Preparation method of modified tobacco extracts

A tobacco extract and extract technology, applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problem of few varieties of tobacco extracts, achieve excellent stability and repeatability, increase the richness of aroma, and the aroma is realistic and natural Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

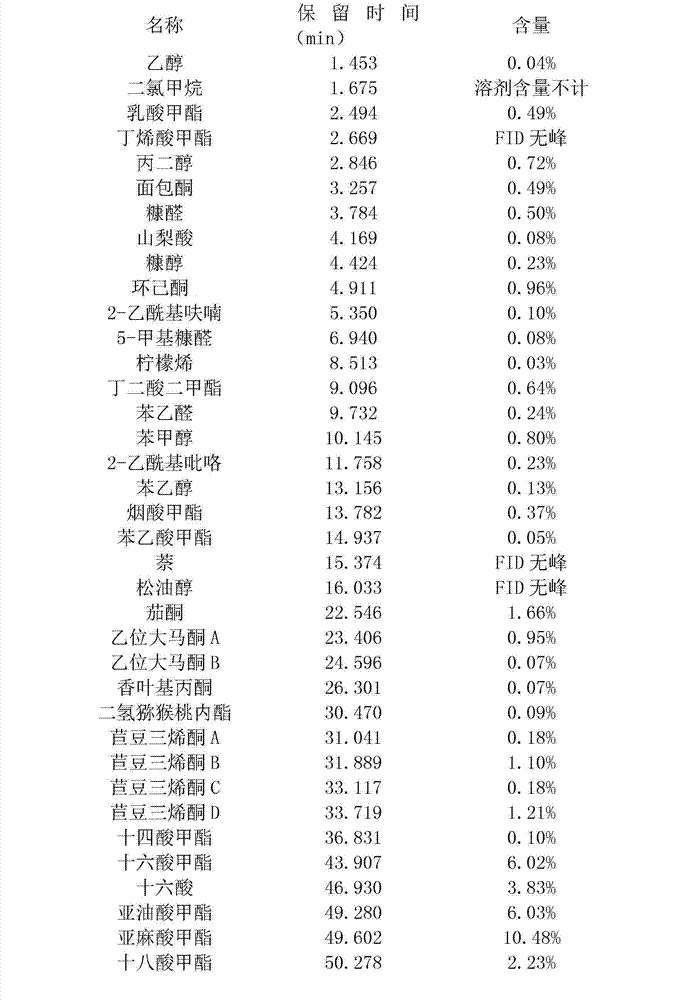

Image

Examples

preparation example Construction

[0022] The present invention provides a kind of preparation method of modified tobacco extract, comprising the following steps:

[0023] (1) Subcritical extraction: Precisely weigh 1KG of crushed tobacco leaf powder (equivalent to 1 / 30 of the volume of the extraction column), put it into an extraction column of about 1.0 mL, put the extraction column into a constant temperature box, and use an infusion pump to Pump the mixed extractant in constant pressure mode, under the conditions of temperature at 120°C, 140°C, 160°C, 180°C, 200°C, 220°C and pressure at 5, 7, 11, 13, 15, 17 and 19MPa Extract to obtain tobacco volatile aroma substance A and tobacco extract B.

[0024] (2) Organic extraction and concentration: Add absolute ethanol to the tobacco extract B, and reflux the condenser tube for extraction. The extraction time is 4hr. After extraction, the extract is concentrated again with a thin film evaporator that can continuously feed, and the evaporation condition is The con...

Embodiment 1

[0028] Crush the tobacco fragments to 50-100 mesh, accurately weigh 1Kg of tobacco leaf powder, put it into an extraction column, put the extraction column into a constant temperature box, and add 4Kg of extractant water with an infusion pump in constant pressure mode. Extract at 120°C and 5MPa pressure. Tobacco volatile aroma substance A and extract B were obtained.

[0029] Organic extraction and concentration: Add absolute ethanol to the extract B until the ethanol concentration is 30%, reflux extraction in the condenser tube, the extraction time is 4hr, after extraction, the extract is concentrated with a thin film evaporator that can be continuously fed, evaporated The condition is that the condensation temperature is 10°C and the heating temperature is 45°C. After repeated concentration, the extract can be concentrated to a target concentration of 35%.

[0030] Biochemical reaction: Weigh 20g of the concentrated extract, add 40g of high fructose syrup, 10g of glucose sy...

Embodiment 2

[0033] Crush the tobacco fragments to 50-100 mesh, accurately weigh 1Kg of tobacco leaf powder, put it into an extraction column, put the extraction column into a constant temperature box, and add 4kg of extractant water with an infusion pump in a constant pressure mode. Extract at 220°C and 19MPa pressure. Tobacco volatile aroma substance A and extract B were obtained.

[0034] Organic extraction and concentration: Add absolute ethanol to the extract B until the ethanol concentration is 50%, and reflux the condenser tube for extraction. The extraction time is 2.5hr. The condition is that the condensation temperature is 10°C and the heating temperature is 45°C. After repeated concentration, the extract can be concentrated to a target concentration of 35%.

[0035] Biochemical reaction: Weigh 20g of extract, 30g of high fructose syrup, 20g of Umle extract, 20g of propylene glycol, and 10g of water; heat to 115°C; stir and react for 2 hours; reaction.

[0036] The modified to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com