Modified activated carbon material and preparing method thereof

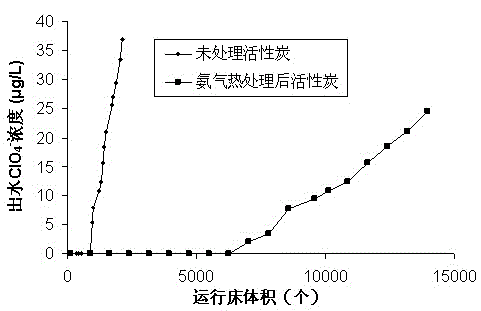

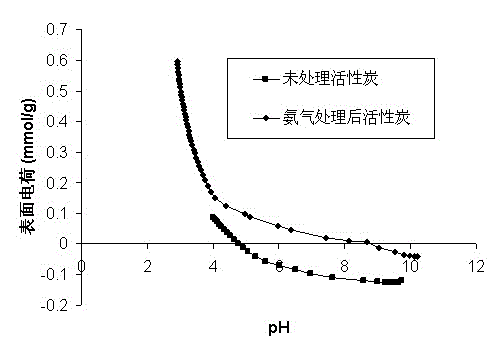

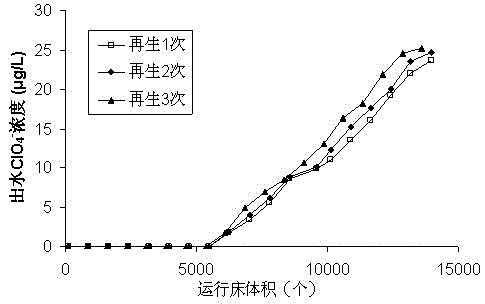

An activated carbon and modified technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as affecting the adsorption capacity of adsorbents, achieve energy saving, no fine equipment requirements, The effect of adsorption enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a modified activated carbon material, comprising the steps of:

[0029] (1) Put 1g of raw activated carbon material in the heating furnace, feed nitrogen, control the nitrogen flow rate at 70mL / min, start heating, keep the heating rate at 50°C / min, and raise the temperature to 600°C;

[0030] The raw activated carbon material is obtained by carbonizing carbonaceous material coal at a temperature of 400° C. for 3 hours under inert gas conditions, and then activated with steam at a temperature of 700° C. for 1 hour to obtain the raw activated carbon material. The pore volume is between 0.1 and 0.5mL / g, specific surface area 500-1200m 2 / g;

[0031] (2) After the temperature in step (1) rises to 600°C, stop feeding nitrogen gas and start feeding ammonia gas. The flow rate of ammonia gas is controlled at 70mL / min, and the temperature is kept at 600°C. The reaction time is 10min;

[0032] (3) After the reaction in step (2), turn off the ammonia g...

Embodiment 2

[0034] A preparation method of a modified activated carbon material, comprising the steps of:

[0035] (1) Put 1g of raw activated carbon material in the heating furnace, feed nitrogen, control the nitrogen flow rate at 70mL / min, start heating, keep the heating rate at 50°C / min, and raise the temperature to 600°C;

[0036] Described raw material activated carbon material is with embodiment 1;

[0037] (2) After the temperature in step (1) rises to 600°C, stop feeding nitrogen gas and start feeding ammonia gas. The flow rate of ammonia gas is controlled at 70mL / min, and the temperature is kept at 600°C. The reaction time is 30min;

[0038] (3) After the reaction in step (2), turn off the ammonia gas, turn on the nitrogen gas, and the heating furnace starts to cool down at a rate of 10°C / min. When the temperature drops to room temperature, take out the treated raw activated carbon material and use it to After washing with ion water and drying, a modified activated carbon mat...

Embodiment 3

[0040] A preparation method of a modified activated carbon material, comprising the steps of:

[0041] (1) Put 1g of raw activated carbon material in the heating furnace, feed nitrogen, control the nitrogen flow rate at 70mL / min, start heating, keep the heating rate at 50°C / min, and raise the temperature to 600°C;

[0042] Described raw material activated carbon material is with embodiment 1;

[0043] (2) After the temperature in step (1) rises to 600°C, stop feeding nitrogen gas and start feeding ammonia gas. The flow rate of ammonia gas is controlled at 70mL / min, and the temperature is kept at 600°C. The reaction time is 60min;

[0044](3) After the reaction in step (2), turn off the ammonia gas, turn on the nitrogen gas, and the heating furnace starts to cool down at a rate of 10°C / min. When the temperature drops to room temperature, take out the treated raw activated carbon material and use it to After washing with ion water and drying, a modified activated carbon mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com