Method for synchronously determining monosaccharide, uronic acid and saccharic acid in wood fiber material reaction system

A technology of lignocellulosic raw materials and reaction systems, which is applied in the directions of measuring devices, material separation, and analysis of materials, etc., can solve the problem that it is difficult to distinguish the mutual interference of various sugar acids and uronic acids, the inaccurate determination of sugar acids and uronic acids, and the sensitivity Low-level problems, achieve good economic benefits and social effects, improve separation and detection efficiency, and achieve rapid qualitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

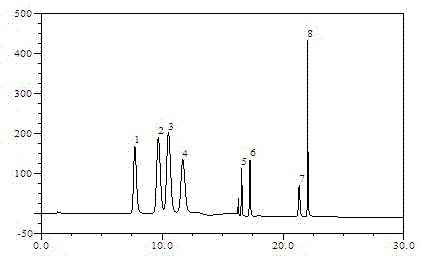

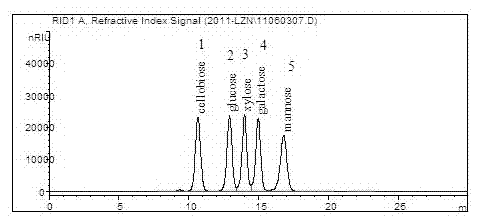

[0033] High performance liquid phase ion exchange chromatography system: American Dionex ICS-3000 ion chromatography system, equipped with double pump (DP) built-in vacuum degassing module, electrochemical detector (ED) and automatic sampler (AS40), operating software of chromatography system Chromeleon 6.70 chromatographic workstation was used; chromatographic conditions: chromatographic column: CarboPacTM PA10 (2×250mm) chromatographic column with guard column (2×50mm), column temperature: 30°C; injection volume: 10.0 μL;

[0034] Elution conditions: Binary gradient elution with 18mmol / L sodium hydroxide, 200mmol / L sodium hydroxide and 500mmol / L sodium acetate as the eluent, the flow rate is 0.3mL / min, and 18mmol / L L sodium hydroxide solution for isocratic elution; the concentration gradient of sodium acetate solution elution within 10-20min is 50-200mmol / L, and the concentration gradient of sodium hydroxide solution elution is 65.4-70.8mmol / L; 20-40min The concentration of ...

Embodiment 2

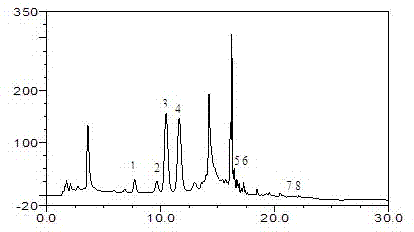

[0060] The lignocellulosic raw material was subjected to steam explosion (200°C, 5.0min) and enzymatic hydrolysis (substrate mass concentration 10%, cellulase dosage 3.0FPIU / g cellulose, xylanase dosage 100IU / g xylan, stirred at 50°C Reaction 24h) After the biorefining process, the sample solution of the reaction system was obtained, the sample solution to be tested was fully dissolved in distilled water at 25-30°C, the volume was fixed and the concentration of the xylo-oligosaccharide component to be tested was adjusted to 0.1-10.0 mg / L, centrifugal 5min under the condition of 10000rpm, filter the supernatant liquid with 0.2 μm microfiltration membrane to obtain sample liquid, transfer to the high performance liquid phase ion exchange chromatography system of embodiment 1 again, adopt CarboPacTM PA10 (2 * 250mm) chromatographic column , the column temperature is 30°C, the injection volume is 10.0 μL, and the binary gradient elution is carried out with 18mmol / L sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com