Desizing method of fabric

A fabric and desizing technology, applied in the field of dyeing and finishing, can solve the problems of low desizing rate and narrow application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

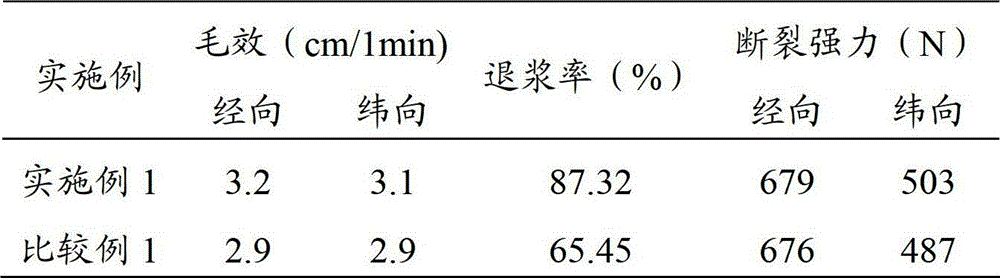

Embodiment 1

[0053] The all-cotton carding that specification is 8S * 8S 48 * 3263 " is turned over and seamed, then the all-cotton carding that obtains is placed in the singeing treatment machine and carries out singeing treatment, and the parameter of described singeing treatment is : The vehicle speed is 120±2m / min; 1 # The air pressure at the burner is 29±1mbar, and the natural gas pressure is 25±1mbar; 2 # The air pressure at the crater is 29±1mbar, the natural gas pressure is 25±1mbar; the singeing method is through burning (two positive and two reverse); the natural gas pressure is 0.11±0.01Mpa; the steam pressure of the dryer is 0.10±0.05Mpa; the steam pressure of the fire extinguishing box is 0.02±0.01Mpa; paddle pressure is 0.3±0.05Mpa; tension frame pressure is 0.25±0.05Mpa, so that the singeing level of the fabric is 4 or above;

[0054] The present invention places the obtained cotton carded through the singeing treatment in a plasma treatment machine for plasma treatment, an...

Embodiment 2

[0065] The all-cotton carding that specification is 8S * 8S 48 * 3263 " is turned over and seamed, then the all-cotton carding that obtains is placed in the singeing treatment machine and carries out singeing treatment, and the parameter of described singeing treatment is : The vehicle speed is 120±2m / min; 1 # The air pressure at the burner is 29±1mbar, and the natural gas pressure is 25±1mbar; 2 # The air pressure at the crater is 29±1mbar, the natural gas pressure is 25±1mbar; the singeing method is through burning (two positive and two reverse); the natural gas pressure is 0.11±0.01Mpa; the steam pressure of the dryer is 0.10±0.05Mpa; the steam pressure of the fire extinguishing box is 0.02±0.01Mpa; paddle pressure is 0.3±0.05Mpa; tension frame pressure is 0.25±0.05Mpa, so that the singeing level of the fabric is 4 or above;

[0066] The present invention places the obtained cotton carded through the singeing treatment in a plasma treatment machine for plasma treatment, an...

Embodiment 3

[0074] The full cotton carded with a specification of 21S×21S 108×5863″ is turned over and stitched, and then the obtained full cotton carded is placed in a singeing treatment machine for singeing treatment, and the parameter setting of the singeing treatment It is: vehicle speed is 125±2m / min; 1# burner air pressure is 29±1mbar, natural gas pressure is 25±1mbar; 2# burner air pressure is 29±1mbar, natural gas pressure is 25±1mbar. The singeing method is through burning ( Two positive and two reverse); natural gas pressure is 0.11±0.01Mpa; dryer steam pressure is 0.10±0.05Mpa; fire extinguisher steam pressure is 0.02±0.01Mpa; rolling car pressure is 0.3±0.05Mpa; 0.05Mpa, so that the singeing level of the fabric is 4 or above;

[0075] The present invention places the obtained cotton carded through the singeing treatment in a plasma treatment machine for plasma treatment, and the parameters of the plasma treatment machine are set as follows: the input voltage is 350V ~ 400V, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com