Electrochemical method for preparing hydroxyapatite dendritic micro nano composite coating on surface of metallic titanium

A hydroxyapatite, micro-nano composite technology, applied in the field of biomedical materials, can solve the problems of low solubility, slow integration rate, etc., and achieve easy adsorption, easy operation, and excellent combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

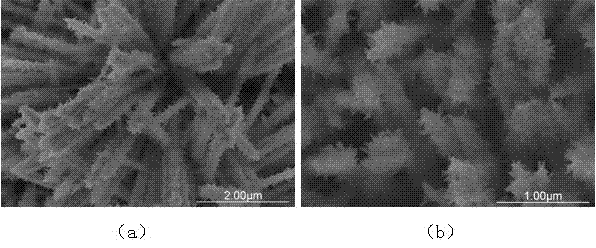

Embodiment 1

[0030] 1) Add molar concentration of 1.2mMCaCl 2 , the molar concentration is 0.72mMNH 4 h 2 PO 4 , The molar concentration is 0.1MNaCl mixed, the pH value of the electrolyte is adjusted to 6 with ammonia water or hydrochloric acid solution, heated to 85°C and then kept at a constant temperature to obtain a low-concentration Ca-P electrolyte;

[0031] 2) Add molar concentration of 9.6mMCaCl 2 , the molar concentration is 5.76mM NH 4 h 2 PO 4 , molar concentration is 0.1MNaCl, molar concentration is 38.4mM Na 3 Mix with Cit, adjust the pH value of the electrolyte to 6 with ammonia water or hydrochloric acid solution, heat to 60°C and keep the temperature to obtain a high-concentration Ca-P electrolyte;

[0032] 3) Platinum is used as the anode, and the metal titanium substrate is used as the cathode. The anode and the cathode are completely immersed in the low-concentration Ca-P electrolyte. The DC voltage between the two electrodes is set to -3.0V, and the distance betw...

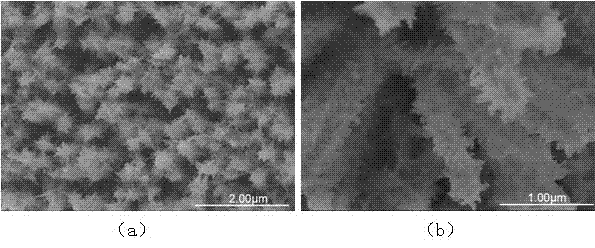

Embodiment 2

[0036] 1) Add molar concentration of 0.6mMCaCl 2 , the molar concentration is 0.36mMNH 4 h 2 PO 4 , The molar concentration is 0.1MNaCl mixed, the pH value of the electrolyte is adjusted to 6 with ammonia water or hydrochloric acid solution, heated to 85°C and then kept at a constant temperature to obtain a low-concentration Ca-P electrolyte;

[0037] 2) Add molar concentration of 2.4mMCaCl 2 , the molar concentration is 1.44mM NH 4 h 2 PO 4 , molar concentration is 0.1MNaCl, molar concentration is 1.2mM Na 3 Mix with Cit, adjust the pH value of the electrolyte to 6 with ammonia water or hydrochloric acid solution, heat to 60°C and keep the temperature to obtain a high-concentration Ca-P electrolyte;

[0038] 3) Platinum is used as the anode, and the metal titanium substrate is used as the cathode. The anode and the cathode are completely immersed in the low-concentration Ca-P electrolyte. The DC voltage between the two electrodes is set to -3.0V, and the distance betwe...

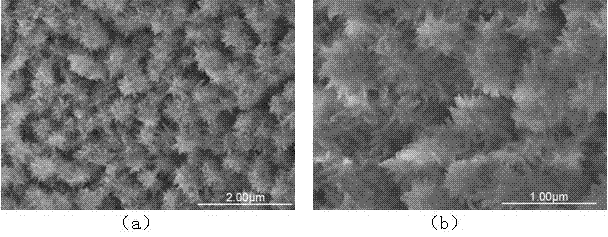

Embodiment 3

[0042] 1) Add molar concentration of 0.9mMCaCl 2 , the molar concentration is 0.54mMNH 4 h 2 PO 4 , The molar concentration is 0.1MNaCl mixed, the pH value of the electrolyte is adjusted to 6 with ammonia water or hydrochloric acid solution, heated to 85°C and then kept at a constant temperature to obtain a low-concentration Ca-P electrolyte;

[0043] 2) Add molar concentration of 6mMCaCl 2 , the molar concentration is 3.6mM NH 4 h 2 PO 4 , molar concentration is 0.1MNaCl, molar concentration is 24mM Na 3 Mix with Cit, adjust the pH value of the electrolyte to 6 with ammonia water or hydrochloric acid solution, heat to 60°C and keep the temperature to obtain a high-concentration Ca-P electrolyte;

[0044] 3) Platinum is used as the anode, and the metal titanium substrate is used as the cathode. The anode and the cathode are completely immersed in the low-concentration Ca-P electrolyte. The DC voltage between the two electrodes is set to -3.0V, and the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com