Straw compost after-ripening enzyme accelerator and use method therefor

A technology of enzyme accelerator and straw, which is applied in the field of straw composting enzyme accelerator, can solve the problems that the decomposing process is difficult to work, endangers human health, and the effect is not obvious enough, so as to improve the germination rate of seeds, promote crop growth, and reduce biological toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

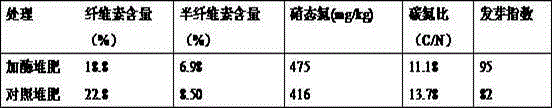

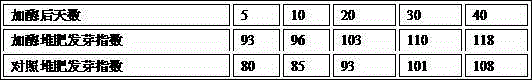

Embodiment 1

[0024] The cellulase used is cellulase produced by Trichoderma, origin: Beijing. Carboxymethylcellulase activity is 1,034 U g -1 . The optimum working temperature is 40-50 C. The protease used is AS1.398 neutral protease ( Bacillus subtilis neutral protease). The exogenous protease activity is 58,820 U g -1 . The optimum temperature for exogenous protease is 35-45 C.

[0025] The straw used is rice straw, which comes from the paddy fields of Wujing Town, Minhang District, Shanghai.

[0026] Composting:

[0027] (1) Two groups of straw compost were set up, one group was the enzyme-added compost to be added with post-ripening enzyme accelerator, and the other was the control compost without adding post-ripening enzyme accelerator. Each group of straw composting was firstly subjected to conventional composting treatment: the straw was cut into small pieces less than 5 cm, mixed according to the ratio of 150 kg of straw and 300 kg of water, stacked outdoors, and covered wi...

Embodiment 2

[0041] The cellulase used is the cellulase produced by Trichoderma. Carboxymethylcellulase activity at 1,000 U g -1 , the optimum temperature is 40-50 C. The protease used is AS1.398 neutral protease ( Bacillus subtilis neutral protease). The exogenous protease activity is 50000 U g -1 . The optimum temperature for exogenous protease is 35-45 C.

[0042] The straw used is wheat straw, which comes from the wheat field in Pancheng Town, Pukou District, Nanjing.

[0043] Composting:

[0044] (1) Two groups of straw compost were set up, one group was the enzyme-added compost to be added with post-ripening enzyme accelerator, and the other was the control compost without adding post-ripening enzyme accelerator. Each group of straw composting was firstly subjected to conventional composting treatment: the wheat straw was crushed into small pieces less than 5 cm, mixed according to the ratio of 100 kg of straw and 200 kg of water (moisture content about 67%), stacked outdoors,...

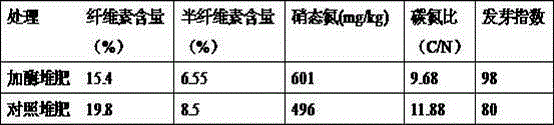

Embodiment 3

[0056] The cellulase used is the cellulase produced by Trichoderma. Carboxymethylcellulase activity at 1,000 U g -1 , the optimum temperature is 40-50 C. The test protease is AS1.398 neutral protease ( Bacillus subtilis neutral protease). The exogenous protease activity is 50000 U g -1 . The optimum temperature for exogenous protease is 35-45 C.

[0057] The straw used in the test was corn straw, which came from the wheat-corn rotation area of Bincheng District, Binzhou City.

[0058] Chinese cabbage ( Brassica chinensis L. ) seeds (variety: Shanghai Qing; place of origin: Shanghai).

[0059] Composting:

[0060] (1) Two groups of straw compost were set up, one group was the enzyme-added compost to be added with post-ripening enzyme accelerator, and the other was the control compost without adding post-ripening enzyme accelerator. Each group of straw composting is firstly subjected to conventional composting treatment: crush corn straw into small pieces of about 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com