Dedicated filler for constructed wetland and preparation method for filler

A technology of constructed wetland and clay, which is applied in chemical instruments and methods, other chemical processes, biological water/sewage treatment, etc., can solve the problems of industrial solid waste such as red mud being difficult to handle, and is convenient for engineering construction and later operation and maintenance. , low cost, easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

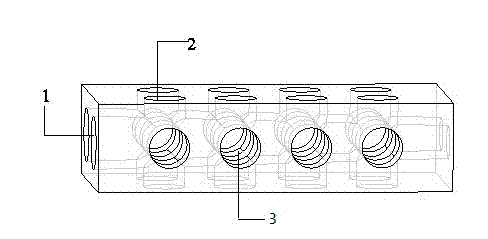

[0015] Embodiment 1: The components of the filler and the weight percent examples of each component are: dry sludge 13%, clay 80%, grass reed or reed 7%; described grass reed or reed is cut into sections, each the length of a paragraph 2.5cm ; Described clay is the mixed soil of dry weight ratio 10% red mud, 90% common clay;

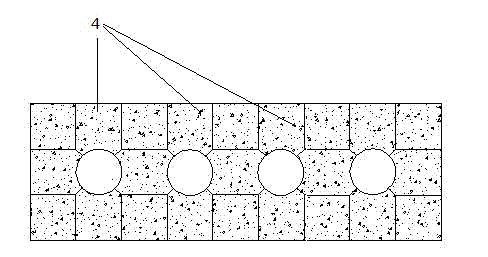

[0016] The production method of the filler: use the usual mixing method to mix dry sludge, clay and reeds or reeds, stir and mix evenly, introduce the mixed mud into the mold, and make it into a rectangular parallelepiped or cylindrical shape, with a rectangular parallelepiped in the center Or it is a cylindrical shape with holes, and the holes are perpendicular to the large surface; then it is fired in a kiln at high temperature.

[0017] The sludge hollow brick of the present invention is made by mixing residual sludge of sewage plants in different proportions with clay, grass reed or cut reed according to requirements, and then undergoing raw materi...

Embodiment 2

[0020] Embodiment 2: dry sludge 10%, clay 85%, reed or reed 5%; described reed or reed is cut into sections, the length of each section 5cm ; Described clay is the mixed soil of dry weight ratio 10% fly ash and 90% common clay.

[0021] The clay is either a mixture of red mud and clay; the clay is a mixture of fly ash and clay; the mixture is used in the same manner as the clay, and is mixed in the same proportion as the clay; Red mud and fly ash raw materials are readily available.

[0022] Others are the same as in Example 1.

Embodiment 3

[0023] Embodiment 3: dry sludge 20%, clay 70%, reed or reed 10%; described reed or reed is cut into sections, the length of each section 1cm ; The clay is a mixture of dry weight ratio of 20% red mud and 80% common clay.

[0024] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com