Preparation method of carboxymethyl chitosan gel beads coated with nano iron

A technology of carboxymethyl chitosan gel balls and carboxymethyl chitosan, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problem of poor stability and nano iron It is not easy to oxidize and other problems, so as to improve the reactivity, enhance the ability of environmental repair, and improve the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

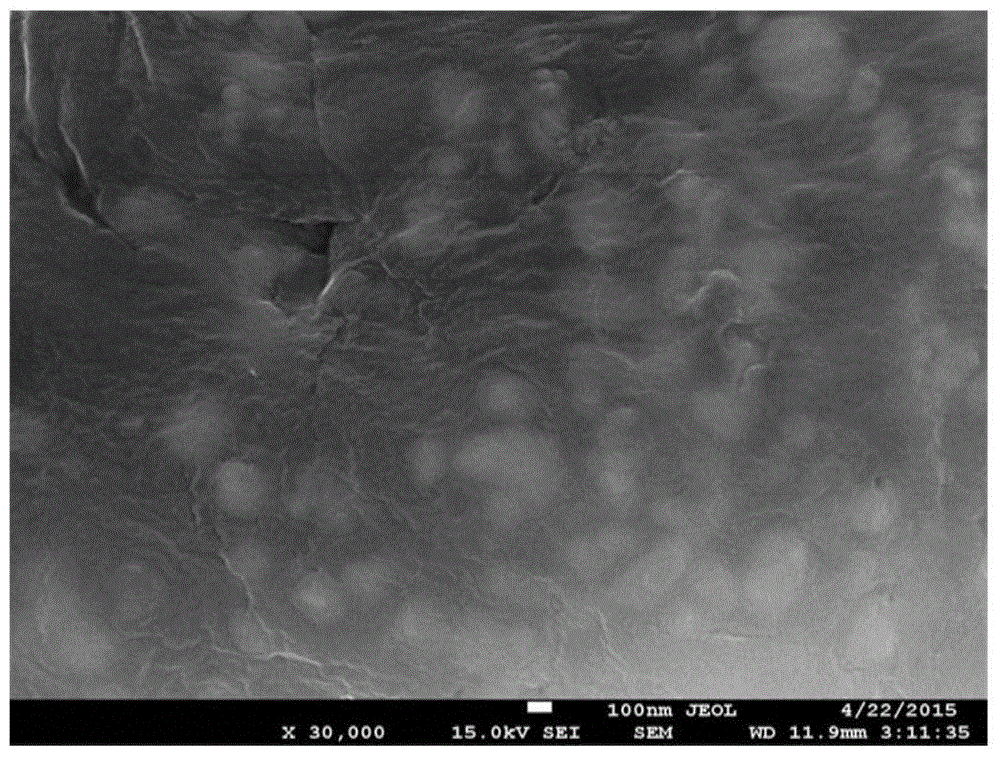

[0033] Weigh 1.5 g of carboxymethyl chitosan in a 100 mL plastic beaker, add 48.5 mL of deoxygenated water and magnetically stir to dissolve, and the solution mass concentration is 3.0%. Pour the solution into a freshly prepared 1.0 g nano-iron plastic beaker, stir ultrasonically for 5-10 min under nitrogen protection, and then use a pipette to pipette 1 mL of nano-iron carboxymethyl chitosan solution that is uniformly mixed and drop into 5.0 % calcium chloride solution to form gel balls, and after solidification for 1 hour, wash with deoxygenated water three times for preservation. The gel balls prepared under this condition have poor spheroidity, low mechanical strength, Cr 6+ The removal rate is low.

Embodiment 2

[0035] Weigh 4.5 g of carboxymethyl chitosan in a 100 mL plastic beaker, add 45.5 mL of deoxygenated water and magnetically stir to dissolve, and the solution mass concentration is 9.0%. Pour the solution into a plastic beaker with 1.0 g of nano-iron just prepared, stir ultrasonically for 5-10 min under the protection of nitrogen, then pipette 1 mL of nano-iron carboxymethyl chitosan solution which is uniformly mixed and drop into Gel balls are formed in 5.0% calcium chloride solution, and after curing for 1 hour, they are washed with deoxygenated water for three times and preserved. The gel balls prepared under this condition have poor ball-forming properties, tailing phenomenon, high mechanical strength, Cr 6+ The removal rate is high.

Embodiment 3

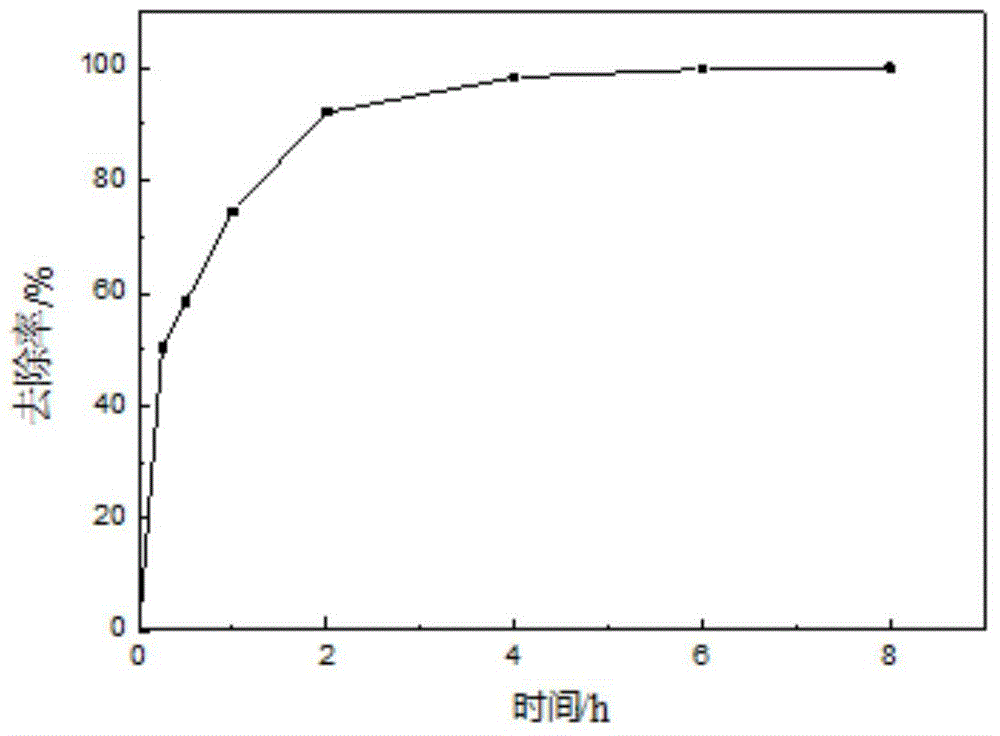

[0037] Weigh 2.5g of carboxymethyl chitosan in a 100mL plastic beaker, add 47.5mL of deoxygenated water and magnetically stir to dissolve, the solution mass concentration is 5.0%. Pour the solution into a freshly prepared 1.0 g nano-iron plastic beaker, stir ultrasonically for 5-10 min under nitrogen protection, and then use a pipette to pipette 1 mL of nano-iron carboxymethyl chitosan solution that is uniformly mixed and drop into 5.0 % calcium chloride solution to form gel balls, and after solidification for 1 hour, wash with deoxygenated water three times for preservation. The gel balls prepared under this condition have good spheroidity, high mechanical strength, Cr 6+ The removal rate is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of carboxylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com