Potentilla discolor extract for reversing multidrug resistance of tumor, preparation method and application of potentilla discolor extract

A multi-drug resistance and extract technology, which is applied in the direction of anti-tumor drugs, drug combinations, pharmaceutical formulations, etc., to achieve the effect of reversing tumor multi-drug resistance, low drug cost, and simple production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

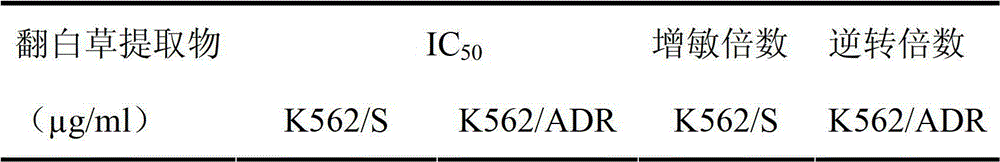

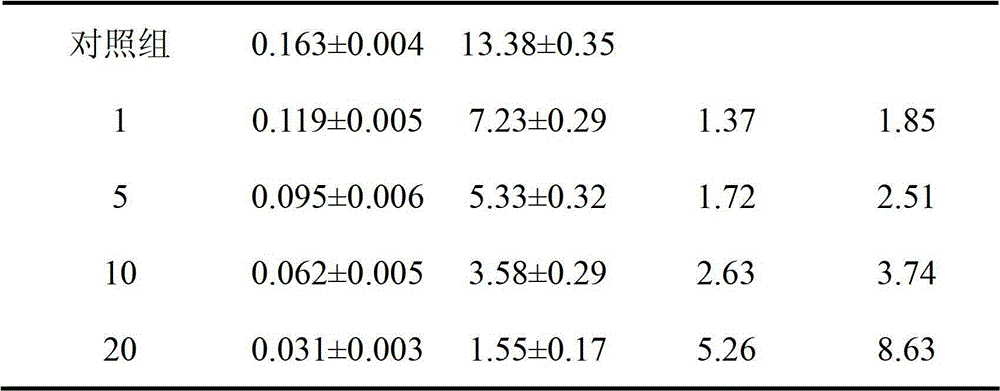

Image

Examples

Embodiment 1

[0022] 1 kg of Herba Vermilion, crushed, passed through a 40-mesh sieve, soaked with 2 times 90% ethanol for 1 day, filtered, collected the filtrate, recovered the ethanol and concentrated it to a viscous liquid, added 80% ethanol to dissolve it, and placed it at room temperature for 1 day. Wash and filter with 80% ethanol, collect the filtrate, and concentrate the filtrate to a relative density of 1.04g / cm 3 The filtrate concentrate was obtained, the filtrate concentrate was spray-dried, the air inlet temperature was controlled at 110° C., the outlet air temperature was 70° C., the atomizer rotating speed was 45 rpm, and the feed rate was 3ml / min. The multidrug-resistant tumor extract is pulverized and passed through a 150-mesh sieve to obtain a fine powder of the anti-tumor multidrug-resistant extract of Herba Verbacula; after the fine powder is mixed with conventional excipients, it is pressed into tablets to obtain Tablets of herbal extracts for reversing tumor multidrug r...

Embodiment 2

[0024] 1 kg of Herba Vermilion, crushed, passed through a 40-mesh sieve, soaked in 3 times 75% ethanol for 2 days, filtered, collected the filtrate, recovered the ethanol and concentrated it to a viscous liquid, added 70% ethanol to dissolve it, and placed it at room temperature for 2 days. Wash and filter with 70% ethanol, collect the filtrate, and concentrate the filtrate to a relative density of 1.03g / cm 3 The filtrate concentrate was obtained, the filtrate concentrate was spray-dried, the air inlet temperature was controlled to be 120° C., the outlet air temperature was 80° C., the atomizer rotating speed was 50 rpm, and the feed rate was 5ml / min. For the multi-drug resistant tumor extract, crush the extract and pass through a 100-mesh sieve to obtain the fine powder of the anti-tumor multi-drug resistant extract of Herba Verbacula; after the fine powder is mixed with conventional excipients, it is made into granules and packed into capsules , to obtain capsules containing...

Embodiment 3

[0026] 1 kg of Herba Verbacula, crushed, passed through a 40-mesh sieve, soaked in 5 times 55% ethanol for 3 days, filtered, collected the filtrate, recovered the ethanol and concentrated it to a viscous liquid, added 60% ethanol to dissolve it, and placed it at room temperature for 3 days. Wash and filter with 60% ethanol, collect the filtrate, and concentrate the filtrate to a relative density of 1.02g / cm 3 , to obtain the filtrate concentrate, the filtrate concentrate is spray-dried, the air inlet temperature is controlled to be 130°C, the outlet air temperature is 90°C, the atomizer rotating speed is 55 rev / min, and the feed rate is 6ml / min, to obtain P. The anti-tumor multidrug-resistant extract is pulverized and passed through a 200-mesh sieve to obtain the fine powder of the anti-tumor multidrug-resistant extract of Herba Verbaculae; after the fine powder is mixed with conventional auxiliary materials, it is prepared into granules to obtain Granules containing the extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com