Method for producing diesel oil from Fischer-Tropsch synthetic oil

A Fischer-Tropsch synthetic oil and Fischer-Tropsch synthesis technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of low diesel density, high freezing point, and can not meet the requirements of vehicle diesel indicators, etc. The effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The mixed oil LLH-1 of LTFT-LO-1, LTFT-HO-1 and HTFT-1 is used as the raw material for hydrofining reaction, wherein the LTFT-LO-1, LTFT-HO-1 and HTFT-1 are The products prepared under the same Fischer-Tropsch synthesis reaction conditions were isolated, and their properties are shown in Table 1. Wherein, the weight ratio of LTFT-LO-1:LTFT-HO-1:LTFT-HW-1 is 10:3:12.

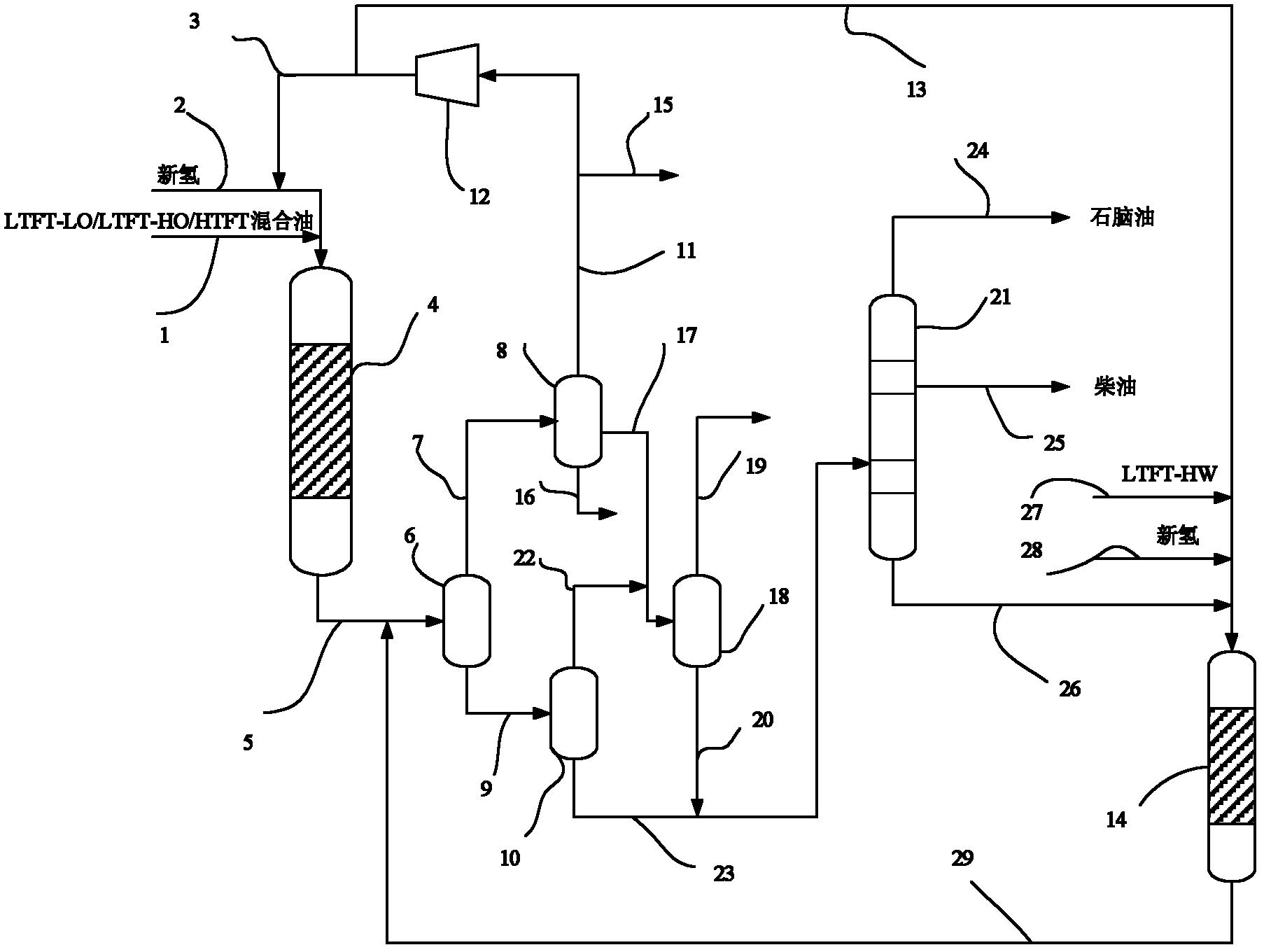

[0055] Such as figure 1 As shown, the hydrofinishing product is separated into hydrogen-rich gas, water and liquid hydrocarbons through the separation system, the hydrogen-rich gas is circulated back to the reaction system, and the water is discharged from the device. The liquid hydrocarbons enter the fractionation tower to distill the naphtha fraction 350°C, among which the naphtha fraction and the diesel fraction are used as products. The wax oil fraction >350°C fractionated by the fractionating tower is mixed with LTFT-HW-1 (see Table 1 for properties) and then enters the hydrocracking reactor for hyd...

Embodiment 2

[0064] The mixed oil LLH-2 of LTFT-LO-2, LTFT-HO-2 and HTFT-2 is used as the raw material for hydrofining reaction, wherein the LTFT-LO-2, LTFT-HO-2 and HTFT-2 are The products prepared under the same Fischer-Tropsch synthesis reaction conditions were isolated, and their properties are shown in Table 2. Wherein, the weight ratio of LTFT-LO-2:LTFT-HO-2:LTFT-HW-2 is 5.1:2.6:8.9.

[0065] Such as figure 1 As shown, the hydrofinishing product is separated into hydrogen-rich gas, water and liquid hydrocarbons through the separation system, and the hydrogen-rich gas and water are discharged from the device. The liquid hydrocarbons enter the fractionation tower to distill the naphtha fraction 350°C, among which the naphtha fraction and the diesel fraction are used as products. The wax oil fraction >350°C fractionated by the fractionating tower is mixed with LTFT-HW-2 (see Table 1 for properties) and then enters the hydrocracking reactor for hydrocracking reaction, and the hydrocrac...

Embodiment 3

[0070] The mixed oil LLH-3 of LTFT-LO-3, LTFT-HO-3 and HTFT-3 is used as the raw material for hydrofining reaction, wherein the LTFT-LO-3, LTFT-HO-3 and HTFT-3 are The products prepared under the same Fischer-Tropsch synthesis reaction conditions were isolated, and their properties are shown in Table 3. Wherein, the weight ratio of LTFT-LO-3:LTFT-HO-3:LTFT-HW-3 is 6.2:2.3:10.2.

[0071] Such as figure 1 As shown, the hydrofinishing product is separated into hydrogen-rich gas, water and liquid hydrocarbons through the separation system, and the hydrogen-rich gas and water are discharged from the device. The liquid hydrocarbons enter the fractionation tower to distill the naphtha fraction at 350°C, among which the naphtha fraction and the diesel fraction are used as products. The wax oil fraction >350°C fractionated by the fractionating tower is mixed with LTFT-HW-3 (see Table 1 for properties) and then enters the hydrocracking reactor for hydrocracking reaction, and the hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com