Metal cutting liquid and processing technology of metal processing liquid

A metal cutting fluid and production process technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of heavy metals and nitrite ions that are harmful to the human body, and fail to meet the requirements of environmental protection, and achieve good chemical stability. The effect of service life and high technical content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

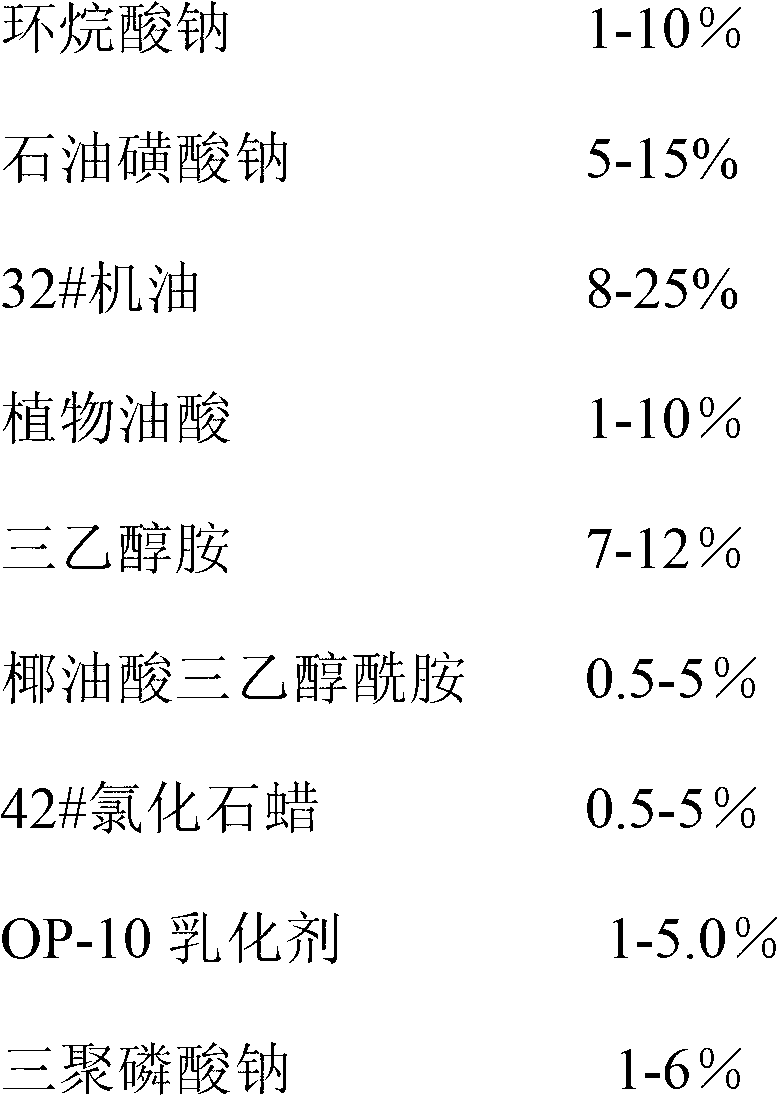

[0038] Metal cutting fluid, including the following components by mass percentage:

[0039]

[0040]

[0041] 2. Production process:

[0042] A: Synthetic triethanolamine oleic acid soap

[0043] Add triethanolamine and oleic acid to the reaction kettle according to the specified amount, start stirring, and slowly raise the temperature for 3-5°C / 10 minutes to 80±1°C. The temperature rise rate and the controlled temperature do not produce different reactants, and the lubrication of the finished product And anti-rust performance is different, heat preservation reaction at this temperature for 4 hours, to obtain viscous triethanolamine oleic acid soap, standby.

[0044] B: Add 400 kg of deionized water to the reactor, then add a specified amount of sodium tripolyphosphate into the reactor, start stirring, slowly raise the temperature to 60°C, and add triethanolamine oleic acid soap after the sodium tripolyphosphate is completely dissolved. After the oleic acid soap is com...

