Method for producing greening substrate through rapid composting of dredged sediment

A technology for dredging sediment and greening substrates, applied to chemical instruments and methods, sewage/sludge fertilizers, nitrogen fertilizers, etc., can solve the problems of high pH value of solidified soil, high hardness of solidified soil, unsuitable for plant growth, etc., to achieve corrosion The effect of low requirements, high liquid phase viscosity, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

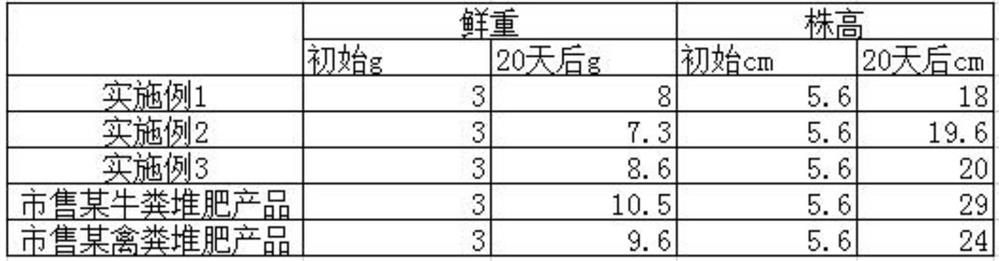

Embodiment 1

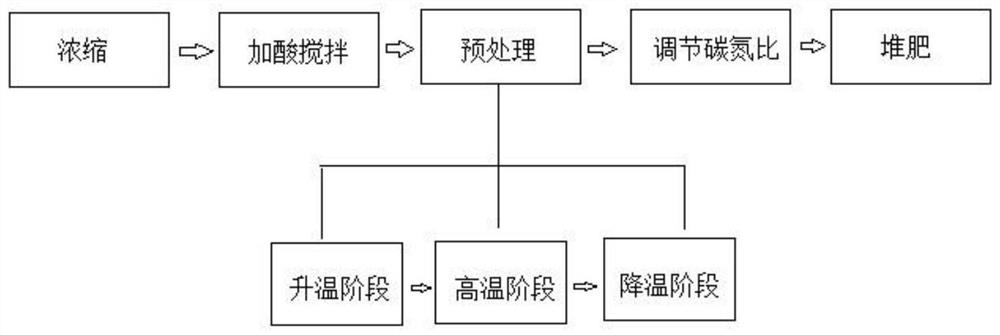

[0051] A method for dredging bottom mud to quickly compost to produce green substrates, comprising the following steps:

[0052] S1 is concentrated, and the dredged bottom mud is concentrated to a water content of 90%; S2 is added with acid and stirred, and 3 parts of acid are added to the concentrated mud in S1, and the stirring time is 10 minutes; the acid includes oxalic acid. S3 pretreatment, then add 2 parts of iron salt and 10 oxidants, fully stir, the stirring time is 10 minutes, then add garden waste, cow dung and fully stir, the stirring time is 30 minutes, adjust the pH value in the sludge to 6.5; at 1m 3 Add 25kg of the mixture of iron salt and oxidant to the concentrated mud in the above S1. The oxidizing agent includes liquid ozone with a mass concentration of 35%. The iron salt includes iron oxide. S4 adjusts the carbon-nitrogen ratio and mixes the stockpiles to 1m 3 Add 8 parts of metal passivator modified zeolite and modified sepiolite to the pile body, mix...

Embodiment 2

[0060] A method for dredging bottom mud to quickly compost to produce green substrates, comprising the following steps:

[0061] S1 concentration, the dredged sediment is concentrated to a water content of 97%;

[0062] Add acid and stir in S2, add 5 parts of acid to the concentrated mud in S1, and stir thoroughly for 130 minutes; the acid includes oxalic acid.

[0063] S3 pretreatment, then add 6 parts of iron salt and 12 oxidants, fully stir, the stirring time is 30 minutes, then add garden waste, cow dung and fully stir, the stirring time is 60 minutes, adjust the pH value in the sludge to 7.3; at 1m 3 Add 10kg of the mixture of iron salt and oxidant to the concentrated mud in the above S1. The oxidizing agent includes liquid ozone with a mass concentration of 35%. The iron salt includes iron oxide.

[0064] S4 adjusts the carbon-nitrogen ratio and mixes the stockpiles to 1.5m 3 Add 1 part of metal passivator modified zeolite and modified sepiolite to the pile, mix eve...

Embodiment 3

[0072] A method for dredging bottom mud to quickly compost to produce green substrates, comprising the following steps:

[0073] S1 concentration, the dredged sediment is concentrated to a water content of 96%;

[0074] Add acid and stir in S2, add 4 parts of acid to the concentrated mud in S1, and stir thoroughly for 20 minutes; the acid includes oxalic acid.

[0075] S3 pretreatment, then add 3 parts of iron salt and 11 oxidants, fully stir, the stirring time is 20 minutes, then add garden waste, cow dung and fully stir, the stirring time is 45 minutes, adjust the pH value in the sludge to 7; at 1m 3 Add 21kg of the mixture of iron salt and oxidant to the concentrated mud in the above S1. The oxidizing agent includes liquid ozone with a mass concentration of 32%. The iron salt includes iron oxide.

[0076] S4 adjusts the carbon-nitrogen ratio and mixes the stockpiles to 1.2m 3 Add 7 parts of metal passivator modified zeolite and modified sepiolite to the pile body, mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com