Desizing liquid and desizing method for pure cotton fabric

A pure cotton fabric desizing technology, applied in textiles, papermaking, dry-cleaning fiber products, etc., can solve problems such as hindering the contact between dyeing materials and fibers, affecting the quality of printing and dyeing products, and unfavorable printing and dyeing processing, so as to achieve improved hand feeling, high wool efficiency and High mechanical properties and high desizing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

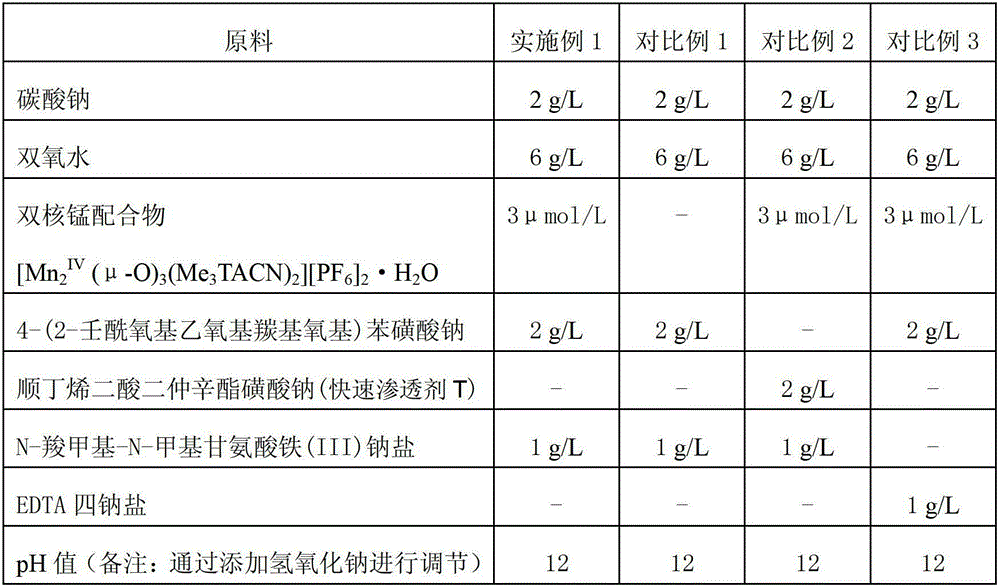

[0023] Table 1: Formulation of desizing solution (aqueous solution) for pure cotton fabric

[0024]

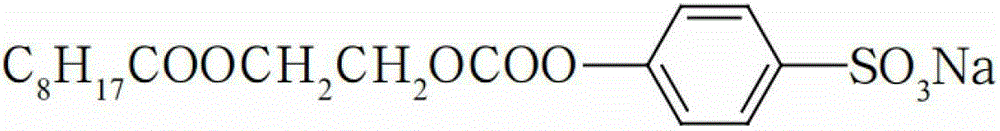

[0025] According to the corresponding data in Table 1, each raw material was weighed. The binuclear manganese complex [Mn 2 IV (μ-O) 3 (Me 3 TACN) 2 ][PF 6 ] 2 ·H 2 O, sodium carbonate, hydrogen peroxide, 4-(2-nonanoyloxyethoxycarbonyloxy) sodium benzenesulfonate and N-carboxymethyl-N-methylglycinate iron (III) sodium salt were added to water, and then added sodium hydroxide, adjust the pH value to 12, and stir evenly to obtain the desizing liquid for pure cotton fabrics.

[0026] Immerse the pure cotton fabric in the desizing solution prepared above at room temperature, the bath ratio is 1:20, raise the temperature to 70°C, and soak for 60min while keeping the temperature at 70°C; steam at 100°C for 50min, and then wash with water 40min, dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com