Embodiment 2

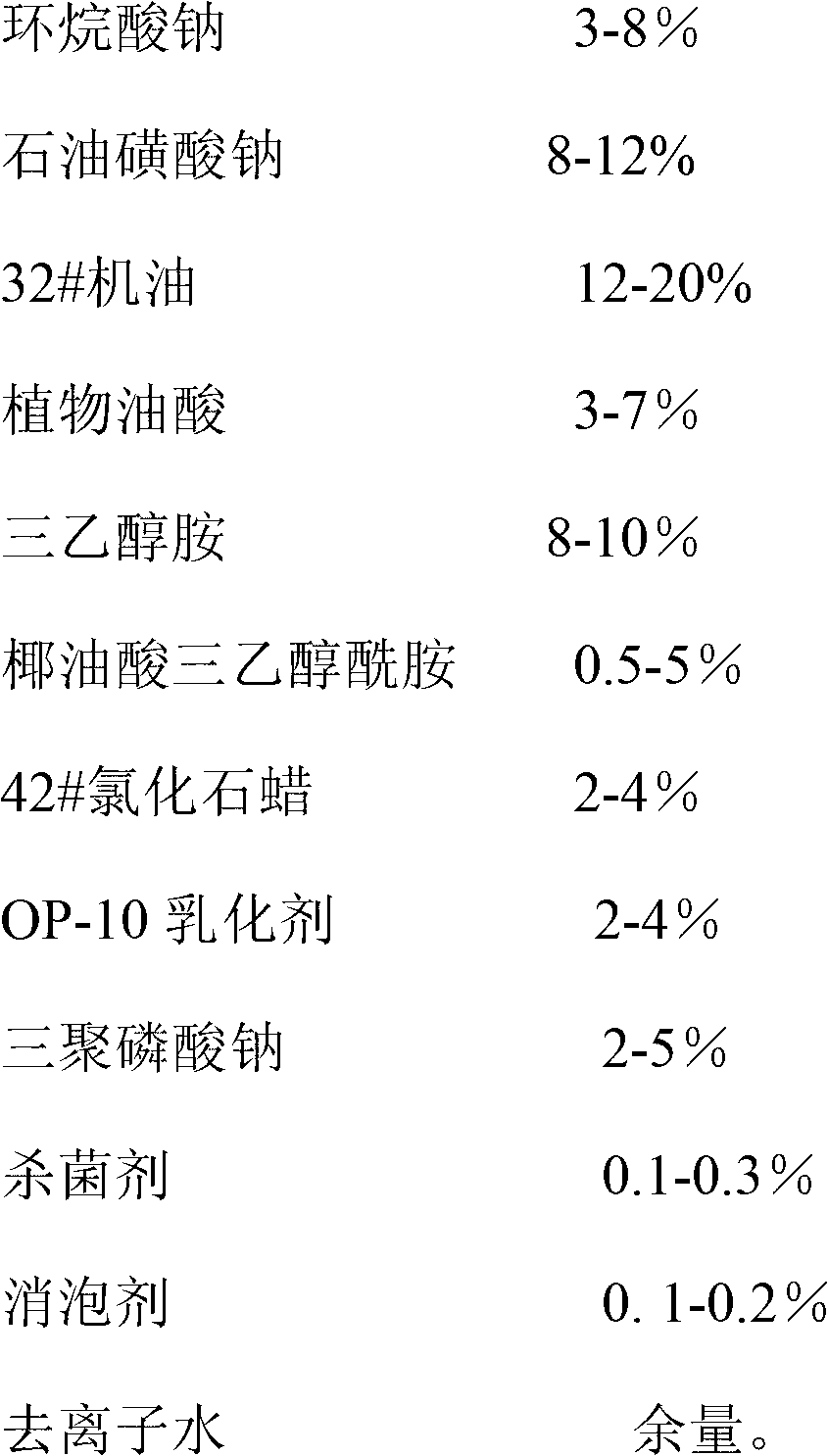

[0047] Metal cutting fluid, including the following components by mass percentage:

[0048]

[0049]

[0050] The production process of metal cutting fluid comprises the following steps:

[0051] A: Synthetic triethanolamine oleic acid soap

[0052] Add the above-mentioned triethanolamine and oleic acid in mass percentage to the reaction vessel, stir, raise the temperature to 81°C for 3°C / 10 minutes, and keep the temperature for 3 hours to obtain triethanolamine oleic acid soap for later use;

[0053] B: Add 300 kg of deionized water into the reaction vessel, then add the above-mentioned sodium tripolyphosphate in terms of mass percentage, stir, heat up to 55°C, add triethanolamine oleic acid soap after the sodium tripolyphosphate is completely dissolved, wait After the oleic acid soap is completely dissolved, add the above-mentioned other components in terms of mass percentages in the above order, and after all the substances are dissolved, raise the temperature of the...

Embodiment 3

[0056] Metal cutting fluid, including the following components by mass percentage:

[0057]

[0058]

[0059] The production process of metal cutting fluid comprises the following steps:

[0060] A: Synthetic triethanolamine oleic acid soap

[0061] Add the above-mentioned triethanolamine and oleic acid in mass percentages into the reaction vessel, stir, raise the temperature to 79°C for 5°C / 10 minutes, and keep warm for 4.5 hours to obtain triethanolamine oleic acid soap for later use;

[0062] B: Add 500 kg of deionized water to the reaction vessel, then add the above-mentioned sodium tripolyphosphate in terms of mass percentage, stir, heat up to 55°C, and add triethanolamine oleic acid soap after the sodium tripolyphosphate is completely decomposed. After the oleic acid soap is completely dissolved, add the above-mentioned other components in terms of mass percentages in the above order, and after all the substances are dissolved, raise the temperature of the entire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com