Preparation method of through-hole anodic aluminum oxide template

An anodic oxidation of aluminum and anodic oxidation technology, applied in the field of electrochemistry, can solve the problems of complex removal process of barrier layer, difficult operation, and difficult control of opening size, so as to avoid corrosion process of barrier layer removal, avoid pollution and environment Contamination, the effect of improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

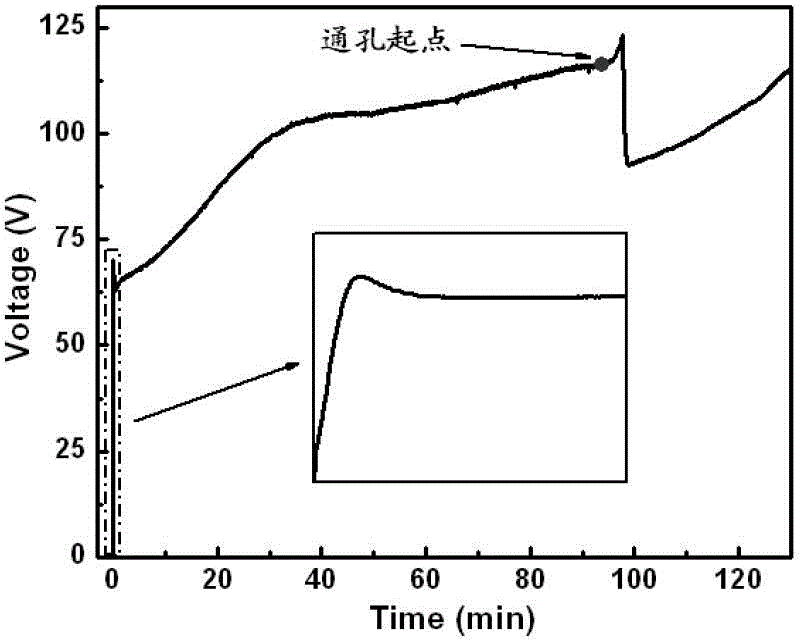

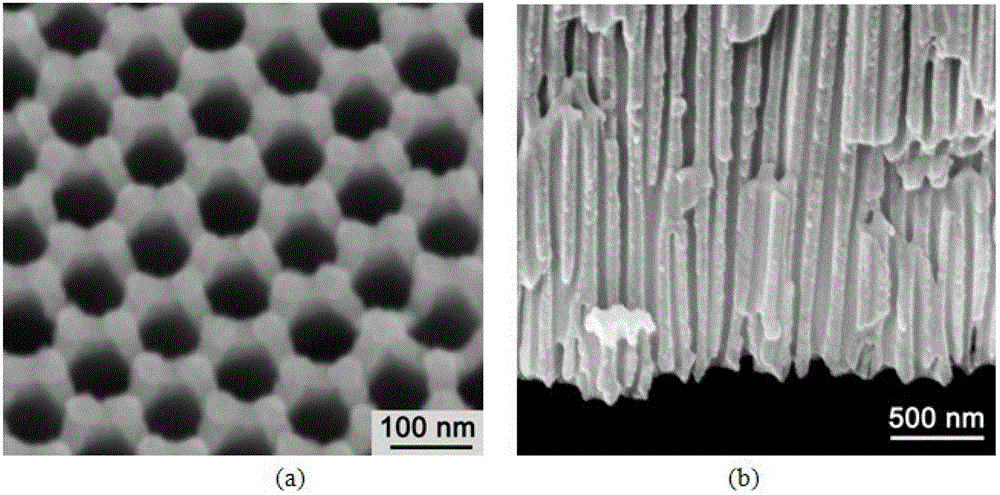

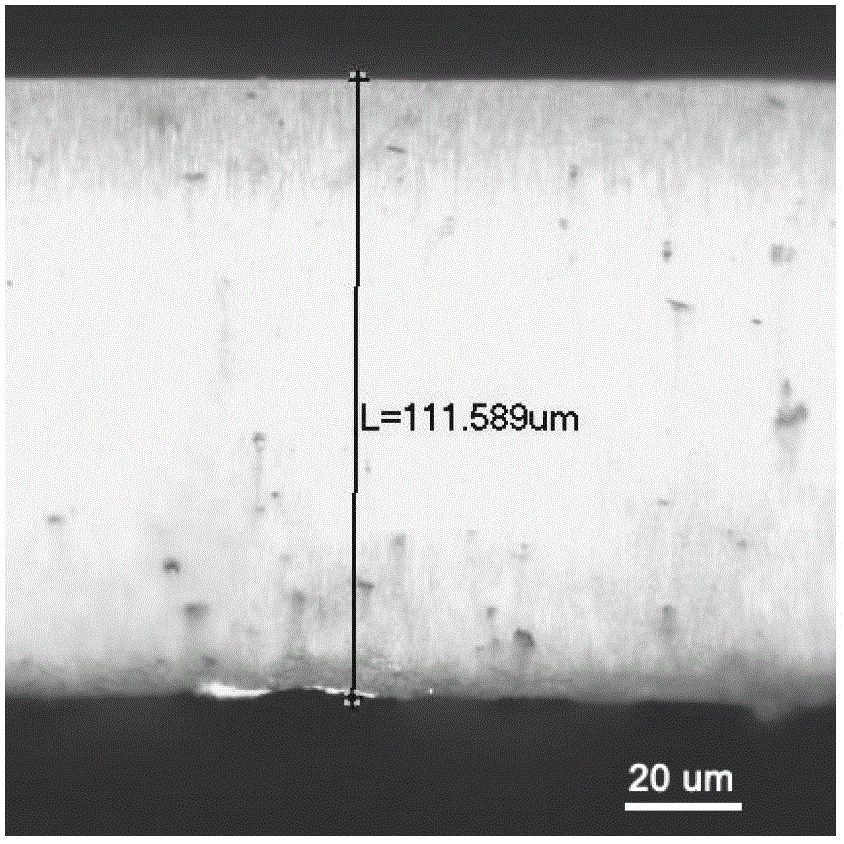

[0034]First, take two strips of aluminum foil with a purity of 99.99%, a length of 70 mm, a width of 20 mm, and a thickness of 150 μm, and put 2 wt%, 70 ° C in NaOH solution for 2 min to remove the natural oxide film on the surface of the aluminum foil. Two pieces of aluminum foil were overlapped and fixed in the mold, and then the mold was put into a hydraulic press, pressurized at 10 MPa, and maintained for 30 min. Then take out the double-layer composite aluminum foil that has been bonded, rinse it repeatedly with deionized water, and use it as the anode for anodic oxidation, and then use the platinum mesh as the cathode. With 0.75 M oxalic acid solution as the electrolyte, at 50 mA cm -2 The current density (high field anodization) at a constant temperature of 20 ° Under C, single-sided constant current anodizing is carried out. The oxidation time is determined by measuring the change of voltage in real time. When the voltage rises rapidly, the current is halved, and it...

Embodiment 2

