Method for preparing vilazodone or hydrochloride thereof

A kind of technology of vilazodone and compound, applied in the field of preparing vilazodone or its hydrochloride, can solve problems such as low reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

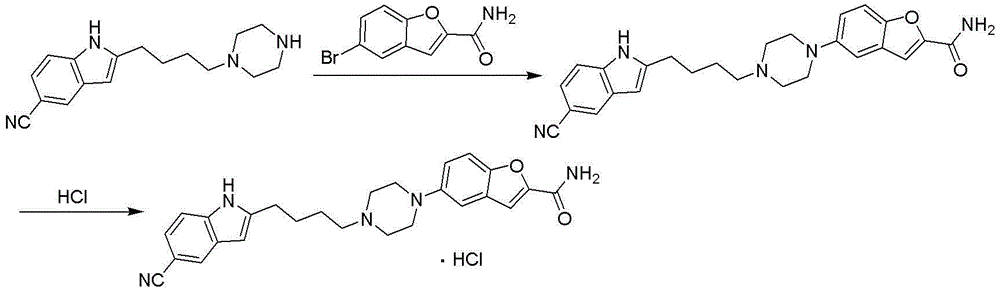

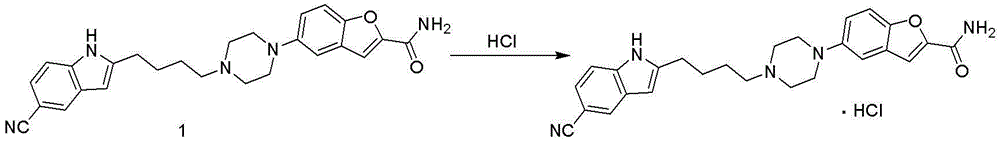

Method used

Image

Examples

Embodiment 1

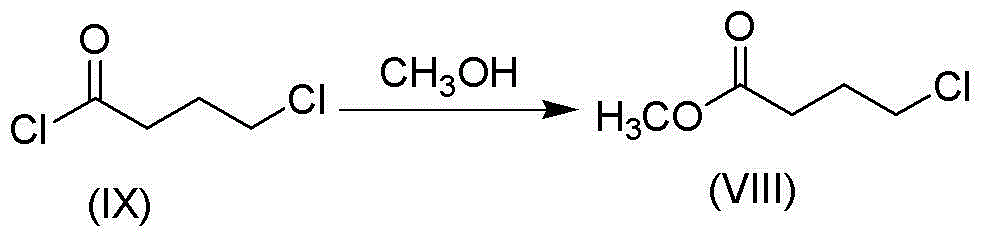

[0079] Preparation of methyl 4-chlorobutyrate

[0080] Take 49.8g of potassium carbonate in 400ml of methanol, cool to 0-5°C with an ice-water bath, add 42.3g of 4-chlorobutyryl chloride dropwise, heat to reflux for 4 hours after the addition, then filter, and distill the filtrate under reduced pressure to obtain 41.2g of crude product , used directly in the next reaction.

[0081] ESI-MS[M+H] + :137.04

[0082] 1 H-NMR (CDCl 3 ): δ1.92-1.96 (m, 2H), 2.31 (t, 2H), 3.30 (t, 2H), 3.68 (s, 3H).

Embodiment 2

[0084] Preparation of 4-bis(2-hydroxyethyl)aminobutyric acid methyl ester

[0085] The 41.2g crude product of methyl 4-chlorobutyrate prepared by the previous step reaction was dissolved in 400ml of acetonitrile, 41.5g of potassium carbonate and 31.5g of bis(2-hydroxyethyl)amine were added, heated to reflux for 12 hours, filtered after cooling, and the filtrate was reduced Distill under pressure, add 400ml isopropanol to the residue, slowly add 30ml (37%) concentrated hydrochloric acid at room temperature, filter after the precipitation is complete, dissolve the filter cake in 200ml water, extract with 3*200ml ethyl acetate, and use anhydrous sulfuric acid for the organic phase It was dried over sodium, filtered and distilled under reduced pressure to obtain 23.4 g of product.

[0086] ESI-MS[M+H] + :206.14

[0087] 1 H-NMR (CDCl 3 ): δ1.68-1.72 (m, 2H), 2.20 (t, 2H), 2.34 (t, 2H), 2.52 (t, 4H), 3.56 (t, 4H), 3.68 (s, 3H).

Embodiment 3

[0089] Preparation of 4-bis(2-chloroethyl)aminobutyric acid methyl ester

[0090] Take 20.5g of 4-bis(2-hydroxyethyl)aminobutyric acid methyl ester and 30.0g of pyridine and dissolve it in 320ml of tetrahydrofuran, cool to 0-5°C, add 27.5g of phosphorus trichloride dropwise, after the addition, heat Reflux for 4 hours, filter after cooling, distill the filtrate under reduced pressure, add 200ml ethyl acetate and 100ml ice water to the residue, adjust the pH to about 7 with 1N sodium hydroxide solution, separate the liquids, dry the organic phase with anhydrous sodium sulfate and filter , The filtrate was evaporated to dryness under reduced pressure to obtain 17.4 g of product.

[0091] ESI-MS[M+H] + :242.07

[0092] 1 H-NMR (CDCl 3 ): δ1.71-1.76 (m, 2H), 2.22 (t, 2H), 2.33 (t, 2H), 2.53 (t, 4H), 3.55 (t, 4H), 3.69 (s, 3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com