Natural plant based preparation method for low-cost high-efficiency catalyst for oxygen reduction reaction

A technology of natural plants and catalysts is applied in the field of preparation of low-cost and high-efficiency oxygen reduction reaction catalysts, which can solve problems such as complex preparation and achieve the effects of simple preparation, low cost and good catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention is achieved like this, and its preparation steps are as follows:

[0022] (1) Collect loofahs grown in nature and dry them;

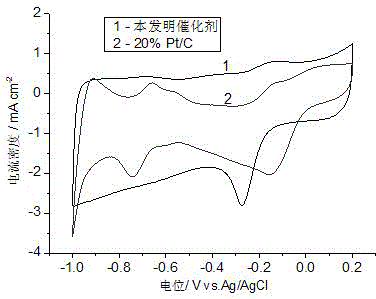

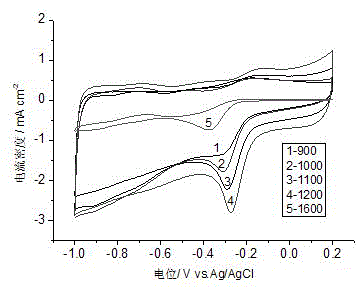

[0023] (2) Put the dried loofah in a high-temperature furnace, and under the protection of nitrogen, heat it to 1000 oC at a heating rate of 5 oC / min, and stay for a certain period of time;

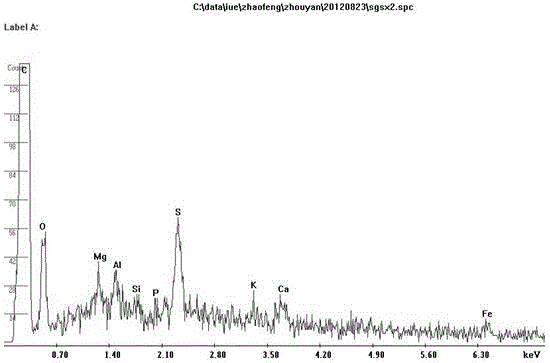

[0024] (3) Allow the electric furnace to cool naturally below 400 oC, and take out the carbonized material to obtain an oxygen reduction catalyst; the total content of nitrogen, phosphorus and sulfur in the carbonized loofah is greater than 1%.

Embodiment 2

[0026] The present invention is achieved like this, and its preparation steps are as follows:

[0027] (1) Collect loofahs grown in nature and dry them;

[0028] (2) Put the dried loofah in a high-temperature furnace, under the protection of nitrogen, heat it to 1100 oC at a heating rate of 5 oC / min, and stay for a certain period of time;

[0029] (3) Allow the electric furnace to cool naturally below 400 oC, and take out the carbonized material to obtain an oxygen reduction catalyst; the total content of nitrogen, phosphorus and sulfur in the carbonized loofah is greater than 1%.

Embodiment 3

[0031] The present invention is achieved like this, and its preparation steps are as follows:

[0032] (1) Collect loofahs grown in nature and dry them;

[0033] (2) Put the dried loofah in a high-temperature furnace, and under the protection of nitrogen, heat it to 1200 oC at a heating rate of 10 oC / min, and stay for a certain period of time;

[0034] (3) Allow the electric furnace to cool naturally below 400 oC, and take out the carbonized material to obtain an oxygen reduction catalyst; the total content of nitrogen, phosphorus and sulfur in the carbonized loofah is greater than 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com