass transition temperature of the obtained EPDM rubber is -56.6°C; 13 C NM...

Embodiment 2

[0045] In a 0.5L reactor fully replaced with nitrogen, add (1) 300ml hexane, (2) 0.10mmol VOCl 3 , (3) 3.0mmol trichlorotriethyldialuminum, molecular formula: Al 2 (C 2 h 5 ) 3 Cl 3 , (4) hexane solution containing 0.3g polybutadiene rubber, the weight average molecular weight of the polybutadiene rubber is 2.0×10 5 , with a 1,2-polybutadiene content of 21% and (5) 0.60 mmol of ethyl trichloroacetate (ETCA);

[0046] Then, feed the mixed gas of ethylene and propylene into the reactor, the molar ratio of ethylene and propylene in the mixed gas is 1:2, the pressure reaches 0.4MPa, stir, and react at 20°C for 15min.

[0047] After the polymerization, 5 ml of 5% by mass hydrochloric acid-ethanol solution was added to the polymerization product, washed with ethanol, and then dried under vacuum to obtain 13.3 g of EPDM rubber.

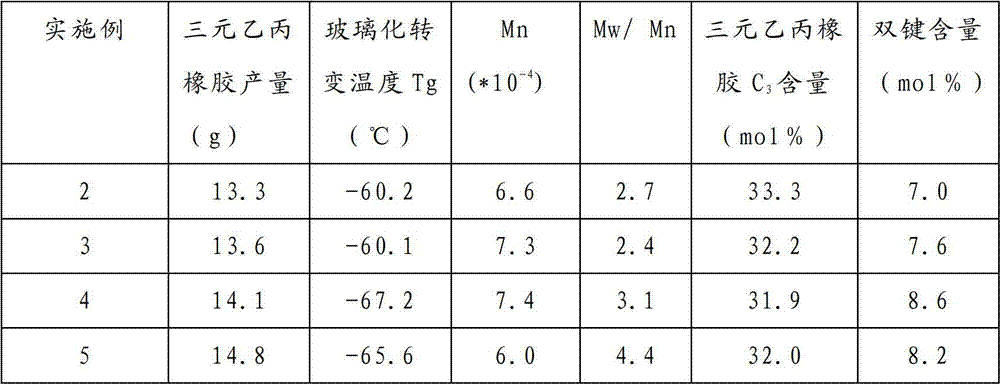

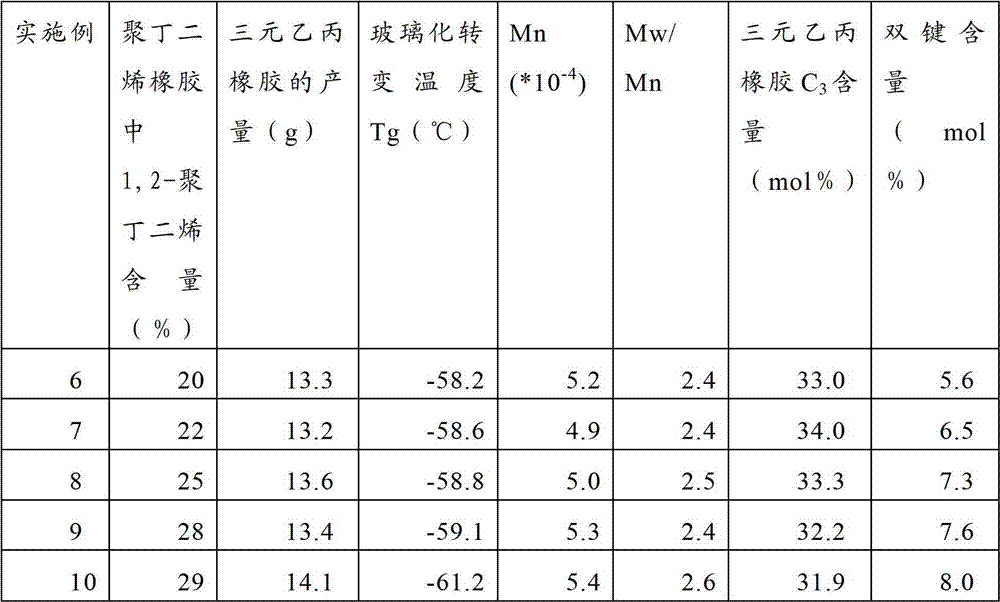

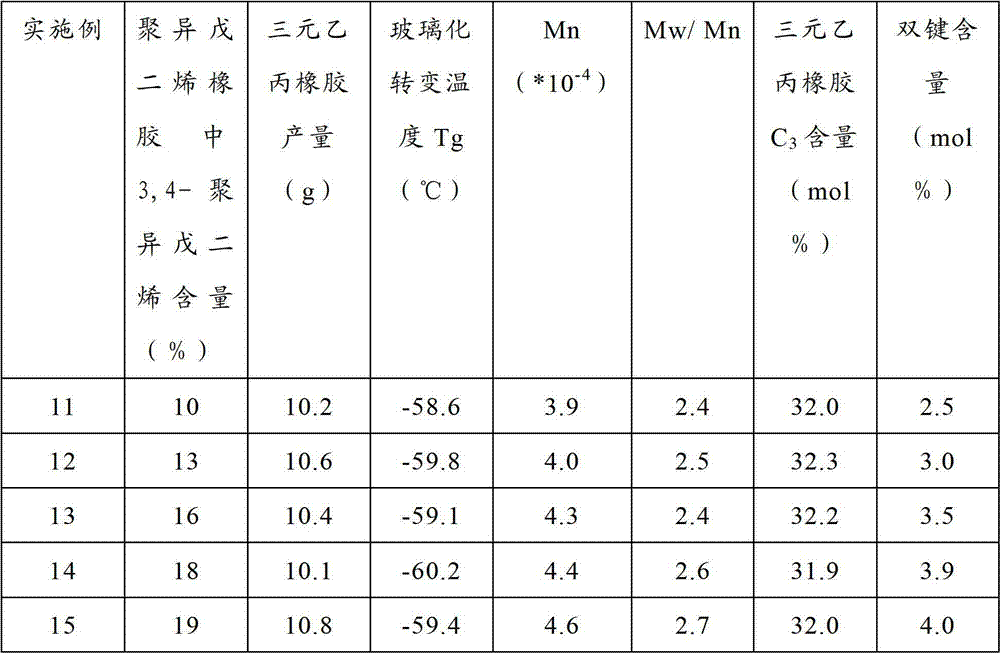

[0048] The performance of the obtained EPDM rubber is tested, and the results are shown in Table 1, and Table 1 is the performance parameters of the E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com