Inoculated cast iron and preparation method thereof

A technology of inoculated cast iron and ingot, applied in the field of inoculated cast iron and its preparation, can solve the problems of lack of market competitiveness, high material cost, complicated preparation, etc., achieve low production cost, improve comprehensive mechanical properties, and improve carbide form Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

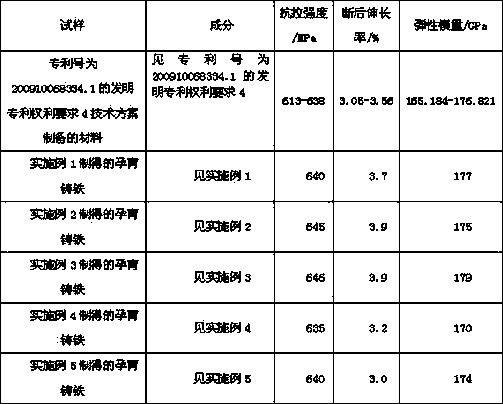

Examples

Embodiment 1

[0026] (1) Weigh each raw material according to the composition of inoculated cast iron, the purity of chromium is greater than 99.5%; Si is added in the form of 75 ferrosilicon master alloy; Mn is added in the form of 65 ferromanganese master alloy; iron is added in the form of 20 steel; C is added in the form of graphite containing 99.9% carbon; Nd, Sn, Se and Ti are added in the form of Nd-Sn-Se-Ti-Zn iron alloy powder, and the particle diameter of the Nd-Sn-Se-Ti-Zn iron alloy powder is 1-3 mm, the composition and content are Nd 5%, Sn 5%, Se 5%, Ti 5%, Zn 5%, and the rest is iron; all percentages are percentages by weight. P and S in inoculated cast iron are brought in by 20 steel, 75 ferrosilicon master alloy and 65 ferromanganese master alloy.

[0027] Although Zn is contained in Nd-Sn-Ti-Se-Zn iron alloy powder, Zn volatilizes at high temperature.

[0028] (2) First add 75 ferrosilicon master alloy, 65 ferromanganese master alloy, 20 steel, chromium and graphite into ...

Embodiment 2

[0034] (1) Weigh each raw material according to the composition of inoculated cast iron, the purity of chromium is greater than 99.5%; Si is added in the form of 75 ferrosilicon master alloy; Mn is added in the form of 65 ferromanganese master alloy; iron is added in the form of 20 steel; C is added in the form of graphite containing 99.9% carbon; Nd, Sn, Se and Ti are added in the form of Nd-Sn-Se-Ti-Zn iron alloy powder, and the particle diameter of the Nd-Sn-Se-Ti-Zn iron alloy powder is 1-3 mm, the composition and content are Nd 5%, Sn 5%, Se 5%, Ti 5%, Zn 5%, and the rest is iron; all percentages are percentages by weight. P and S in inoculated cast iron are brought in by 20 steel, 75 ferrosilicon master alloy and 65 ferromanganese master alloy. Although the Nd-Sn-Ti-Se-Zn iron alloy powder contains Zn, Zn will volatilize at high temperature.

[0035] (2) First add 75 ferrosilicon master alloy, 65 ferromanganese master alloy, 20 steel, chromium and graphite into the indu...

Embodiment 3

[0041] (2) First add 75 ferrosilicon master alloy, 65 ferromanganese master alloy, 20 steel, chromium and graphite into the induction furnace to melt to form alloy liquid, and the melting temperature is 1520°C;

[0042] (3) Put the Nd-Sn-Se-Ti-Zn iron alloy powder into the pit in the embankment ladle, then cover it with plant ash, pour the alloy liquid into the ladle, and after 10 minutes, pour the liquid in the ladle Pouring into a steel metal mold to form an ingot, the shape of the ingot is a cylinder with a diameter of 100-200mm and a height of 200-400mm; the pouring temperature is 1500°C.

[0043] (4) Heating the ingot to 990° C. and holding it for 5 hours, air quenching, and tempering to obtain inoculated cast iron. The tempering temperature is 240°C.

[0044] Example 4

[0045] Inoculated cast iron, the weight percentage of each component is as follows: C 3.0%, Si 1.2%, Mn 1.2%, P 0.03%, S 0.06%, Cr 20%, Nd 0.20%, Sn 0.20%, Ti 0.20%, Se 0.20% and the rest is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com