Method for measuring contents of strontium and aluminum in strontium chloride injection by graphite furnace atomic absorption spectrometry

A technology of graphite furnace atomic and absorption spectroscopy, which is applied in the field of measuring aluminum content and strontium in strontium chloride injection, can solve the problems of large initial investment, high instrument price, and inability to perform valence analysis, and achieve low investment and operating costs , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

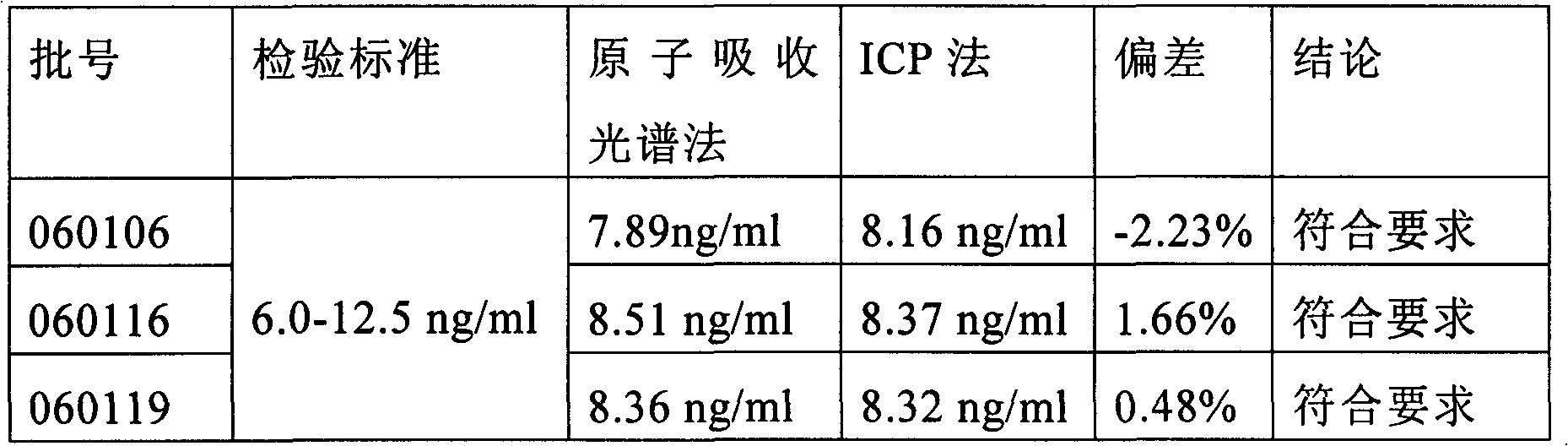

[0065] Utilize graphite furnace atomic absorption spectrometry to measure the content of strontium in the strontium chloride injection, specifically comprise the following steps:

[0066] (1) Precisely draw 0.1ml of strontium standard solution with a concentration of 1.0g / L in a 10ml volumetric flask, dilute to the mark with 1% hydrochloric acid, shake well, and obtain a stock solution;

[0067] (2) Draw 0ml, 0.5ml, 1.0ml, 1.5ml, 2.0ml stock solutions into 10ml volumetric flasks respectively, and dilute to the mark with 1% hydrochloric acid to obtain concentrations of 0μg / l, 5μg / l, 10μg / l, 15μg / l, 20μg / l strontium standard solution;

[0068] (3) Accurately absorb strontium chloride, dilute it 106 times in two steps with 1% hydrochloric acid, shake well, and obtain the test product;

[0069] (4) Turn on the atomic absorption spectrophotometer to preheat the strontium lamp for more than 30 minutes;

[0070] (5) After the atomic absorption spectrophotometer is stable, measure t...

Embodiment 2

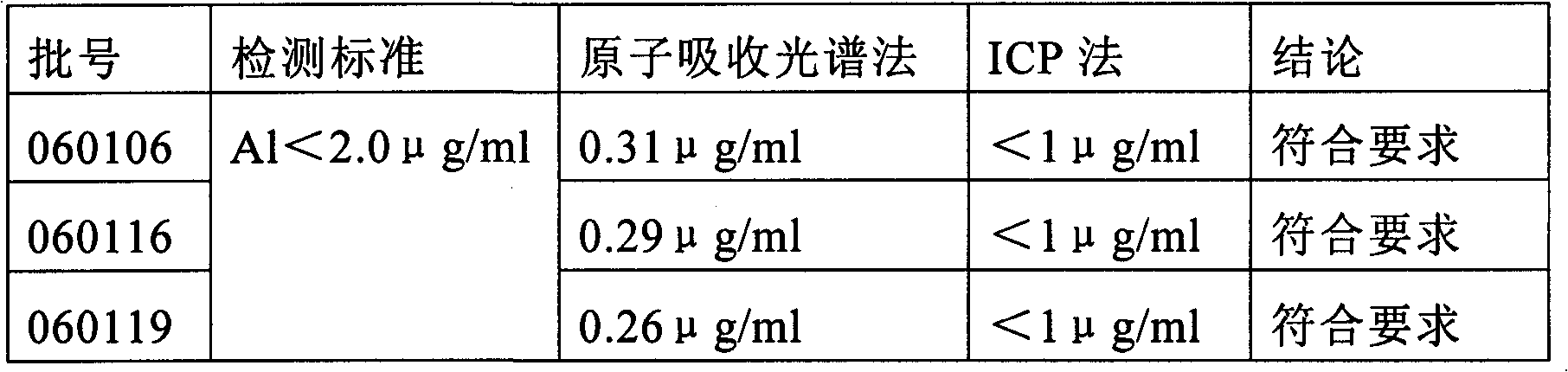

[0101] Utilize graphite furnace atomic absorption spectrometry to measure the content of aluminum in the strontium chloride injection, specifically comprise the following steps:

[0102] (1) Precisely draw 0.1ml of aluminum standard solution with a concentration of 1.0g / L in a 10ml volumetric flask, dilute to the mark with ultrapure water, shake well, and obtain the stock solution;

[0103] (2) Pipette 0ml, 0.5ml, 1.0ml, 1.5ml, 2.0ml stock solutions into 10ml volumetric flasks respectively, and dilute to the mark with ultrapure water to obtain concentrations of 0μg / l, 5μg / l, 10μg / l, 15μg / l, 20g / l aluminum standard solution;

[0104] (3) Precisely absorb strontium chloride, dilute it 50 times with ultrapure water, shake it up, and obtain the test product;

[0105] (4) Turn on the atomic absorption spectrophotometer to preheat the aluminum lamp for more than 30 minutes;

[0106] (5) After the atomic absorption spectrophotometer is stable, measure the absorbance of the standard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com