[0036] First, take two strips of aluminum foil with a purity of 99.99%, a length of 70 mm, a width of 20 mm, and a thickness of 150 μm, and put 2 wt%, 70 ° C in NaOH solution for 2 min to remove the natural oxide film on the surface of the aluminum foil. Two pieces of aluminum foil were overlapped and fixed in the mold, then the mold was put into the hydraulic press, pressurized at 5 MPa, and maintained for 60 min. Then take out the double-layer composite aluminum foil that has been bonded, rinse it repeatedly with deionized water, and use it as the anode for anodic oxidation, and then use the platinum mesh as the cathode. With 0.75 M oxalic acid solution as the electrolyte, at 50 mA cm -2 The current density at a constant temperature of 20 ° Under C, single-sided constant current anodizing is carried out. The oxidation time was determined by measuring the change of the voltage in real time. When the voltage rose rapidly, the current was halved and kept for 30 min before st...

Embodiment 3

[0038] Firstly, take a strip of aluminum foil with a purity of 99.99%, a length of 70 mm, a width of 20 mm, and a thickness of 150 μm and 100 μm, respectively, and put 2 wt%, 70 ° C in NaOH solution for 2 min to remove the natural oxide film on the surface of the aluminum foil. Two pieces of aluminum foil were overlapped and fixed in the mold, and then the mold was put into a hydraulic press, pressurized at 10 MPa, and maintained for 30 min. Then take out the bonded double-layer composite aluminum foil, rinse it repeatedly with deionized water, use the side of the aluminum foil with a thickness of 100 μm as the anode for anodic oxidation, and then use the platinum mesh as the cathode. With 0.75 M oxalic acid solution as the electrolyte, at 50 mA cm -2 The current density at a constant temperature of 20 ° Under C, single-sided constant current anodizing is carried out. The oxidation time was determined by measuring the change of the voltage in real time. When the voltage ros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com