Production method for waterborne polyurethane synthetic leather wet process impregnated bass

A technology of water-based polyurethane and production method, applied in the field of polyurethane synthetic leather, can solve problems such as product safety and DMF pollution, achieve good physical and mechanical properties, and save the effect of DMF recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

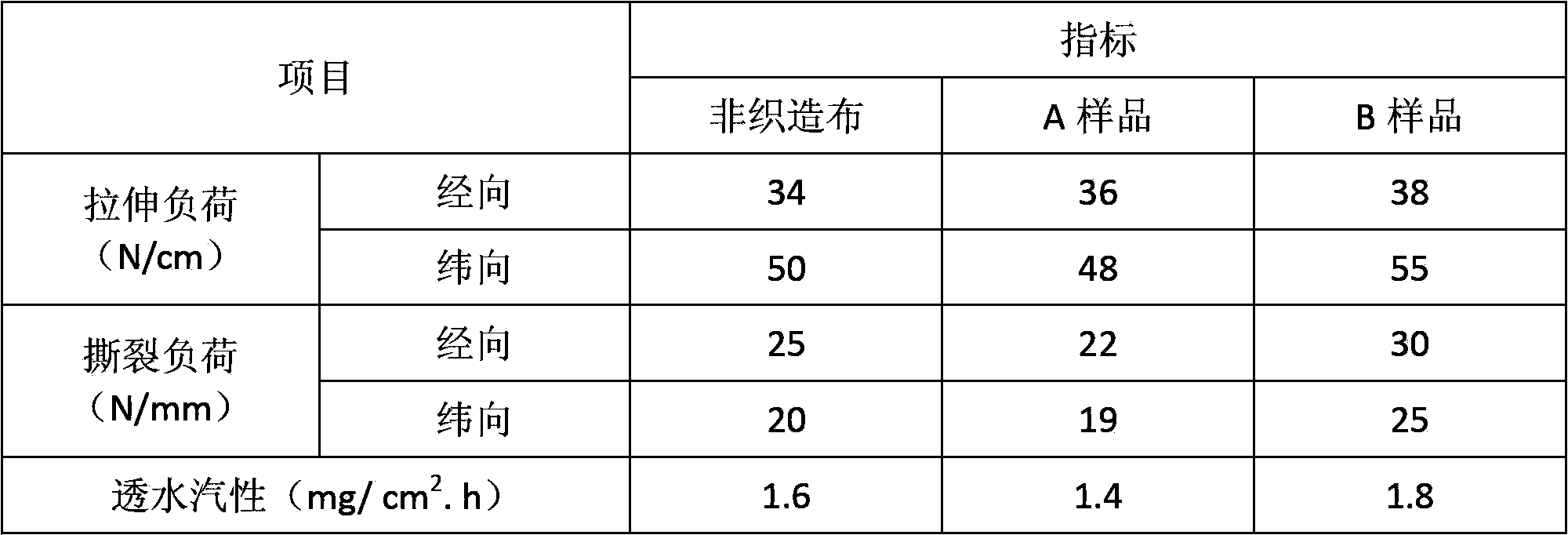

Image

Examples

Embodiment 1

[0025] 1) Preparation of dipping solution:

[0026] According to the number of parts by mass, 10 parts of anionic water-based polyurethane whose solid content is 30% of the hydrophilic group is a carboxylate group, 8 parts of light calcium carbonate with a particle diameter greater than 400 mesh, and 20 parts of water are uniformly mixed to obtain an impregnation solution;

[0027] 2) Preparation of coagulation solution:

[0028] 5 parts of demulsification cross-linking agent aluminum sulfate and 80 parts of water are mixed and stirred sequentially in parts by mass to dissolve the demulsification cross-linking agent to obtain coagulation solution;

[0029] 3) Production of water-based polyurethane synthetic leather wet impregnated bass:

[0030] First, the non-woven fabric is passed through the impregnation tank, soaked with an impregnation solution at a temperature of 20°C, and then passed through a pair of rolls to squeeze out part of the impregnation solution in the non-wo...

Embodiment 2

[0034] 1) Preparation of dipping solution:

[0035] According to the number of parts by mass, 50 parts of anionic water-based polyurethane with a solid content of 30% of the hydrophilic group being a sulfonate group, 12 parts of wood flour with a particle diameter greater than 400 mesh, and 45 parts of water were uniformly mixed to obtain an impregnation solution;

[0036] 2) Preparation of coagulation solution:

[0037] Mix and stir the mixture of 10 parts of demulsification cross-linking agent aluminum sulfate and aluminum potassium sulfate dodecahydrate and 88 parts of water successively by mass parts to dissolve the demulsification cross-linking agent to obtain coagulation solution;

[0038] 3) Production of water-based polyurethane synthetic leather wet impregnated bass:

[0039] First, pass the nonwoven fabric through the impregnation tank, soak it with the impregnating solution at a temperature of 30°C, and then pass through a pair of rolls to squeeze out part of the i...

Embodiment 3

[0043] 1) Preparation of dipping solution:

[0044] 30 parts of anionic water-based polyurethane whose solid content is 30% of the hydrophilic group is carboxylate, 10 parts of diatomite with a particle diameter greater than 400 mesh, and 30 parts of water are uniformly mixed to obtain an impregnation solution in parts by mass;

[0045] 2) Preparation of coagulation solution:

[0046] 8 parts of demulsification cross-linking agent potassium aluminum sulfate dodecahydrate, the mixture of aluminum chloride and basic aluminum formate and 90 parts of water are mixed and stirred successively in parts by mass to dissolve the demulsification cross-linking agent to obtain the coagulation solution;

[0047] 3) Production of water-based polyurethane synthetic leather wet impregnated bass:

[0048] First, pass the nonwoven fabric through the dipping tank, soak it with the impregnating solution at a temperature of 40°C, and then pass through a pair of rolls to squeeze out part of the imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com