Electric spark servo control method based on current pulse probability detection

A technology of current pulse and servo control, applied in circuits, manufacturing tools, electric processing equipment, etc., can solve problems such as over-feeding or under-feeding, affecting processing speed and quality, so as to prolong service life, reduce broken wires, The effect of improving processing speed and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] Using the traditional servo control method based on gap voltage, single crystal silicon was subjected to equal-thickness WEDM with the processing parameters shown in Table 1. The feed speed initially set is 80 μm / s. Due to the failure of the existing servo system, the system cannot automatically adjust the speed and can only feed at a constant speed (80 μm / s). Moreover, due to the existence of volume resistance and contact resistance, the existing system cannot accurately identify the short circuit state. When the electrode wire has been bent by the workpiece, the machine tool is still fed at a speed of 80 μm / s, causing serious deviation of the cutting trajectory. The final cut workpiece such as Figure 7 shown.

[0055] The EDM servo control method based on current pulse probability detection of the present invention is used instead, and the processing parameters shown in Table 1 are also used to perform equal-thickness wire EDM processing on single crystal silicon. ...

example 2

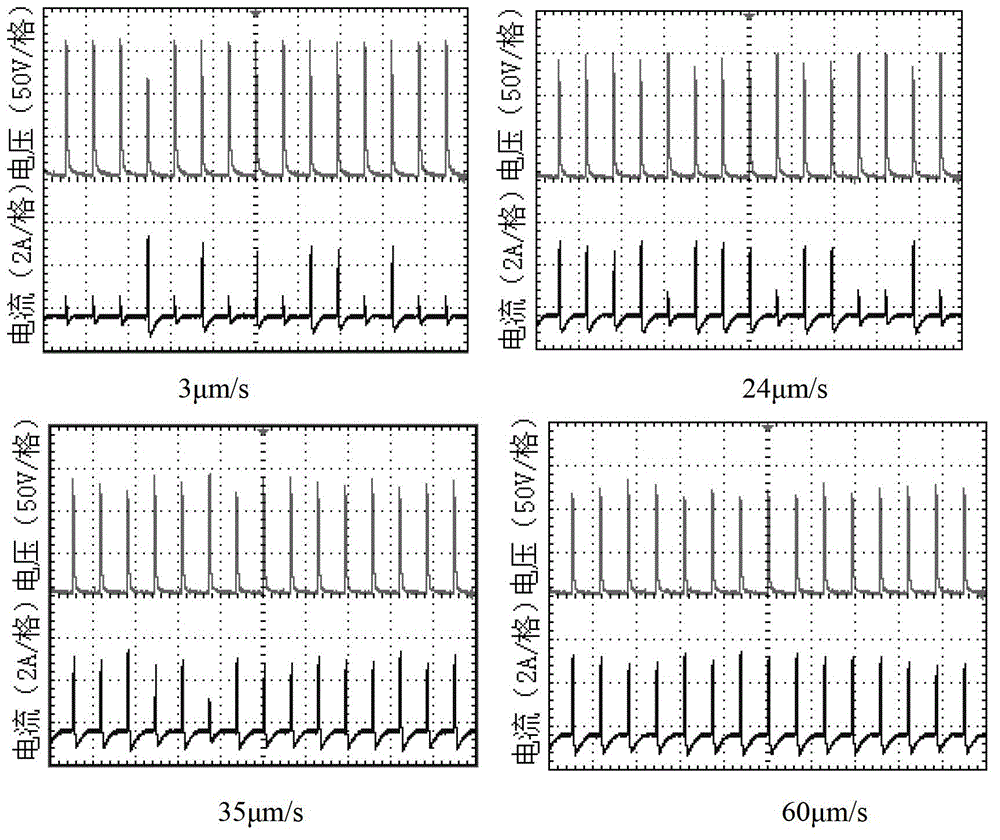

[0057] Using the traditional gap voltage-based servo control method, 45 steel was machined by WEDM with the processing parameters shown in Table 2. The initial maximum speed is set to 30μm / s. Since this speed is lower than the optimum processing speed during processing, the servo speed has been maintained at a high level of 28-29μm / s. However, due to the limitation of the maximum speed, the current speed can only be adjusted within the range of 0-30μm / s, which cannot reach the optimal processing speed. At this time, it is necessary to continuously adjust the maximum speed according to experience to achieve the best processing speed.

[0058] The electric discharge servo control method based on the current pulse probability detection of the present invention is used instead, and the processing parameters shown in Table 2 are also used to perform wire electric discharge processing on 45 steel. The current pulse probability is set to 95%. After the processing starts, the system ...

example 3

[0060] Using the EDM servo control method based on current pulse probability detection of the present invention, adopt the processing parameters shown in Table 1 to perform wire electric discharge processing with variable thickness on single crystal silicon, and set the current pulse probability to 70%. During the processing, as the thickness changes, the system continuously adjusts the feed rate to achieve the best feed rate for different thicknesses. The actual cutting picture is as follows Figure 9 As shown, the relationship between feed rate and thickness during processing is as follows Figure 10 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com