Transparent flexible resistance random access memory and manufacturing method therefor

A resistive memory and transparent technology, applied in the field of flexible electronics, can solve the problems of not being completely transparent, and the electrode film is not transparent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Detection of the resistive change characteristic of parylene

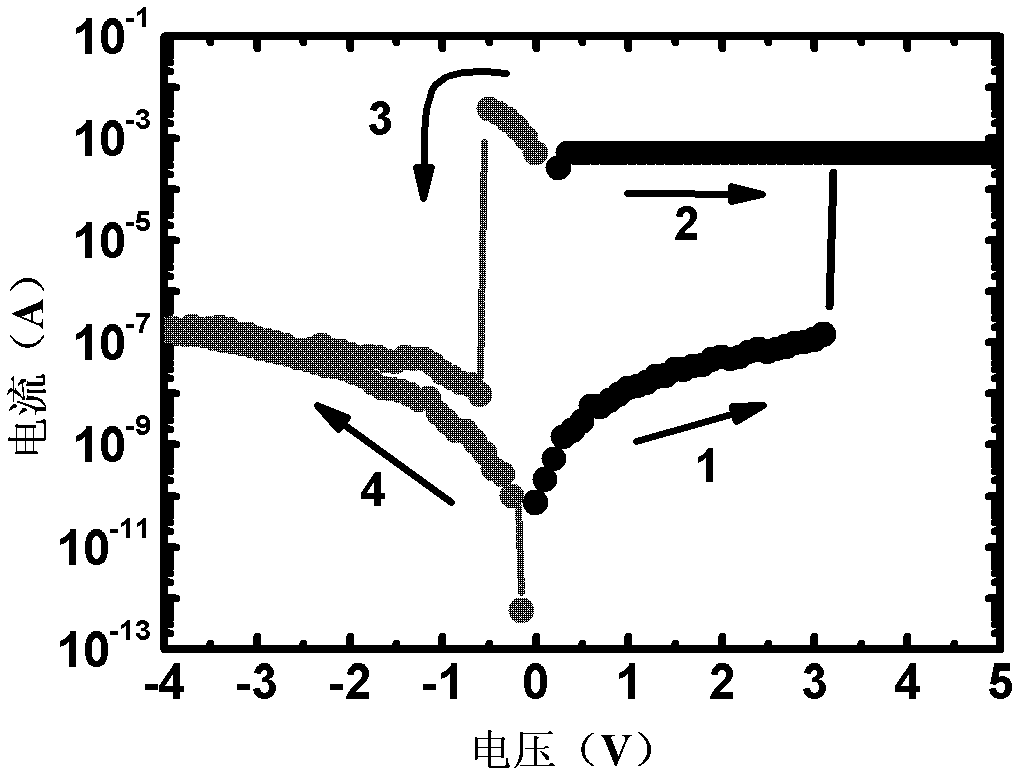

[0028] figure 1 It is the I-V characteristic diagram of the MIM structure device with Parylene-C as the middle functional layer, Al as the top electrode, and W as the bottom electrode. The mark 1 in the figure is that the device is excited by the forward voltage The transition process from high resistance state to low resistance state; 2 is the low resistance state maintenance process; 3 is the transition process of the device from low resistance state to high resistance state under the excitation of negative voltage; 4 is the high resistance state maintenance process . If the bottom electrode of the device is grounded, the voltage of the top electrode can control the resistance value of the memory, making it switch between high resistance and low resistance, that is, the transition between the two states of memory "0" and "1". The resistance ratio between the high resistance state and the low...

