Method for producing high-sensitivity surface reinforcement Raman sensor chip

A surface-enhanced Raman and sensor chip technology, which is applied in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc., to achieve controllable coating, ensure uniformity, and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

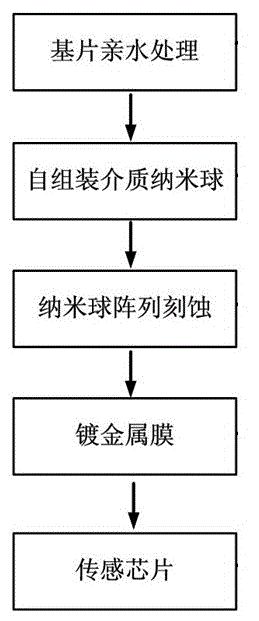

[0028] figure 1 It is a process flow diagram of the present invention, as shown in the figure, the highly sensitive surface-enhanced Raman sensor chip manufacturing method of the present invention comprises the following steps:

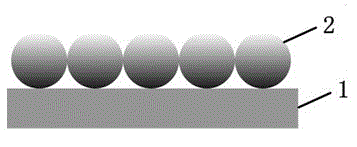

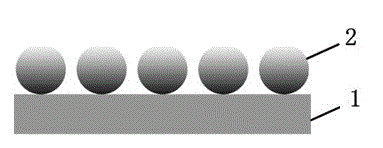

[0029] 1) Perform hydrophilic treatment on the substrate; the substrate is a quartz substrate, and the steps of hydrophilic treatment are: place the substrate in a solution prepared by concentrated sulfuric acid and hydrogen peroxide at a mass ratio of 3:1, heat at 80°C Bath for 1 hour, then take out the substrate, rinse it repeatedly with deionized water, and use ultrasonic vibration for 2 to 3 minutes; then place the substrate in a solution made of ammonia water, hydrogen peroxide and deionized water at a mass ratio of 1:1:5, Ultrasonic oscillation for 1 hour, then take out the substrate and rinse it with dei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com