Method for increasing extraction efficiency of copper in water solution

A technology for extracting efficiency and aqueous solution, which is applied in the field of improving the extraction efficiency of copper in aqueous solution, which can solve the problems of high investment, consumption of reagents, and increased liquid volume in the extraction system, and achieves high extraction efficiency and reduced equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The components and properties of the copper-containing solution in the hydrochloric acid system are as follows: 34.38g / L Cu, 1.26g / L Co, 79.30g / L Zn, 8.50 g / L Cd, 237.8g / L sodium citrate, pH=2.45 .

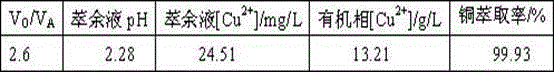

[0023] According to the effective loading rate of 30% LIX622N-kerosene extracting copper is 75% of the theoretical amount, compared to: in this example [Cu]a =34.38g / l, the maximum loading copper amount Lm of the LIX622N-kerosene organic phase with a concentration of 10% =5.9g / l, the volume percentage M=30 of the extractant in the organic phase, then use 30% of the LIX622N-kerosene organic phase to completely extract the copper in the aqueous solution compared to R={10×[Cu]a} / {Lm×M×0.75}={10×34.38} / {5.9×30×0.75}=2.59, therefore, the actual comparison is 2.6. Put 30% LIX622-kerosene organic phase and copper-containing solution into the separatory funnel according to the calculated ratio of 2.6, shake at room temperature for 5 minutes and let it stand still. After the organ...

Embodiment 2

[0027] The components and properties of the copper-containing solution in the sulfuric acid system are as follows: 22.72g / L Cu, 0.83g / L Co, 75.05g / L Zn, 2.50 g / L Cd, 142.67g / L ammonium citrate added, pH=1.55 .

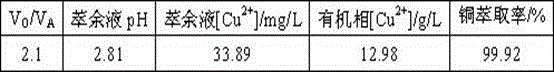

[0028] For the copper-containing solution, when using 30% LIX984N-kerosene organic phase extraction, calculated according to the maximum load of the organic phase, the theoretical ratio is 1.3 when all the copper is to be extracted. Take 30mL of copper-containing solution each time, at room temperature, mix and shake 30% LIX984N3-kerosene organic phase and water phase according to different phases for 5 minutes, the oscillation frequency is 320r / min, after standing still, separate the water phase and organic phase, and detect the extraction The pH value of the remaining liquid, the experimental results are shown in Table 2, where O / A is the volume ratio of the organic phase to the aqueous phase.

[0029] Table 2

[0030] Test No. O / A Raffinate contains C...

Embodiment 3

[0032] The components and properties of the copper-containing nitric acid solution are as follows: 26.51g / L Cu, 0.78g / L Co, 47.59g / L Zn, 4.72 g / L Cd, 165.44g / L calcium citrate, pH=4.50 .

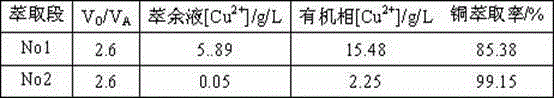

[0033] According to the effective load rate of 30% LIX973N-kerosene extracting copper is calculated as 75% of the theoretical amount, add 30% LIX973N-kerosene extractant and copper-containing leachate to the separatory funnel according to the calculated ratio, and shake at room temperature for 5 minutes After standing still, after the organic phase and the water phase are completely separated, the water phase is released, the copper content in the water phase is analyzed, and the extraction rate of copper is calculated. The results are shown in Table 3:

[0034] table 3

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com