Metallic composite low-carbon magnesium carbon slag line brick and preparation method thereof

A carbon-magnesium-carbon slag wire brick and metal composite technology is applied in the field of steel-making refractory wire bricks and their preparation, which can solve the problems of low service life, polluted molten steel and high carbon content, and achieves improved product life and high temperature strength. , the effect of inhibiting the oxidation of carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Metal composite low-carbon magnesia-carbon slag wire brick, which is made of the following components by weight percentage through compression molding:

[0036] Magnesia 89% Graphite 4.0%

[0037] Metal Steel Fiber 3.0% Phenolic Resin 1.0%

[0038] Metal deoxidizer 3.0%; The metal deoxidizer includes metal aluminum powder and silicon powder, and the ratio of aluminum to silicon is 2.5:1.

[0039] The above-mentioned method for preparing metal-composite low-carbon magnesia-carbon slag wire bricks is prepared by using the above-mentioned components through mixing, trapping, pressing and curing.

Embodiment 2

[0041] Metal composite low-carbon magnesia-carbon slag wire brick, which is made of the following components by weight percentage through compression molding:

[0042] Magnesia 91% Graphite 3.5%

[0043] Metal Steel Fiber 1.5% Phenolic Resin 1.5%

[0044] Metal deoxidizer 2.5%; The metal deoxidizer includes metal aluminum powder and silicon powder, and the ratio of aluminum to silicon is 2.5:1.

[0045] The above-mentioned method for preparing metal-composite low-carbon magnesia-carbon slag wire bricks is prepared by using the above-mentioned components through mixing, trapping, pressing and curing.

Embodiment 3

[0047] Metal composite low-carbon magnesia-carbon slag wire brick, which is made of the following components by weight percentage through compression molding:

[0048] Magnesia 86% Graphite 4.5%

[0049] Metal Steel Fiber 3.5% Phenolic Resin 2.5%

[0050] Metal deoxidizer 3.5%; The metal deoxidizer includes metal aluminum powder and silicon powder, and the ratio of aluminum to silicon is 2.5:1.

[0051] The above-mentioned method for preparing metal-composite low-carbon magnesia-carbon slag wire bricks is prepared by using the above-mentioned components through mixing, trapping, pressing and curing.

PUM

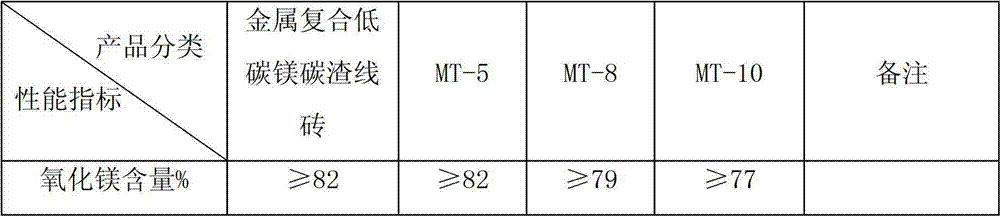

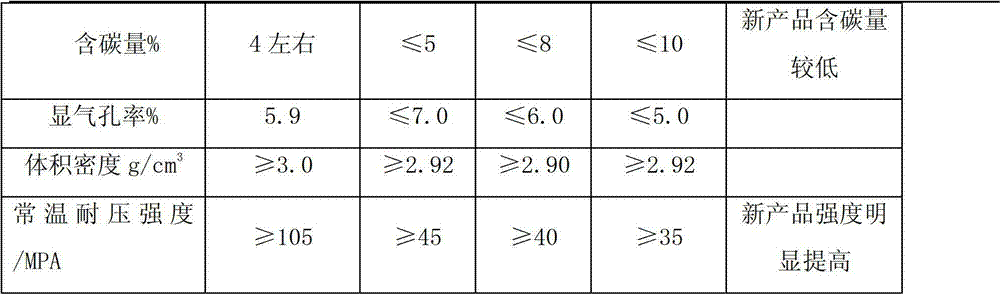

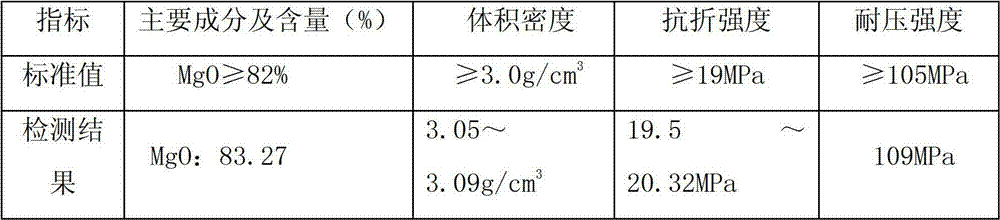

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com