Composite bacterial coal biological flocculant and method for purifying slime water by same

A technology of biological flocculants and composite bacteria, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve complex problems, high production costs, difficult management, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 obtains Aspergillus niger and Phanerochaete chrysosporium culture stoste and each part of culture stoste

[0028] 1. Obtain Aspergillus niger culture stock solution

[0029] Aspergillus niger medium formula: 20% potato juice 1000mL, glucose 20g, KH 2 PO 4 3g, MgSO 4 ·7H 2 O 1.5g, vitamin B1 8mg, pH=6 (preparation of 20% potato juice: take 200g peeled potatoes, cut into small pieces, add 1000mL of water and boil for 20min, filter out the potato pieces, and make up the filtrate to 1000mL).

[0030] Based on the above-mentioned Aspergillus niger culture medium formula, obtain following 3 kinds of liquid culture medium:

[0031] Medium No. 1: 90% by volume of Aspergillus niger medium and 10% by volume of slime water were mixed.

[0032] Medium No. 2: Mix 70% by volume of Aspergillus niger medium and 30% by volume of slime water.

[0033] Medium No. 3: Mix 40% by volume of Aspergillus niger medium and 60% by volume of slime water.

[0034] Each culture me...

Embodiment 2

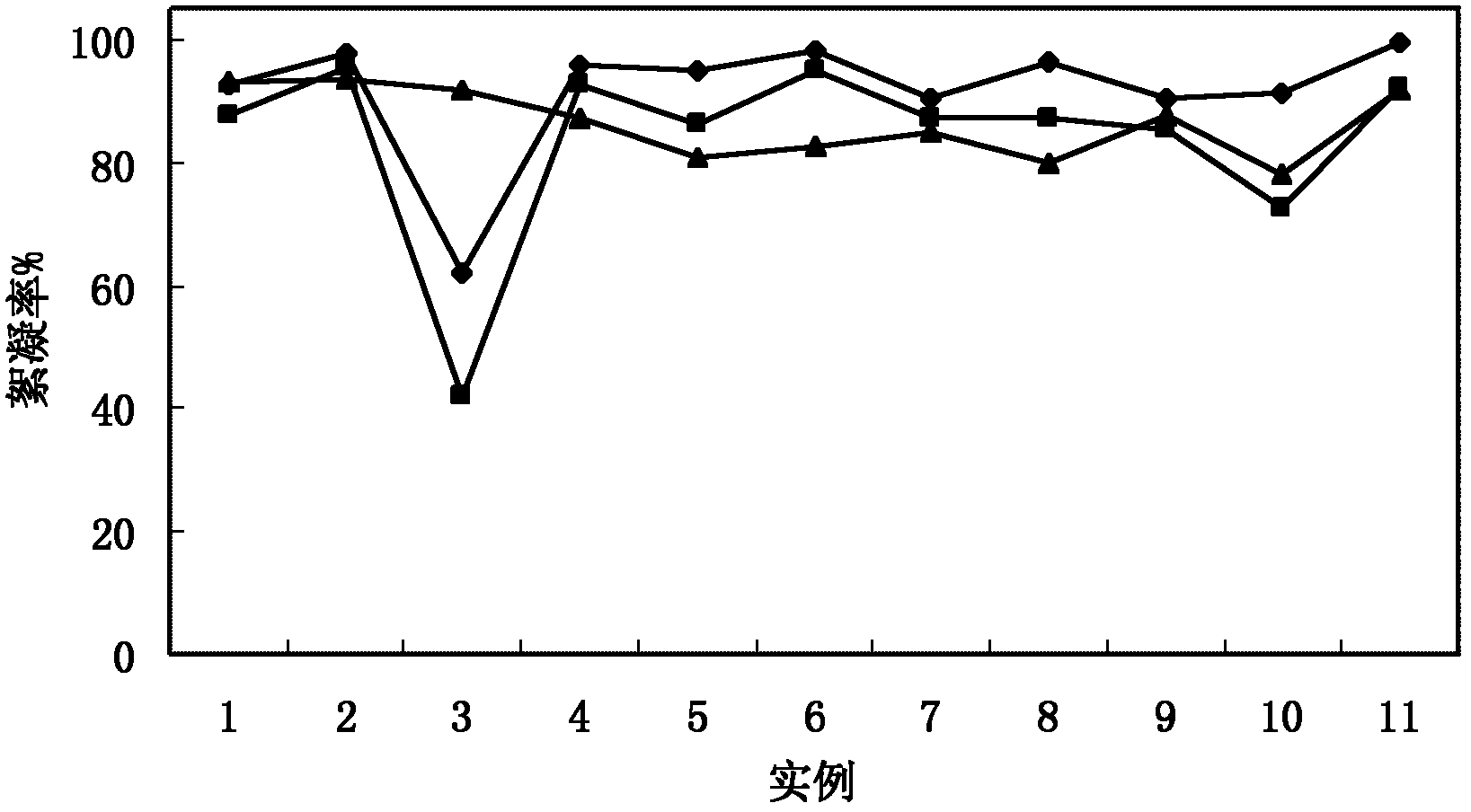

[0045] Example 2 Purification of coal slime water by composite bacterial strain coal bioflocculant

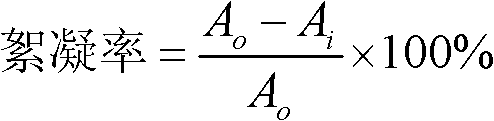

[0046] The flocculation effect of the coal bioflocculant in purifying slime water is measured by the flocculation rate, the higher the flocculation rate, the better the flocculation effect. The formula for calculating the flocculation rate is:

