Application of Bacillus subtilis in high-yield adenosine and acetoin co-production

The technology of Bacillus subtilis and acetoin is applied in the application field of Bacillus subtilis in high-yield adenosine and co-production of acetoin, which can solve the problems of low utilization rate of raw materials and high cost, and achieve extensive culture conditions and high-yield traits. The effect of stabilizing and improving product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Slant medium: glucose 15g / L, peptone 10g / L, yeast extract 5g / L, corn steep liquor 10ml / L, MgSO 4 ·7H 2 O 0.1g / L, NaCl 3g / L, guanosine 0.03g / L, agar 15g / L, the rest is water, pH7.0;

[0035] Seed medium: glucose 15g / L, peptone 10g / L, yeast extract 10g / L, corn steep liquor 10ml / L, MgSO 4 ·7H 2 O 0.1g / L, NaCl 4g / L, guanosine 0.03g / L, the rest is water, pH7.0;

[0036] Fermentation medium: glucose 80g / L, yeast extract 15g / L, (NH 4 ) 2 SO 4 16g / L, urea 3g / L, KH 2 PO 4 4g / L, KCl 4g / L, MgSO 4 ·7H 2 O 0.5g / L, MnSO 4 ·H 2 O 0.01g / L, soybean cake hydrolyzate 20ml / L, CaCO 3 30g / L, the rest is water, pH7.0;

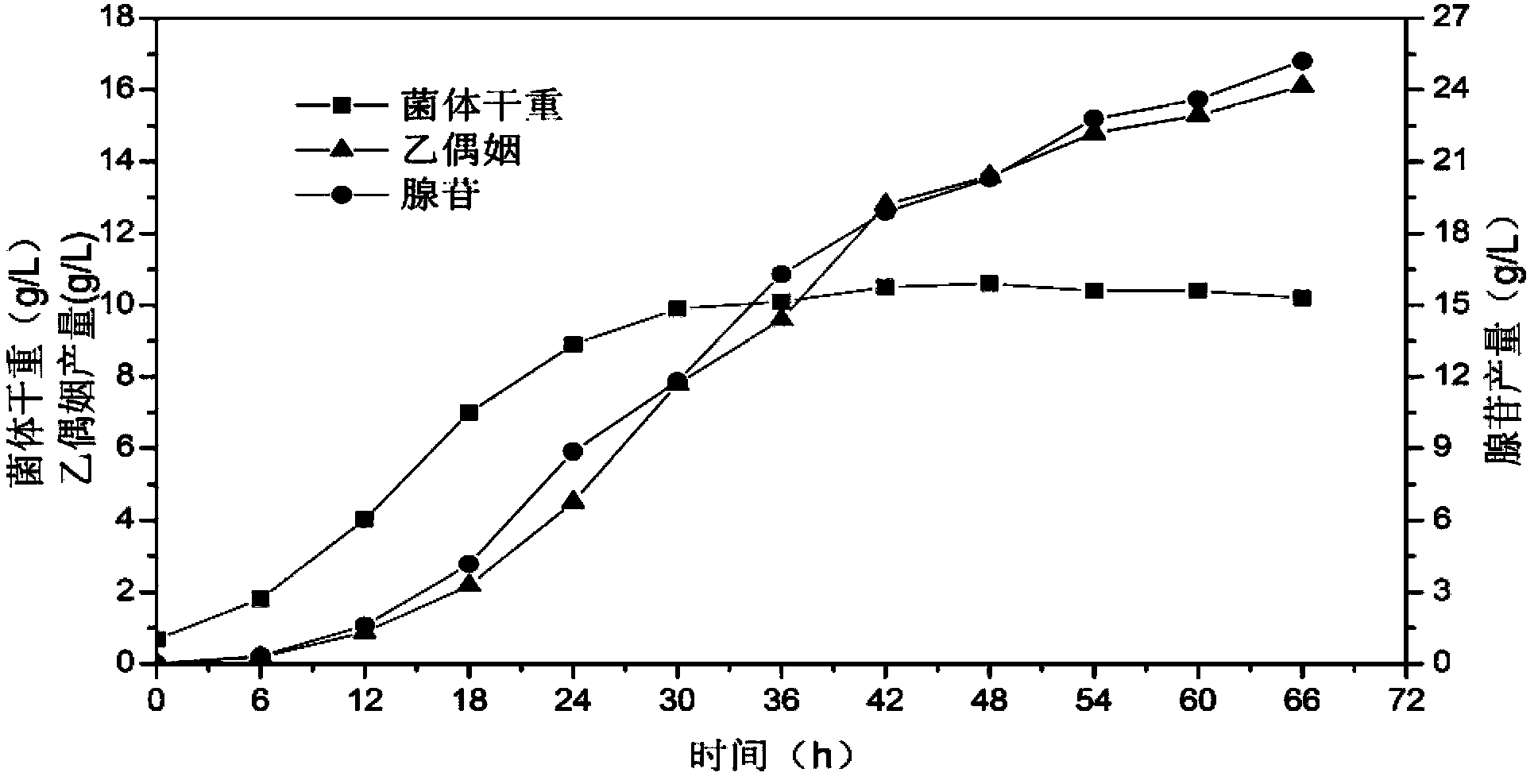

[0037] The strain A409 was transferred from the slant to a 500mL shake flask containing 30mL liquid seed medium, and cultured on a reciprocating shaker at 200rpm at 32°C for 20 hours. Transfer 3mL to a 500mL shake flask containing 30mL liquid fermentation medium, and ferment and culture on a shaker at 250rpm at 33°C for 66 hours. The yield of adenosine reached...

Embodiment 2

[0039] Fermentation medium: glucose 100g / L, yeast extract 15g / L, (NH 4 ) 2 SO 4 16g / L, urea 3g / L, KH 2 PO 4 4g / L, KCl 4g / L, MgSO 4 ·7H 2 O 0.5g / L, MnSO 4 ·H 2 O 0.01g / L, soybean cake hydrolyzate 20ml / L, CaCO 3 30g / L, the rest is water, pH7.0;

[0040] The strain A409 was transferred from the slant to a 500mL shake flask filled with 30mL liquid seed medium (same as Example 1), and cultured on a reciprocating shaker at 200rpm at 32°C for 20 hours. Transfer 2 mL to a 500 mL shake flask containing 20 mL of liquid fermentation medium, and ferment and culture on a shaker at 250 rpm at 33°C for 66 hours. The yield of adenosine reached 21.6g / L, and that of acetoin reached 13.6g / L.

Embodiment 3

[0042] Synthesize adenosine with Bacillus subtilis A409 in a 5L fermenter, prepare seed culture medium, formula and culture method are the same as embodiment 1, prepare fermentation culture medium, formula and culture method are the same as embodiment 2, the seed liquid is pressed the volume of fermented liquid 10% (v / v) inoculum was added to the cooled fermentation medium, the volume of the fermentation medium was 3L, the ventilation volume was controlled at 2vvm, the stirring speed was 500rmp, and the pH was adjusted to 6.5 with 20% ammonia water, at 35°C Fermented for 66h, the content of adenosine in the fermented liquid obtained at last is 23g / L, and the content of acetoin is 15g / L;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com