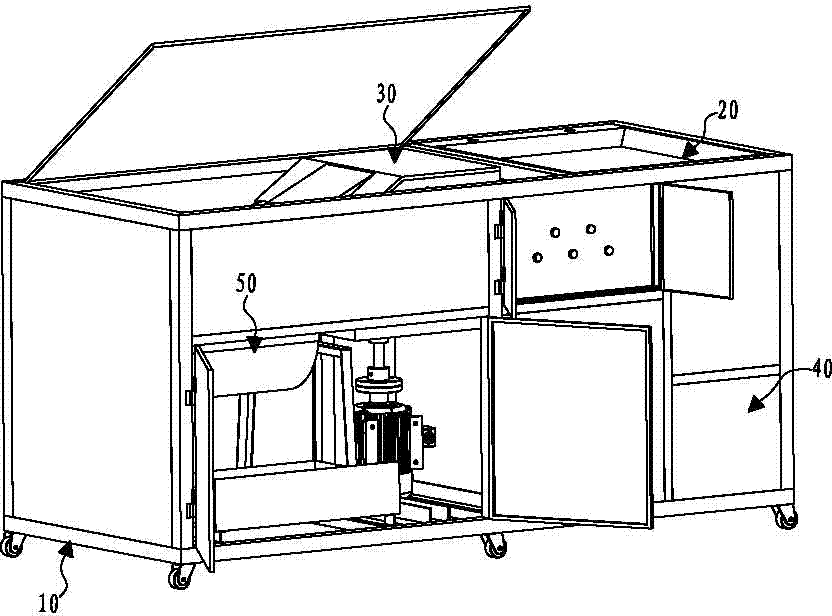

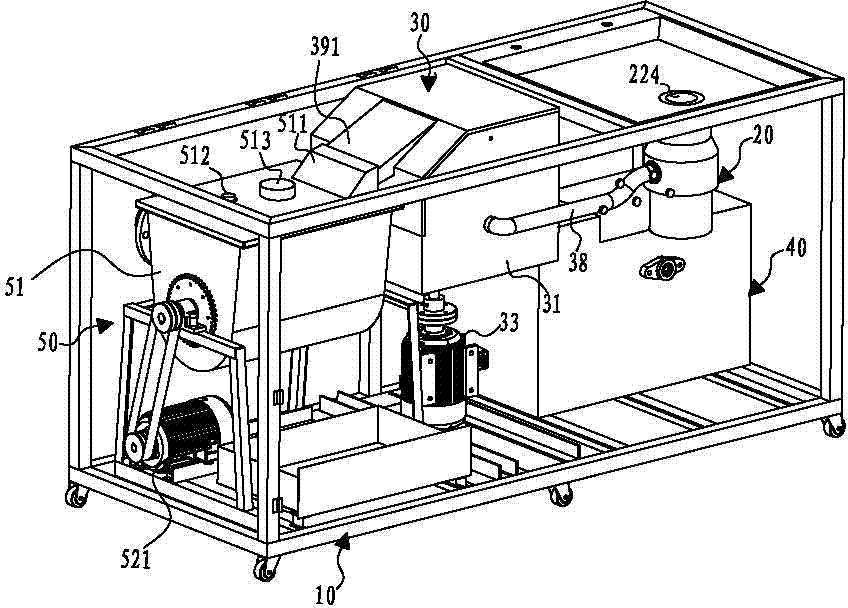

Kitchen waste recycling automatic treating all-in-one machine and treatment process thereof

A technology for automatic processing and kitchen waste, applied in the chemical industry, biological organic part processing, organic fertilizer and other directions, can solve the problems of not meeting the development needs, the overall volume is large, and the processing technology is complicated, and achieve good market promotion value and improve Treatment efficiency, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

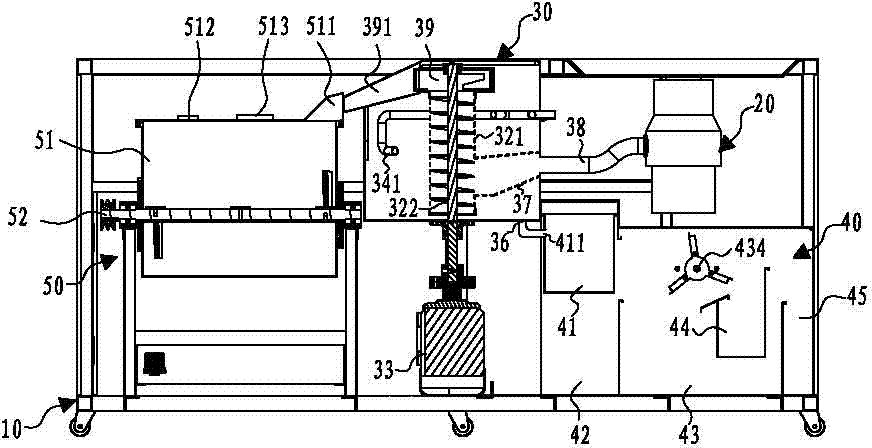

Embodiment 1

[0085] First, the food waste is collected into the crushing device for crushing. The particle size of the crushed food waste is 0.1-0.3 mm; the stirring speed is 3200 rpm, and the crushing speed is 50 kg / hour; the crushed solid-liquid mixture is sent to The solid-liquid separation is carried out in the squeezing device, and the liquid content in the solid residue after squeezing accounts for 15% of the total; the liquid squeezed out of the squeezing device enters the oil-water separation device for oil-water separation, and the solid residue enters the biochemical treatment device for treatment; among them, in the biochemical treatment In the device, the microbial agent is put into the feeding port of the fermenter, and heated and intermittently stirred in the fermenter, the heating temperature is controlled at 80°C, and the stirring speed is 60 rpm; the microbial agent is made of Composed of actinomycetes, lactic acid bacteria, yeast and photosynthetic bacteria, which are adde...

Embodiment 2

[0087] First, the food waste is collected into the crushing device for crushing. The particle size of the crushed food waste is 0.1~0.3 mm; the stirring speed is 3200 rpm, and the crushing speed is 150 kg / hour; the crushed solid-liquid mixture is sent to The solid-liquid separation is carried out in the squeezing device, and the liquid content in the solid residue after squeezing accounts for 7% of the total; the liquid squeezed out of the squeezing device enters the oil-water separation device for oil-water separation, and the solid residue enters the biochemical treatment device for treatment; among them, the biochemical treatment In the device, the microbial inoculum is put into the feeding port of the fermenter, and heated and intermittently stirred in the fermenter, the heating temperature is controlled at 30°C, and the stirring speed is 60 rpm; the microbial inoculum is made of Composed of actinomycetes, lactic acid bacteria, yeast and photosynthetic bacteria, which are a...

Embodiment 3

[0089] First, the food waste is collected into the crushing device for crushing. The particle size of the crushed food waste is 0.1-0.3 mm; the stirring speed is 3200 rpm, and the crushing speed is 100 kg / hour; the crushed solid-liquid mixture is sent to The solid-liquid separation is carried out in the squeezing device, and the liquid content in the solid residue after squeezing accounts for 9% of the total; the liquid squeezed out of the squeezing device enters the oil-water separation device for oil-water separation, and the solid residue enters the biochemical treatment device for treatment; among them, the biochemical treatment In the device, the microbial agent is put into the feeding port of the fermenter, and heated and intermittently stirred in the fermenter, the heating temperature is controlled at 60°C, and the stirring speed is 80 rpm; the microbial agent is made of Composed of actinomycetes, lactic acid bacteria, yeast and photosynthetic bacteria, which are added i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com