[0047]

[0048] In the formula: A o - OD of supernatant without adding coal bioflocculant 660 value;

[0049] A i -Supernatant OD after adding coal bioflocculant flocculation 660 value.

[0050] In order to ensure that the absolute amount of flocculation of coal slime particles is comparable, the total volume of each reaction system is kept at a fixed amount in the following examples.

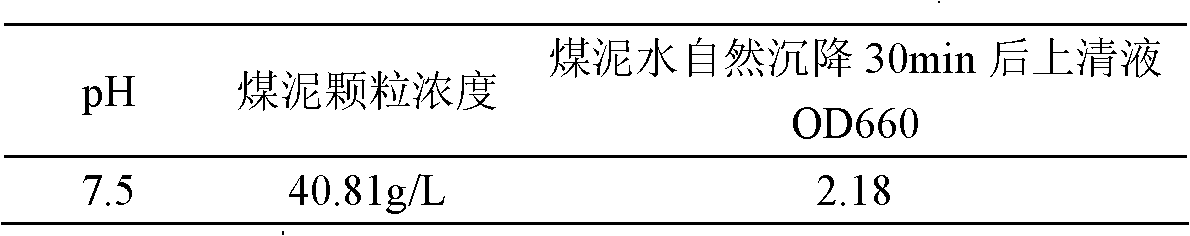

[0051] The coal slime water used in the following examples is taken from the flotation tailing coal slime water of Huainan Wangfenggang Coal Preparation Plant. The relevant properties of slime water are shown in Table 2:

[0052] Table 2

[0...

example 1

[0058] 1) Get 90mL of uniformly stirred coal slime water, then add 2% by mass of CaCl 2 Coagulant aid 2mL, stir with a magnetic slow speed stirrer for 1min;

[0059] 2) Add 3mL of coal bioflocculant, add coal slime water to 100mL, adjust the pH value of coal slime water to 7 with a pen-type pH meter, and then stir slowly for 1min with a magnetic stirrer. The coal bioflocculant includes Aspergillus niger stock solution centrifugation Supernatant 1.5mL and Phanerochaete chrysosporium stock solution centrifuged supernatant 1.5mL, the active culture time of Aspergillus niger and Phanerochaete chrysosporium was 2 days.

[0060] 3) Stand still for 30 minutes to absorb the supernatant, measure the absorbance value of the supernatant at 660 nm with a UV-5100 ultraviolet spectrophotometer, and obtain a flocculation rate of 92.48%. When other conditions remain unchanged, the coal bioflocculant is replaced with 3ml Aspergillus niger stock solution centrifuged supernatant, and the floccu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com