Medical safety injector

A safety syringe and syringe technology, applied in the field of medical devices, can solve problems such as difficulty, deviation and distortion of test results, blood cell fragmentation, etc., and achieve the effects of wide application, popularization, and simple implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

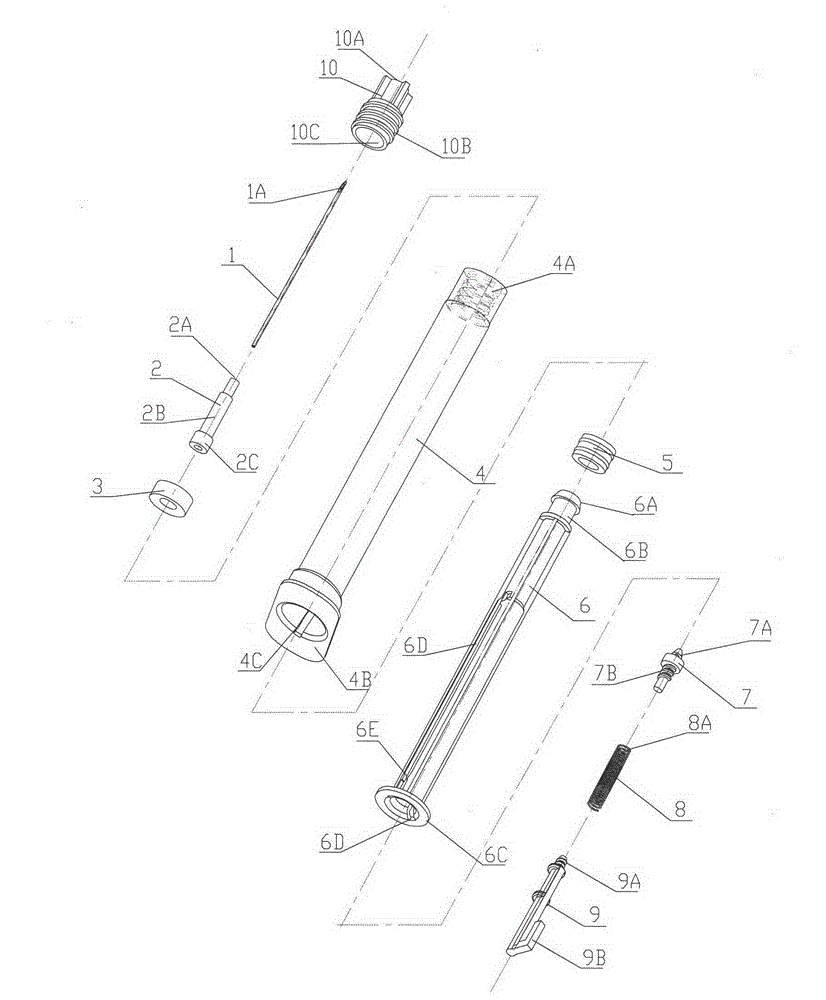

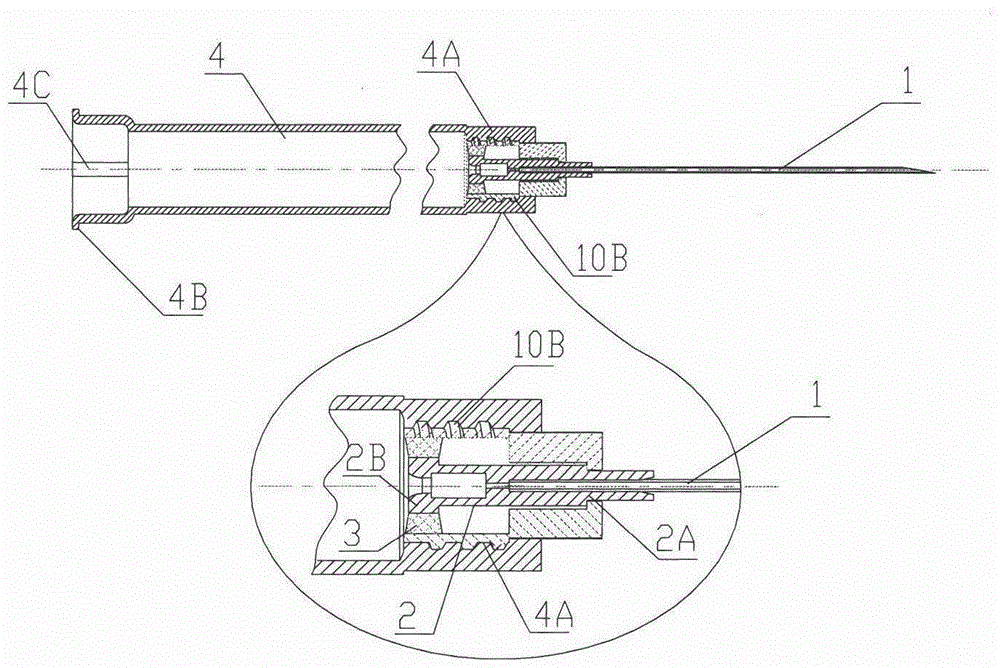

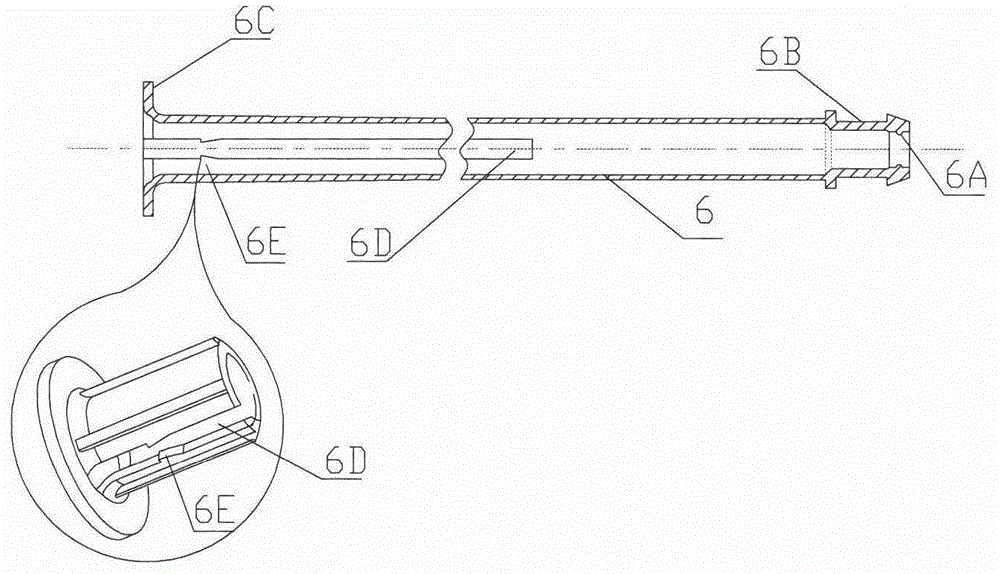

[0036] Depend on figure 1 It can be seen that the medical safety syringe of the present invention is composed of outer ferrule 10, needle tube 1, needle seat 2, damping ring 3, outer cylinder 4, piston 5, push rod 6, front plug 7, spring 8, and pull rod 9. The outer ferrule 10, the needle tube 1, the damping ring 3, and the needle seat 2 are a common injection needle assembly; the outer ferrule 10 is a cap-shaped hollow structure, and its front section has a hole 10A, which is slightly larger than the outer diameter of the upper section of the needle seat 2A; There are threads 10B; the middle and back section of the outer ferrule is hollow, and the inner diameter of the middle section is larger than the outer diameter of the middle section 2B of the needle holder, and the inner diameter of the inner hole 10C of the rear section of the outer ferrule is slightly smaller than the outer diameter of the damping ring 3, and the inner diameter of the rear section of the outer ferrule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com