Process for improving quality and reducing impurities of tin stone multi-metal sulfide ore tin ore concentrate and combined equipment

A combined equipment and multi-metal technology, applied in the field of metallurgy, can solve the problems of difficulty in improving tin recovery rate, increase tin loss, interference of pyrite minerals, etc., and achieve the effect of promoting recovery rate, improving recovery rate and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

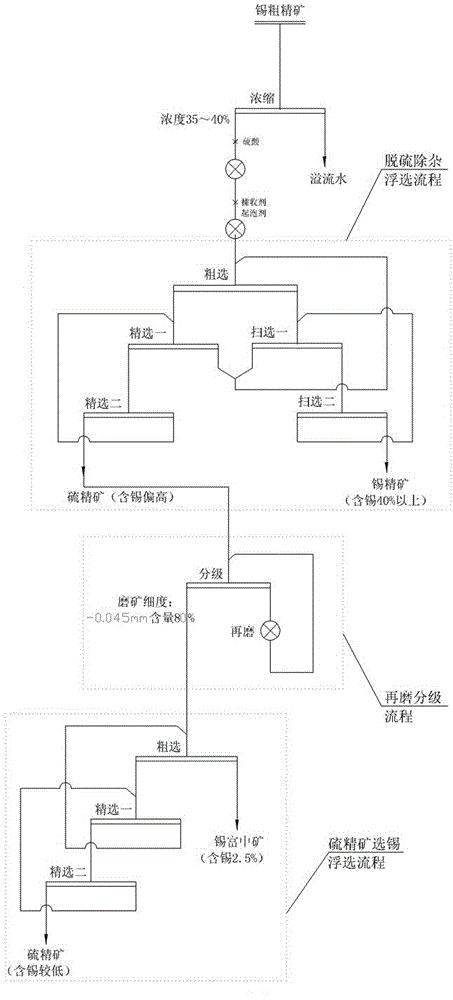

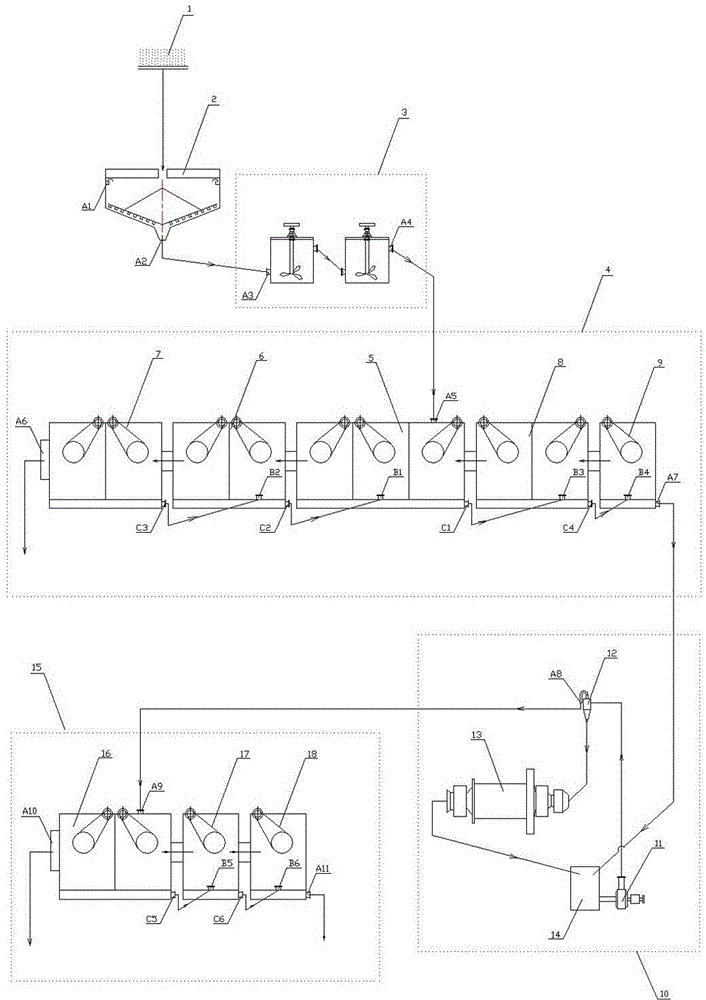

[0031] Embodiment 1: A process for improving the quality and reducing impurities of cassiterite polymetallic sulfide ore tin concentrate, comprising the following steps:

[0032] The first step: combine the tin concentrate material mainly composed of cassiterite and with a tin grade of more than 40% in the shaker concentrate belt, and the tin concentrate material mainly composed of pyrite minerals and fine-grained cassiterite with a tin grade of 5~5% in the concentrate belt. 10% of the mixed material is intercepted together to produce tin rough concentrate with a tin grade of 18-25%;

[0033] The second step: Concentrate the tin rough concentrate produced in the first step with a concentration of only 1~5% to a concentration of 35%, then enter the mixing tank, add sulfuric acid, collector, and foaming agent in turn to stir, and then enter Desulfurization and impurity removal flotation process to obtain tin concentrate products with a tin grade of more than 40% and a sulfur + a...

Embodiment 2

[0038] Embodiment 2: A process for improving the quality and reducing impurities of cassiterite polymetallic sulfide ore tin concentrate, comprising the following steps:

[0039] The first step: combine the tin concentrate material mainly composed of cassiterite and with a tin grade of more than 40% in the shaker concentrate belt, and the tin concentrate material mainly composed of pyrite minerals and fine-grained cassiterite with a tin grade of 5~5% in the concentrate belt. 10% of the mixed material is intercepted together to produce tin rough concentrate with a tin grade of 18-25%;

[0040] The second step: Concentrate the tin rough concentrate produced in the first step with a concentration of only 1~5% to a concentration of 37%, then enter the mixing tank, add sulfuric acid, collector, and foaming agent in turn to stir, and then enter Desulfurization and impurity removal flotation process to obtain tin concentrate products with a tin grade of more than 40% and a sulfur + a...

Embodiment 3

[0045] Embodiment 3: A process for improving the quality and reducing impurities of cassiterite polymetallic sulfide ore tin concentrate, comprising the following steps:

[0046] The first step: combine the tin concentrate material mainly composed of cassiterite and with a tin grade of more than 40% in the shaker concentrate belt, and the tin concentrate material mainly composed of pyrite minerals and fine-grained cassiterite with a tin grade of 5~5% in the concentrate belt. 10% of the mixed material is intercepted together to produce tin rough concentrate with a tin grade of 18-25%;

[0047] The second step: Concentrate the tin rough concentrate produced in the first step with a concentration of only 1~5% to a concentration of 40%, and then enter the mixing tank, add sulfuric acid, collector, and foaming agent in turn to stir, and then enter Desulfurization and impurity removal flotation process to obtain tin concentrate products with a tin grade of more than 40% and a sulfur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com