Zirconium micro-alloyed nickel-aluminum bronze

A nickel-aluminum bronze and micro-alloying technology is applied to nickel-aluminum bronze alloy and its preparation, zirconium microalloyed nickel-aluminum bronze and its preparation field, can solve problems such as restricting high-speed development, and achieve the reduction of friction coefficient and the reduction of friction coefficient. Low, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

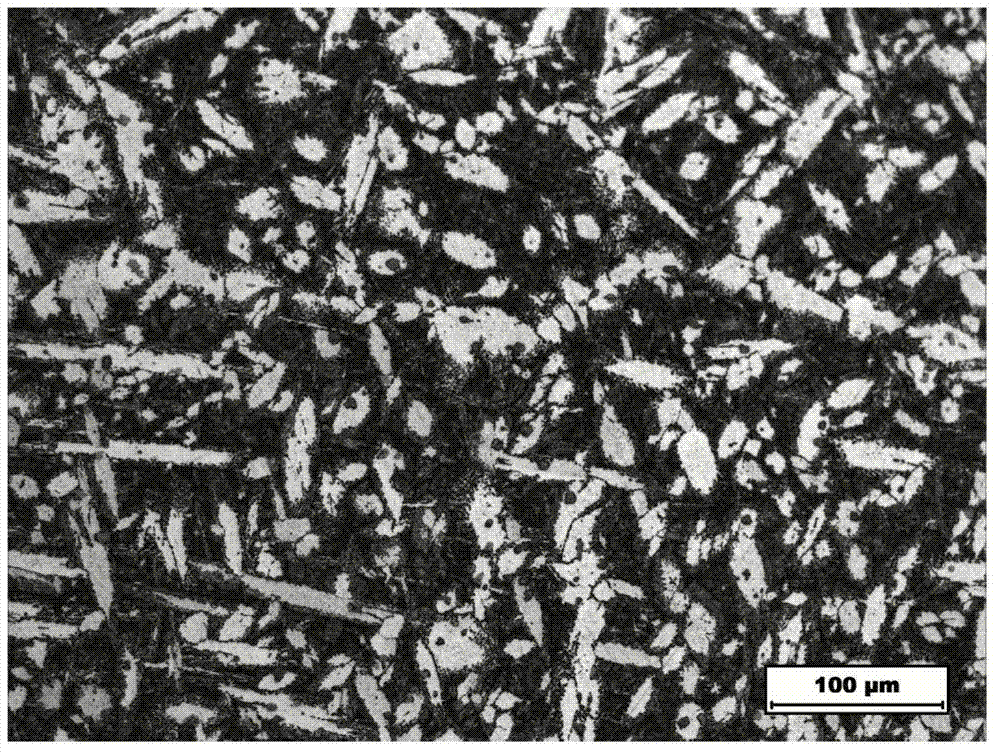

[0022] Such as figure 1 shown.

[0023] A zirconium microalloyed nickel-aluminum bronze, the preparation method of which is:

[0024] Take 8.9577kg as an example.

[0025] First, 8.85kg of self-made (see comparative example 1) or commercially available nickel-aluminum bronze (composition: 79.77Cu, 1.1Mn, 8.84Al, 5.05Fe, 4.54Ni, 0.58Zn, the numbers before all element symbols in the examples represent Mass percentage, the same below) After melting, add 107.7g Al-Zr master alloy (95.69%Al, 4.11%Zr (the content of zirconium is preferably 3.699~4.521%), 0.20%Fe, 0.10%Si ) (the loss rate of Zr about 8%), the master alloy can be purchased directly from the market, or can be self-prepared by conventional methods; after it is completely melted, add a slag remover (to remove impurities), and then pass into high-purity nitrogen for refining for 3 minutes; finally , poured into the ladle, and after standing for 1-5 minutes, the slag was removed and cast into an ingot; that is, a zircon...

Embodiment 2

[0029] A zirconium microalloyed nickel-aluminum bronze, the preparation method of which is:

[0030] Take 8.9577kg as an example.

[0031] First, melt 8.855kg of nickel-aluminum bronze (composition: 78.34Cu, 1.30Mn, 9.94Al, 5.52Fe, 4.30Ni, 0.43Zn, the numbers before all element symbols in the examples represent mass percentages, the same below) and add 102.7 g Al-Zr master alloy (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si) (the loss rate of Zr is about 8%), described master alloy can be purchased directly from the market, also can adopt conventional The method is self-prepared; after it is completely melted, add a slag remover (to remove impurities), and then pass high-purity nitrogen to refine for 3 minutes; finally, pour it into a ladle, keep it for 1-5 minutes, remove the slag and cast it into an ingot; that is A zirconium microalloyed nickel aluminum bronze is obtained.

[0032] The nickel-aluminum bronze after microalloying of zirconium in this embodiment is actually measured ...

Embodiment 3

[0034] A zirconium microalloyed nickel-aluminum bronze, the preparation method of which is:

[0035] Take 8.9577kg as an example.

[0036] First, 8.887kg of self-made (see comparative example 1) or commercially available nickel-aluminum bronze (composition: 79.77Cu, 1.1Mn, 8.84Al, 5.05Fe, 4.54Ni, 0.58Zn, the numbers before all element symbols in the examples represent Mass percentage, the same below) After melting, add 71.07g Al-Zr master alloy (95.69%Al, 4.11%Zr (the content of zirconium is preferably 3.699~4.521%), 0.20%Fe, 0.10%Si ) (loss rate of Zr about 8%), the master alloy can be purchased directly from the market, or can be self-prepared by conventional methods; after it is completely melted, add a slag remover (to remove impurities), and then pass into high-purity nitrogen for refining for 3 minutes; finally , poured into the ladle, and after standing for 1-5 minutes, the slag was removed and cast into an ingot; that is, a zirconium microalloyed nickel-aluminum bronz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com