Engine lubricating oil

A technology for lubricating oil and engine, applied in the field of lubricating oil, can solve the problems of high exhaust temperature of engine, volatile lubricating oil, short lubricating oil life, etc., to achieve excellent acid neutralization ability, outstanding anti-wear performance, excellent anti-wear performance performance and effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

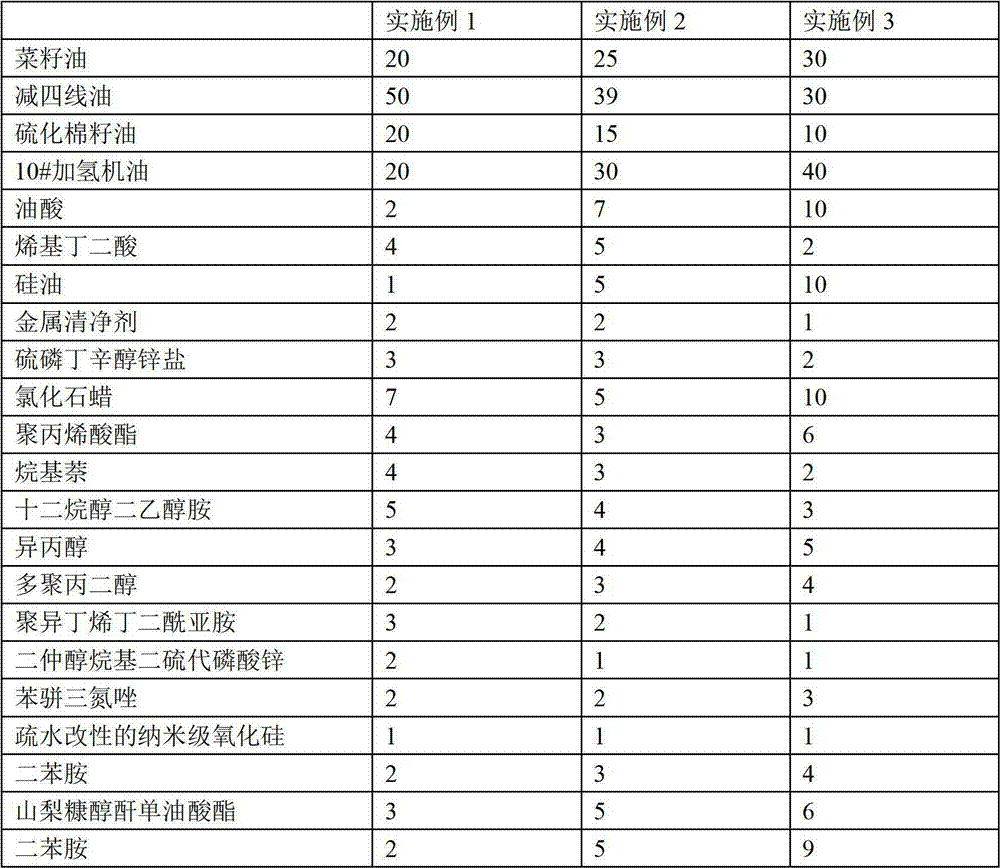

preparation example Construction

[0023] The preparation method of the above-mentioned hydrophobically modified nano-scale silicon oxide is: the nano-scale silicon oxide is soaked in the silane coupling agent KH-570.

[0024] The preparation method of above-mentioned engine lubricating oil is:

Embodiment 1

[0026] S1: Add rapeseed oil and four-line oil to the reaction kettle, heat to 60°C, and stir for 1 hour;

[0027] S2: add vulcanized cottonseed oil, 10# hydrogenated engine oil, oleic acid, alkenyl succinic acid, silicone oil, calcium petroleum sulfonate, zinc salt of thiophosphobutanol, benzotriazole, hydrophobically modified nano-scale oxidation Silicon, heated to 70°C, stirred for 0.5h, cooled to 50°C

[0028] S3: Add chlorinated paraffin, polyacrylate, alkylnaphthalene, dodecanol diethanolamine, isopropanol, polypropylene glycol, polyisobutylene succinimide, sorbitan monooleate, diphenylamine, in Stir at 50 °C for 1 h.

Embodiment 2

[0030] The difference from Example 1 is: in step S1, the temperature is 65°C; in step S2, the temperature is heated to 75°C and cooled to 55°C; in step S3, the temperature is 55°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com