Preparation method for obtaining uniform xylan from corn cob

A technology of xylan and corn cob, which is applied to the preparation of sugar derivatives, oligosaccharides, chemical instruments and methods, etc., and can solve problems such as no patents yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

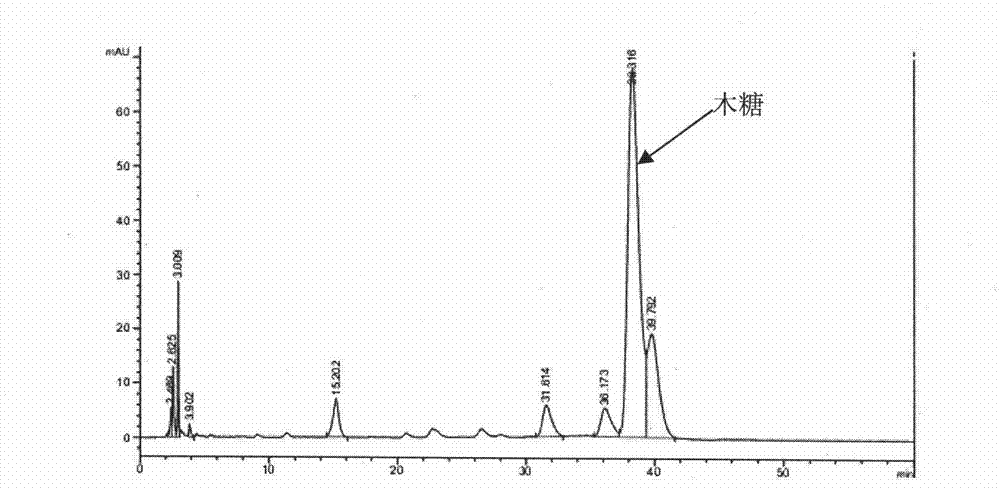

Embodiment 1

[0020] (1) Select fresh, moth-eaten, and mildew-free corn cobs, and after drying, smash them into small pieces with a hammer, dry them, and put them in a grinder to crush them. The crushed corn cob powder is passed through a 20-mesh sieve for subsequent use.

[0021] (2) Weigh 80 g of corncob powder (larger particles), add distilled water at a solid-to-liquid ratio of 1:8, heat-treat in a water bath at 90°C for 1 hour, and filter out the liquid with nylon gauze.

[0022] (3) Add 1200mL 10g / 100mL NaOH solution to the remaining solid, stir and extract at 80°C for 2h, after the solution is cooled, adjust the pH to 7.7 with HCL, centrifuge at 8000rpm / min for 10min, and obtain the precipitate and supernatant respectively.

[0023] (4) The supernatant was concentrated by rotary evaporation, and 95% ethanol was added to make the final concentration 80%, and alcohol precipitation was carried out overnight. Centrifuge at 8000rpm / min for 10min to collect the precipitate, and then redis...

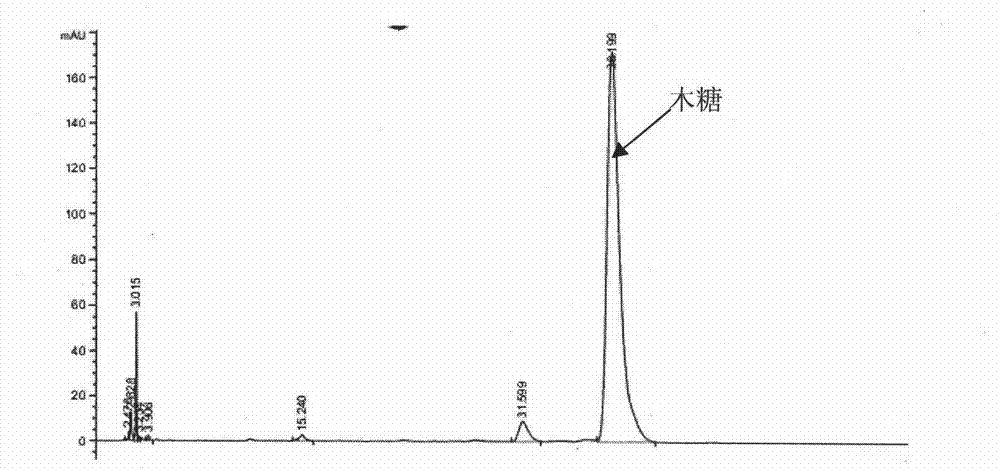

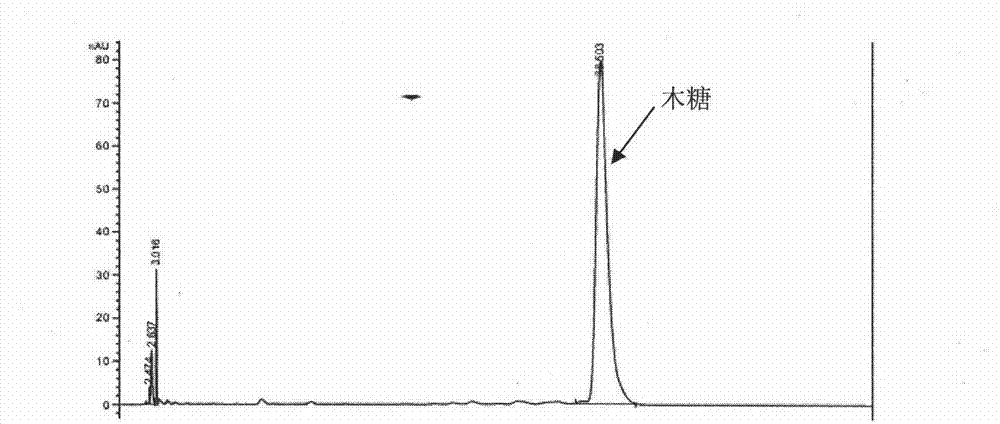

Embodiment 2

[0029] (1) Select fresh, moth-eaten, and mildew-free corn cobs, and after drying, smash them into small pieces with a hammer, dry them, and then place them in a grinder for crushing. The crushed corn cob powder is passed through a 20-mesh sieve for subsequent use.

[0030] (2) Weigh 20 g of corncob powder, add distilled water at a solid-to-liquid ratio of 1:6, heat-treat in a water bath at 80° C. for 1 hour, and filter out the liquid with nylon gauze.

[0031] (3) Add 300mL 10g / 100mL NaOH solution to the remaining solid, stir and extract at 80°C for 2h, after the solution is cooled, filter it with nylon gauze, adjust the pH of the filtrate to 5.8 with anhydrous acetic acid, add 95% ethanol, the final concentration is 50%, alcohol precipitation overnight. Centrifuge at 8000rpm / min for 10min to collect the precipitate. After rehydration (solid-to-liquid ratio 1:15, 60°C, 2h), centrifuge at 8000rpm / min for 10min to obtain supernatant A and precipitate B.

[0032] (4) Precipitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com