Method for removing sulfides in MTBE by adsorptive distillation

An adsorption distillation, sulfide technology, applied in organic chemistry, ether separation/purification, ether preparation, etc., can solve problems such as MTBE loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

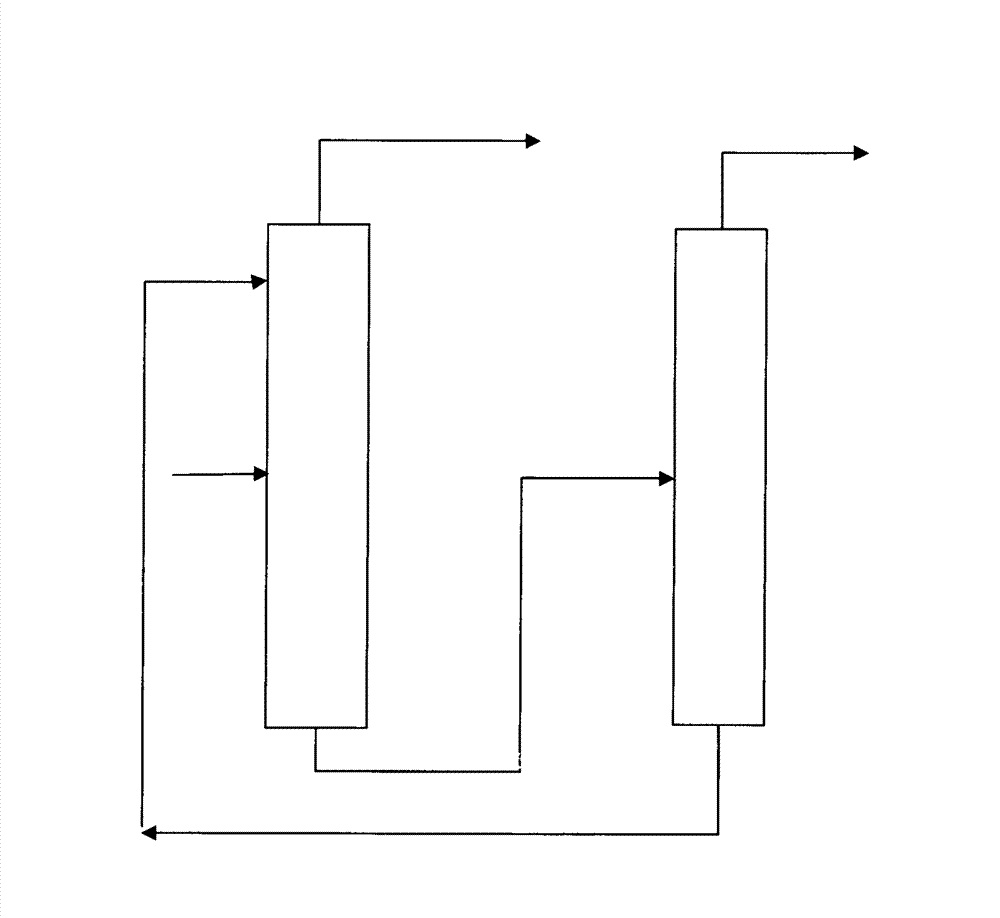

Method used

Image

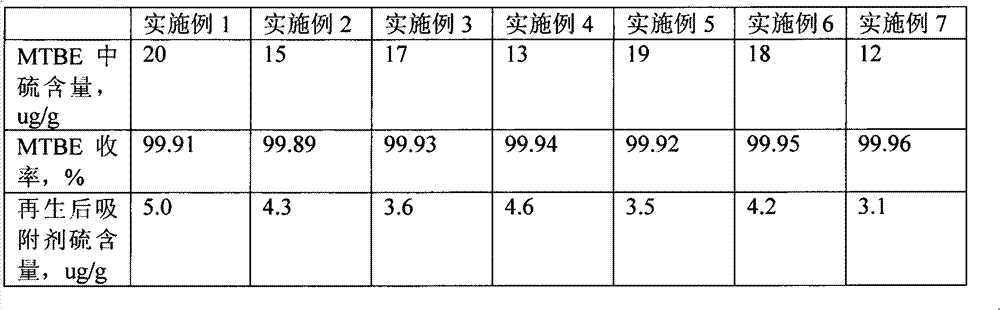

Examples

Embodiment 1

[0019] MTBE desulfurization is carried out in an adsorption distillation tower (theoretical plate number is 35) that is 30 millimeters in diameter and 600 millimeters high with ceramic Raschig rings as packing. First in the catalytic distillation tower, the filling height is the first adsorbent that is furnished with 0.1% benzoyl peroxide activator at 100 millimeters, then the tower still temperature is raised to 70 ℃, from the stripping section of the adsorption distillation tower by the rate of 80g / h The speed is to pump MTBE into the adsorption distillation tower through the metering pump, and the MTBE feed temperature is 80°C;

[0020] The adsorbent formamide is pumped into the adsorption distillation tower from the top of the tower by the metering pump at a speed of 40g / h, and the temperature at the top of the tower is maintained at 60°C; The adsorbent is pumped into the lower part of the adsorbent regeneration tower, and the temperature of the adsorbent regeneration towe...

Embodiment 2

[0022] MTBE desulfurization is carried out in an adsorption distillation tower (35 theoretical plates) with a diameter of 30 mm and a height of 600 mm and ceramic Raschig rings as fillers. First in the catalytic distillation tower, the filling height is the second adsorbent that is equipped with 0.3% methyl ethyl ketone peroxide activator, then the temperature of the tower bottom is raised to 80 ° C, and the stripping section of the adsorption distillation tower is passed through at a speed of 80 g / h The metering pump pumps MTBE into the adsorption distillation tower, and the MTBE feed temperature is 90°C; the second adsorbent is pumped into the adsorption distillation tower from the top of the tower through the metering pump at a speed of 60g / h, and the temperature at the top of the tower is maintained at 55°C; Pump the sulfur-containing adsorbent into the lower part of the adsorbent regeneration tower through the metering pump at a rate of 60g / h in the distillation column, an...

Embodiment 3

[0024] MTBE desulfurization is carried out in an adsorption distillation tower (35 theoretical plates) with a diameter of 30 mm and a height of 600 mm and ceramic Raschig rings as fillers. At first in the catalytic distillation tower, the filling height is the acetone adsorbent that is equipped with 0.2% cyclohexanone peroxide activator at 100 millimeters, then the tower still temperature is raised to 85 ℃, from the stripping section of the adsorption distillation tower by the rate of 90g / h The speed is to pump MTBE into the adsorption distillation tower through the metering pump, and the MTBE feed temperature is 85°C; the propane adsorbent is pumped into the adsorption distillation tower from the top of the tower through the metering pump at a speed of 70g / h, and the temperature at the top of the tower is maintained at 65°C; The sulfur-containing adsorbent is pumped into the lower part of the adsorbent regeneration tower through the metering pump at a rate of 70g / h from the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com