Low-melting point glass powder for silver pastes on fronts of silicon solar cells and preparation method of glass powder

A silicon solar cell and low-melting glass technology, which is applied in the field of lead-free low-melting glass powder for front silver paste of crystalline silicon solar cells and its preparation, can solve the problem of the uniformity of anti-reflection film silver powder and silicon substrate without considering the particle size distribution. Focus on the influence of power and conductivity, without considering the influence of shadow absorption efficiency and conversion efficiency of contact grid lines and electrodes, and without considering the absorption and reflection of printed grid lines and electrodes, so as to improve photoelectric conversion efficiency and service life, low softening point, and raw materials The effect of less ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

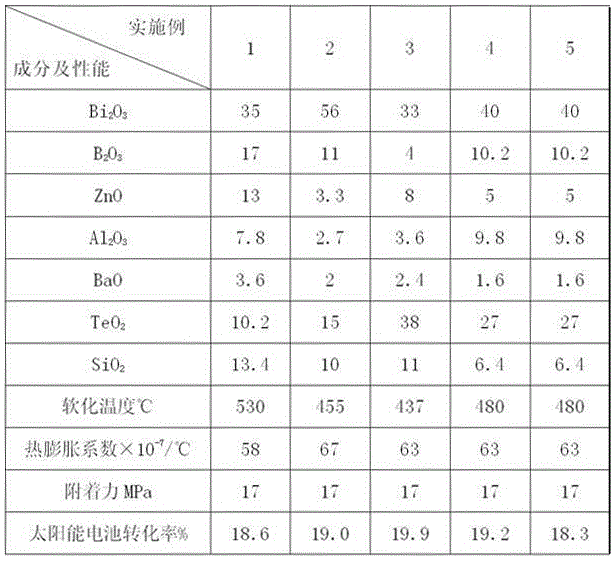

[0023] Batching 1000g according to the formula of Example 1 in Table 1, and mix evenly, put the mixture in the platinum crucible, cover the platinum crucible and put it into a silicon carbide rod resistance furnace for heating and melting, the heating and melting temperature is 1050 ° C, and the heat preservation is 30 Minutes; the melted glass liquid is immediately poured into pure water, and after water quenching, fine particles are formed, and dried in an oven at 120°C under normal pressure; the dried glass particles are crushed with a jet mill until the particle size D90 is below 8um , and then use a ball mill to further pulverize to a particle size of D90 to below 5um; classify the obtained glass powder with a particle size of below 5um with an air flow separator to obtain a low melting point with a particle size of 0.3-4um and a particle size span of less than 1.3 Glass powder, the performance parameters of the test glass powder are shown in Table 1, the prepared glass po...

Embodiment 2

[0025] Batching 1000g according to the formula of Example 2 in Table 1, and mix evenly, put the mixture in the platinum crucible, cover the platinum crucible and put it into a silicon carbide rod resistance furnace for heating and melting, the heating and melting temperature is 1000 ° C, and the heat preservation is 40 Minutes; the melted glass liquid is immediately poured into pure water, and after water quenching, fine particles are formed, and dried in an oven at 120°C under normal pressure; the dried glass particles are crushed with a jet mill until the particle size D90 is below 8um , and then use a ball mill to further pulverize to a particle size of D90 to below 5um; classify the obtained glass powder with a particle size of below 5um with an air flow separator to obtain a low melting point with a particle size of 0.3-4um and a particle size span of less than 1.3 Glass powder, the performance parameters of the test glass powder are shown in Table 1, the prepared glass po...

Embodiment 3

[0027]Batching 1000g according to the formula of Example 3 in Table 1, and mix evenly, put the mixture in the platinum crucible, cover the platinum crucible and put it into a silicon carbide rod resistance furnace for heating and melting, the heating and melting temperature is 1000 ° C, and the heat preservation is 50 Minutes; the melted glass liquid is immediately poured into pure water, and after water quenching, fine particles are formed, and dried in an oven at 120°C under normal pressure; the dried glass particles are crushed with a jet mill until the particle size D90 is below 8um , and then use a ball mill to further pulverize to a particle size of D90 to below 5um; classify the obtained glass powder with a particle size of below 5um with an air flow separator to obtain a low melting point with a particle size of 0.3-4um and a particle size span of less than 1.3 Glass powder, the performance parameters of the test glass powder are shown in Table 1, the prepared glass pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com