Oil-gas organic heat transfer furnace

A heat carrier furnace, an organic technology, applied in the field of boilers, can solve the problems of uneconomical boiler exhaust gas temperature, loose boiler structure, low heat exchange efficiency, etc., and achieve the effects of compact structure, small heat loss, and increased tube wall temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

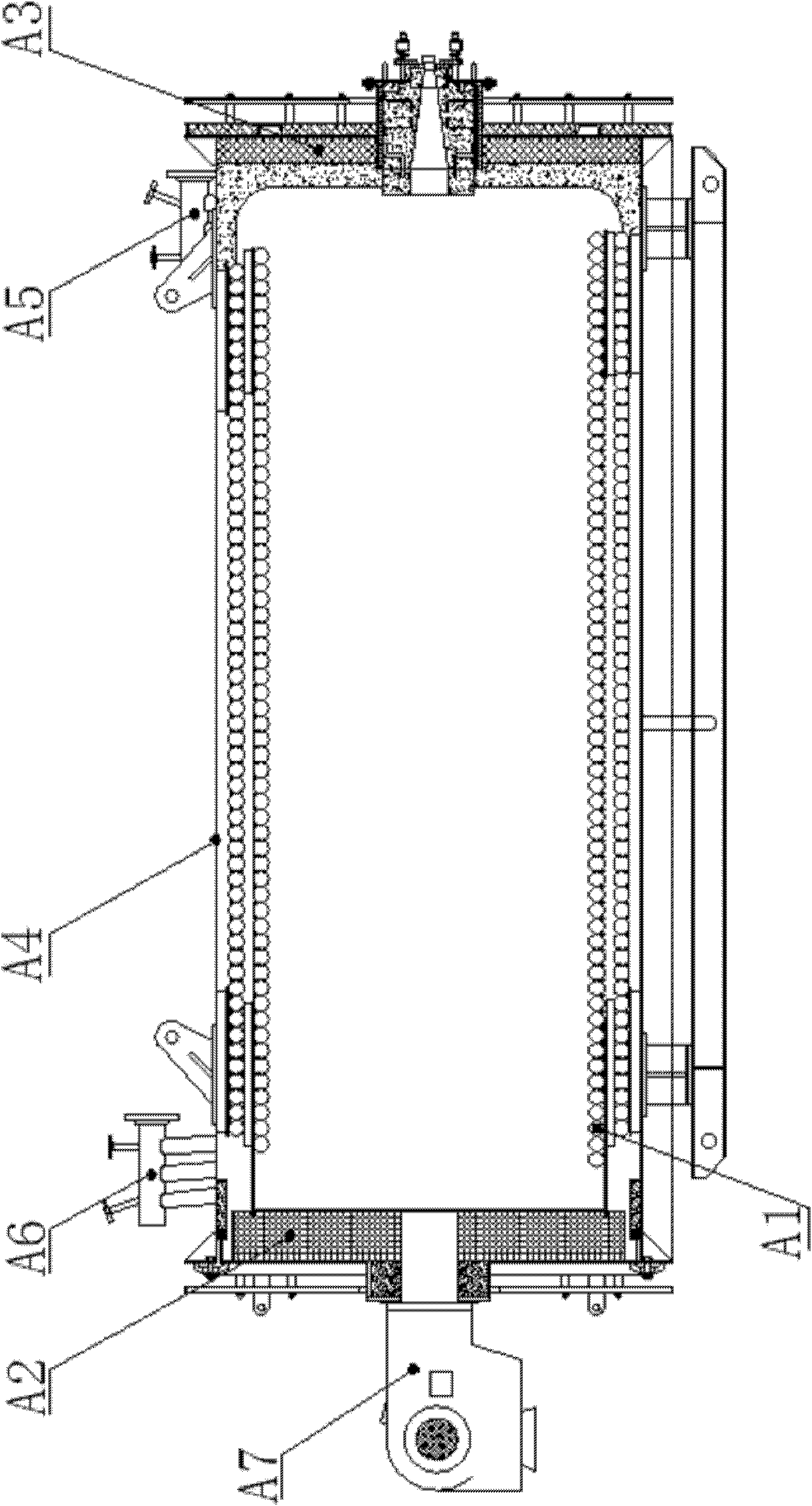

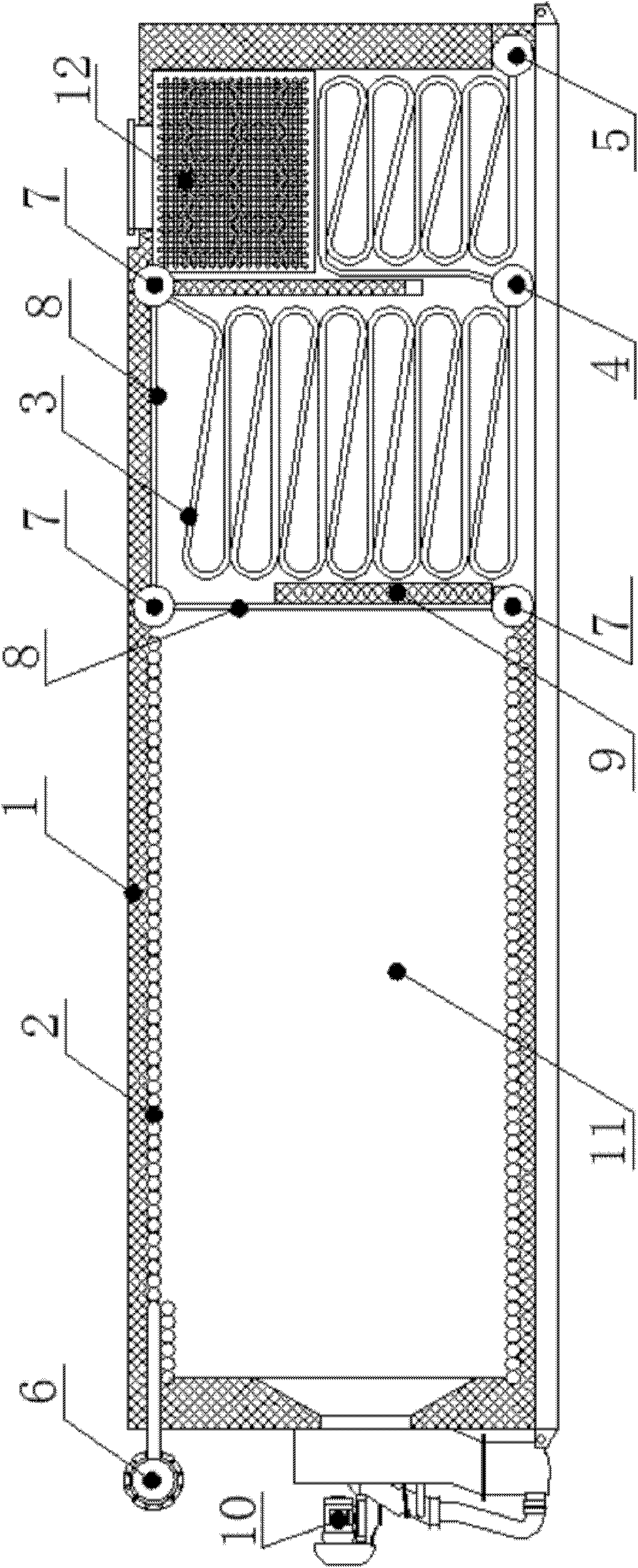

[0032] Embodiment: a fuel gas organic heat carrier furnace has a cylinder and a coil, the cylinder is a box with a square cross section, and the coil is formed by connecting several linear single tubes and the whole A square box-shaped coiled pipe 2 with a square cross section. The traditional organic heat carrier furnace adopts a cylindrical coil structure, and a large cylindrical coil structure requires large coil equipment, and multiple steel pipes are rolled as a whole, which requires high equipment and technology. The radiant section of the combustion chamber of the present invention adopts a square box-shaped coil structure, which can be welded and assembled by bending steel pipes, has low requirements on equipment, is convenient for production, and can make ordinary small and medium-sized boiler factories also Produced a large organic heat carrier furnace.

[0033] A convection section is provided, and the convection section is provided with several sections of serpent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com