Reaction unit for preparing low-carbon olefins

A low-carbon olefin and reaction device technology, which is applied in the direction of hydrocarbon cracking, hydrocarbon production from oxygen-containing organic compounds, ethylene production, etc., can solve the problem of low yield of low-carbon olefins, achieve high selectivity and increase yield , improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

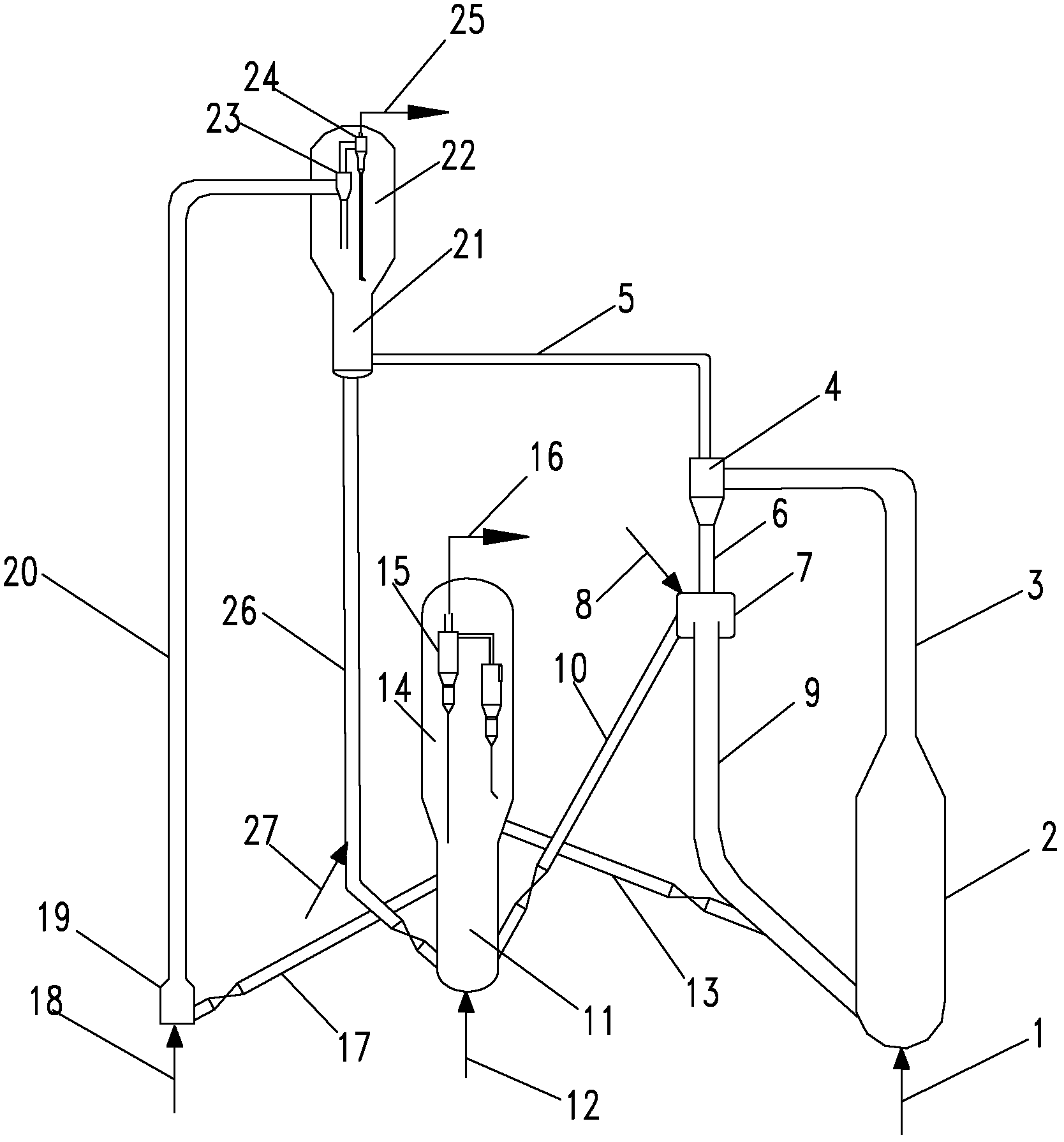

[0021] in such as figure 1 In the shown reaction device, the methanol raw material enters the fast fluidized bed reaction zone 2, contacts with the SAPO-34 catalyst, and the gas phase flow and catalyst generated enter the coarse cyclone 4, and the gas phase flow enters the settler 21 dense phase through the coarse cyclone gas phase outlet 5 section, the catalyst enters the gas-solid distribution zone 7 through the coarse rotary leg 6, and the catalyst in the gas-solid distribution zone 7 is at least divided into two parts, 20% of which enters the down-bed reaction zone 9, contacts with the methanol raw material, and the gas phase stream and the catalyst enter into the 80% of the fast bed reaction zone 2 enters the regenerator 11 for regeneration to form a regenerated catalyst. The regenerated catalyst is at least divided into two parts, 20% returns to the down-bed reaction zone 9, 80% enters the riser reaction zone 20, contacts with hydrocarbons above C4, and the generated gas...

Embodiment 2

[0023] According to the conditions and steps described in Example 1, the catalyst in the gas-solid distribution zone 7 is at least divided into two parts, 75% enters the down-bed reaction zone 9, and 25% enters the regenerator 11 for regeneration to form a regenerated catalyst, and the regenerated catalyst is at least Divided into two parts, 60% returns to the down-bed reaction zone 9, 40% enters the riser reaction zone 20, the mass content of carbon tetraolefins in the hydrocarbon stream above C4 is 75%, and the reaction condition of the riser reaction zone 20 is: the reaction temperature is 600 ℃, the reaction pressure is 0.01MPa by gauge pressure, and the gas phase velocity is 12 m / s; the reaction conditions in the down-bed reaction zone 9 are: the reaction temperature is 460°C, the reaction pressure is 0.01MPa by gauge pressure, and the gas phase velocity is 10 m / s; the reaction conditions in the fast bed reaction zone 2 are: the reaction temperature is 500°C, the reaction ...

Embodiment 3

[0025] According to the conditions and steps described in Example 1, the catalyst in the gas-solid distribution zone 7 is at least divided into two parts, 50% enters the down-bed reaction zone 9, and 50% enters the regenerator 11 for regeneration to form a regenerated catalyst, and the regenerated catalyst is at least Divided into two parts, 50% returns to the down-bed reaction zone 9, 50% enters the riser reaction zone 20, and the mass content of carbon tetraolefins in the hydrocarbon stream above C4 is 92%, and the reaction condition of the riser reaction zone 20 is: the reaction temperature is 560 ℃, the reaction pressure is 0.01MPa by gauge pressure, and the gas phase velocity is 7 m / s; the reaction conditions in the down-bed reaction zone 9 are: the reaction temperature is 440°C, the reaction pressure is 0.01MPa by gauge pressure, and the gas phase velocity is 6.6 m / s; the reaction conditions of the fast bed reaction zone 2 are: the reaction temperature is 450°C, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com