Waterproof adhesive mortar for external thermal insulation of external wall

A technology for external wall thermal insulation and bonding mortar, which is applied in the field of building material mortar to achieve the effects of good bonding strength, safe and hygienic construction, and outstanding waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A water-resistant adhesive mortar for exterior wall insulation, which is obtained by mixing raw materials with the following weight ratios:

[0032] 20 parts of grade 42.5 high alumina cement, 10 parts of grade 42.5 portland cement, 65 parts of 70-100 mesh washed river sand, 2 parts of heavy calcium, 2.5 parts of redispersible latex powder, 0.2 parts of methyl cellulose ether, and Disperse 0.3 part of silyl water repellent. The viscosity of a 2% aqueous solution of methyl cellulose ether at 20°C is 75,000 mPa·s.

[0033] When using, mix the water-resistant adhesive mortar for external thermal insulation with water at a mass ratio of 100:20, add water first, and then add the evenly mixed water-resistant adhesive mortar for external thermal insulation with an electric mixer while stirring, and stir thoroughly 5 After 5 minutes, let the slurry stand for 5 minutes, and then it can be used after stirring again.

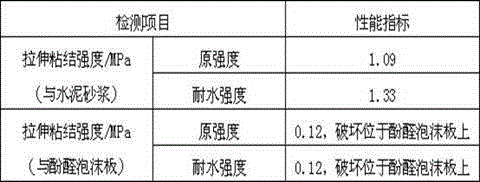

[0034] According to the performance testing method in the "Expanded...

Embodiment 2

[0038] A water-resistant adhesive mortar for exterior wall insulation, which is made by mixing raw materials with the following weight ratios:

[0039] 20 parts of 52.5 grade high alumina cement, 15 parts of 42.5 grade Portland cement, 60 parts of 70-100 mesh washed river sand, 2.8 parts of heavy calcium, 2 parts of redispersible latex powder, 0.1 part of hydroxyethyl cellulose ether and The water repellent is composed of 0.1 parts by mass. The viscosity of a 2% aqueous solution of hydroxyethyl cellulose ether at 20°C is 200,000 mPa·s.

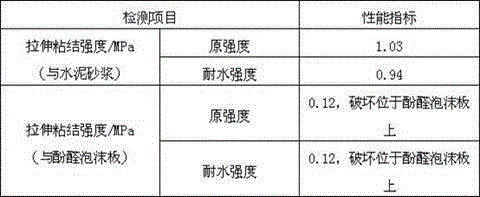

[0040] Place the above-mentioned raw materials in a mixer for pre-mixing, and the mixing time is not less than 2 minutes to facilitate uniform mixing. When in use, mix the water-resistant adhesive mortar for exterior wall insulation with water at a mass ratio of 100:20. Add water first, and then use an electric mixer while stirring to add a uniformly mixed water-resistant adhesive mortar for exterior wall insulation. After stirring for 5 minutes,...

Embodiment 3

[0045] A water-resistant adhesive mortar for external thermal insulation of external walls, which is made by mixing raw materials with the following weight ratios:

[0046] 42.5 grade high alumina cement 25 parts, 42.5 grade portland cement 10 parts, 70-100 mesh quartz sand 55 parts, heavy calcium 8 parts, redispersible latex powder 1.5 parts, methyl cellulose ether 0.3 parts and re It consists of 0.2 parts of dispersed silyl water repellent. The viscosity of a 2% aqueous solution of methyl cellulose ether at 20°C is 100,000 mPa·s.

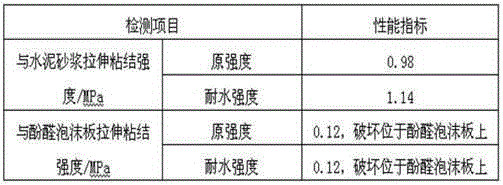

[0047] Before use, put the above-mentioned raw materials in a mixer for pre-mixing, and the mixing time is not less than 2 minutes to facilitate uniform mixing. When in use, mix the water-resistant adhesive mortar for external thermal insulation with water at a mass ratio of 100:20, add water first, and then use an electric mixer while stirring to add the evenly mixed water-resistant adhesive mortar for external thermal insulation, and stir thoroughly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com