Gravel masonry dam material filling construction method in cold region

A technology for sand and gravel dams and cold regions. It is applied in the direction of dams, barrages, and weirs. It can solve the problems of affecting the quality of dam filling, high water content of sand and gravel, and difficulty in rolling and compacting, so as to facilitate paving. Rolling, wide range of material sources, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

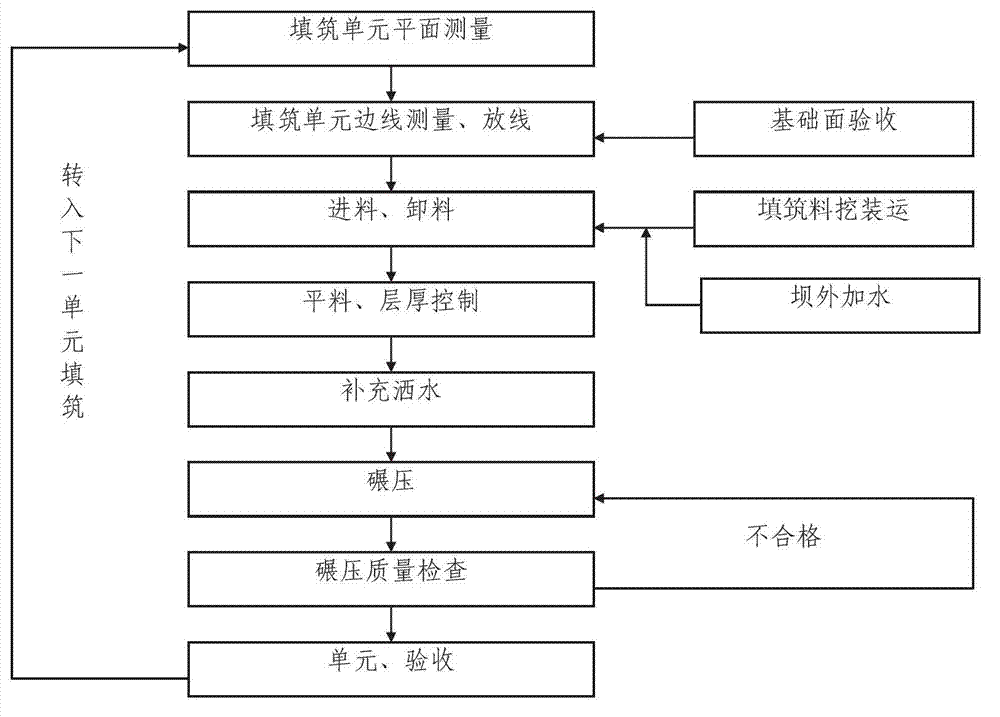

[0022] The following will be described in conjunction with the accompanying drawings and specific embodiments.

[0023] The main process of sand and gravel dam shell filling includes transportation, paving, watering, rolling, testing, etc. Through on-site rolling tests, the optimal water content of sand and gravel materials is determined, and the rolling parameters corresponding to different water contents are determined at the same time. And conduct field tests in low temperature seasons to determine the maximum moisture content of sand and gravel filling construction in low temperature seasons to ensure the quality of filling construction in low temperature seasons. During the construction process, focus on strengthening the quality control of paving thickness, watering, rolling times, etc., and pay special attention to the quality control of key parts such as bank slopes and joints, so as to ensure the normal construction of dam filling. Construction process such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com