Manufacturing method for high temperature-resistant high-strength flexible graphite material

A technology of flexible graphite materials and manufacturing methods, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of loss of compression resilience and stress relaxation rate of sealing properties, poor mechanical strength of flexible graphite materials, affecting applications and other problems, to achieve the effect of saving the drying step, saving the process, and enhancing the blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

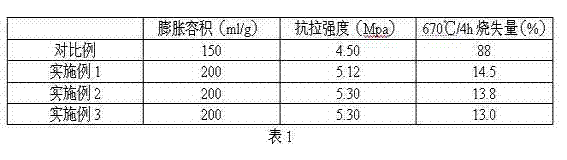

Examples

preparation example Construction

[0021] Preparation of expandable graphite: Add 1000kg of 80 mesh natural flake graphite with a fixed carbon content of 95% in the reaction kettle, add 150kg of ammonium nitrate particles, stir and mix evenly, then add 2000kg of 98% concentrated sulfuric acid, stir for 10 minutes, and then add 500kg of 98% concentrated sulfuric acid was stirred and reacted for 45 minutes. Let the reacted graphite self-flow to the hanging bag centrifugal dehydrator for deacidification for 20 minutes, take out the deacidified graphite and add it to water filled with about 5m3, stir and soak for about 5-10 minutes, and then dehydrate through the centrifugal dehydrator to obtain expanded graphite.

[0022] The preparation method of expandable graphite provided above is only for a clearer and intuitive description of the present invention.

Embodiment 1

[0024] A method for manufacturing a high-temperature resistant high-strength flexible graphite material, specifically comprising the following steps:

[0025] 1) Preparation of additives: Take 12g of phosphoric acid, 8g of aluminum dihydrogen phosphate, 2g of boric acid and 20g of triethyl phosphate, add 400g of water to make an additive solution;

[0026] 2) Add 400g of the above-mentioned expandable graphite into the solution prepared in step 1), soak for 30min;

[0027] 3) Filter the material after soaking, rinse the expandable graphite with the obtained filtrate, repeat twice, suction filter to make the liquid content in the expandable graphite 20% of the total weight, and then dry the expandable graphite to change permanent expandable graphite;

[0028] 4) The modified expandable graphite is expanded and rolled to form a flexible graphite material with high temperature resistance and high strength.

Embodiment 2

[0030] A method for manufacturing a high-temperature resistant high-strength flexible graphite material, specifically comprising the following steps:

[0031] 1) Preparation of additives: Take phosphoric acid, calcium dihydrogen phosphate, boric acid and tributyl phosphate, and add water to make an additive solution. The mass fractions of phosphoric acid, calcium dihydrogen phosphate, boric acid and tributyl phosphate in the solution are 5% respectively. 30%, 1.5%, 10%. ;

[0032] 2) Add the above additive solution to 100g of expandable graphite, immerse the expandable graphite for 20min,

[0033] 3) Filter the soaked material, rinse the expandable graphite with the obtained filtrate, repeat twice, and suction filter to make the liquid content in the expandable graphite 25% of the total weight, and then dry the expandable graphite to change permanent expandable graphite;

[0034] 4) The modified expandable graphite is expanded and rolled to form a flexible graphite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com