Embodiment 2

[0029] Example 2 Preparation of Transparent Flexible Resistive Memory

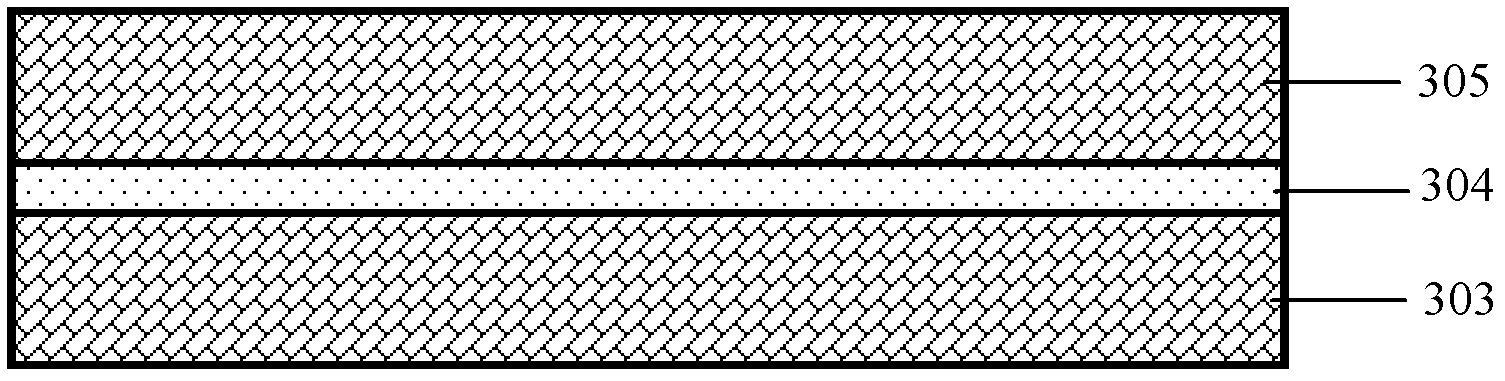

[0030] figure 2 Shown is a typical MIM capacitor structure of the transparent flexible resistive variable memory of the present invention, including a bottom electrode 303 , a middle functional layer 304 and a top electrode 305 . The preparation process of the resistive variable memory is as follows:

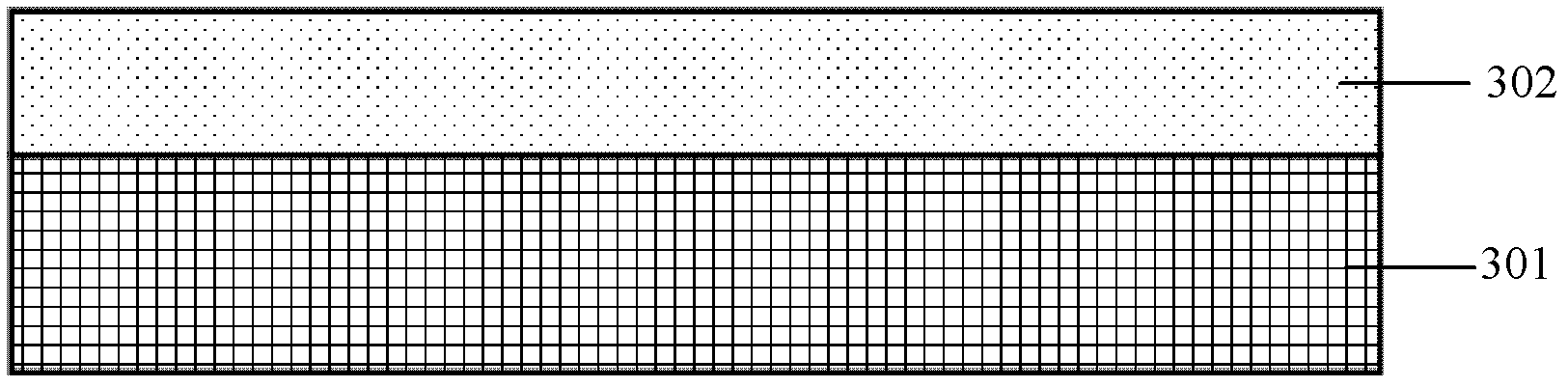

[0031] 1) Using Polymer CVD technology to grow a thick parylene-C (Parylene-C) film 302 on a silicon or glass substrate 301, with a thickness between 2 μm and 500 μm, as shown in FIG. 3(a);

[0032] 2) ITO is used as the bottom electrode 303, the bottom electrode is formed by physical vapor deposition (PVD) method or other film forming methods in IC technology, the thickness is between 200nm and 500nm, and the bottom electrode is patterned by photolithography technology , as shown in Figure 3(b) (as shown in the figure, two identical device units are fabricated on the same substrate);

[0033] 4) Utilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com